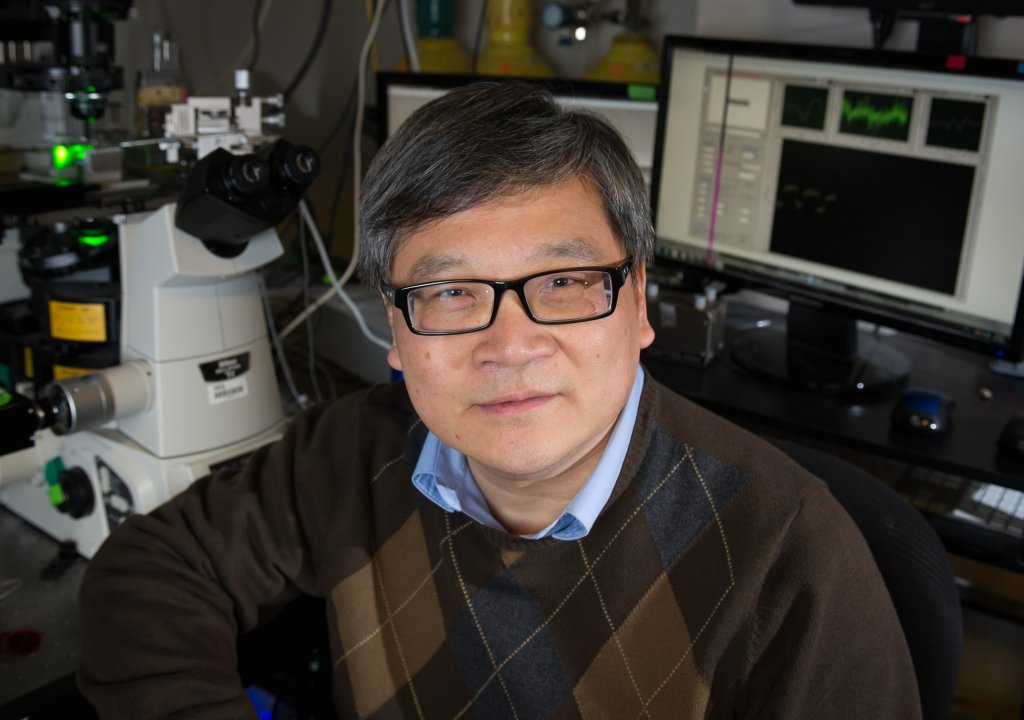

H. Jerry Qi is a professor and the Woodruff Faculty Fellow in the George W. Woodruff School of Mechanical Engineering at Georgia Institute of Technology. He received his bachelor degrees (dual degree), master and Ph.D. degree from Tsinghua University (Beijing, China) and a ScD degree from Massachusetts Institute of Technology (Boston, MA, USA). After one year postdoc at MIT, he joined University of Colorado Boulder as an assistant professor in 2004, and was promoted to associate professor with tenure in 2010. He joined Georgia Tech in 2014 as an associate professor with tenure and was promoted to a full professor in 2016. Qi is a recipient of NSF CAREER award (2007). He is a member of Board of Directors for the Society of Engineering Science. In 2015, he was elected to an ASME Fellow. The research in Qi's group is in the general area of soft active materials, with a focus on 1) 3D printing of soft active materials to enable 4D printing methods; and 2) recycling of thermosetting polymers. The material systems include: shape memory polymers, light activated polymers, vitrimers. On 3D printing, they developed a wide spectrum of 3D printing capability, including: multIMaTerial inkjet 3D printing, digit light process (DLP) 3D printing, direct ink write (DIW) 3D printing, and fused deposition modeling (FDM) 3D printing. These printers allow his group to develop new 3D printing materials to meet the different challenging requirements. For thermosetting polymer recycling, his group developed methods that allow 100% recycling carbon fiber reinforced composites and electronic packaging materials. Although his group develops different novel applications, his work also relies on the understanding and modeling of material structure and properties under environmental stimuli, such as temperature, light, etc, and during material processing, such as 3D printing. Constitutive model developments are typically based on the observations from experiments and are then integrated with finite element through user material subroutines so that these models can be used to solve complicated 3D multiphysics problems involving nonlinear mechanics. A notable example is their recent pioneer work on 4D printing, where soft active materials is integrated with 3D printing to enable shape change (or time in shape forming process). Recently, his developed a state-of-the-art hybrid 3D printing station, which allows his group to integrate different polymers and conduct inks into one system. Currently, his group is working on using this printing station for a variety of applications, including printed 3D electronics, printed soft robots, etc.

Additional Research

Additive/Advanced Manufacturing; micro and nanomechanics; Recycling; Soft Materials; Conducting Polymers

H. Jerry