New Implant May Help Patients Regenerate Their Own Heart Valves

A 3D-printed, bioresorbable heart valve promotes tissue regeneration, potentially eliminating the need for repeated surgeries for adult and pediatric heart patients.

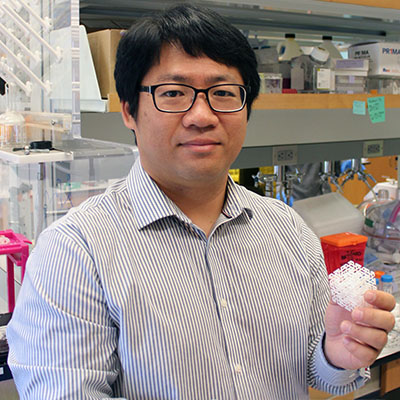

The bioresorbable heart valve (yellow) that promotes tissue regeneration and a 3D-printed heart model.

Every year, more than 5 million people in the U.S. are diagnosed with heart valve disease, but this condition has no effective long-term treatment. When a person’s heart valve is severely damaged by a birth defect, lifestyle, or aging, blood flow is disrupted. If left untreated, there can be fatal complications.

Valve replacement and repair are the only methods of managing severe valvular heart disease, but both often require repeated surgeries that are expensive, disruptive, and life-threatening. Most replacement valves are made of animal tissue and last up to 10 or 15 years before they must be replaced. For pediatric patients, solutions are extremely limited and can require multiple reinterventions.

Now, Georgia Tech researchers have created a 3D-printed heart valve made of bioresorbable materials and designed to fit an individual patient’s unique anatomy. Once implanted, the valves will be absorbed by the body and replaced by new tissue that will perform the function that the device once served.

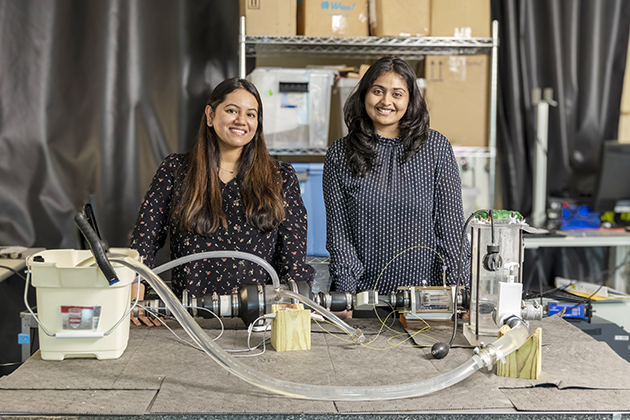

Research scientist Sanchita Bhat and Ph.D. student Srujana Joshi use a heart simulation setup to test the heart valve prototypes. The system matches a real heart’s physiological conditions and can mimic the pressure and flow conditions of an individual patient's heart.

The invention comes out of the labs of faculty members Lakshmi Prasad Dasi and Scott Hollister in the Wallace H. Coulter Department of Biomedical Engineering (BME) at Georgia Tech and Emory.

“This technology is very different from most existing heart valves, and we believe it represents a paradigm shift,” said Dasi, the Rozelle Vanda Wesley Professor in BME. “We are moving away from using animal tissue devices that don’t last and aren’t sustainable, and into a new era where a heart valve can regenerate inside the patient.”

Dasi is a leading researcher in heart valve function and mechanics, while Hollister is a top expert in tissue engineering and 3D printing for pediatric medical devices. They brought their teams together to create a first-of-its-kind technology.

“In pediatrics, one of the biggest challenges is that kids grow, and their heart valves change size over time,” said Hollister, who is professor and Patsy and Alan Dorris Chair in Pediatric Technology and associate chair for Translational Research. “Because of this, children must undergo multiple surgeries to repair their valves as they grow. With this new technology, the patient can potentially grow new valve tissue and not have to worry about multiple valve replacements in the future.”

Growing Into the Heart

Although 3D-printed heart valves currently exist and bioresorbable materials have been used for implants before, this is the first time the two technologies have been combined to create one device with a resorbable, shape memory material.

“From the start, the vision for the project was to move away from the one-size-fits-most approach that has been the status quo for heart valve design and manufacturing, and toward a patient-specific implant that can outlast current devices,” explained Sanchita Bhat, a research scientist in Dasi’s lab who first became involved in the project as a Ph.D. student.

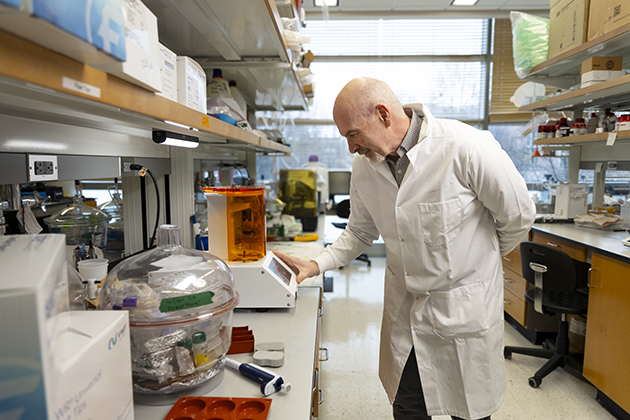

Hollister and his team use special 3D printers to create devices made of biocompatible materials (orange appliance on the left).

The initial research involved finding the right material and testing different prototypes. The team’s heart valve is 3D-printed using a biocompatible material called poly(glycerol dodecanedioate).

The valve has shape memory, so it can be folded and delivered via a catheter, rather than open heart surgery. Once it is implanted and reaches body temperature, the device will refold into its original shape. The material will then signal to the body to make its own new tissue to replace the device. The original device will absorb completely in a few months.

Srujana Joshi, a fourth-year Ph.D. student in Dasi’s lab, has played a major role in testing and analyzing the heart valve’s design and performance.

“Once you have an idea for an implant, it takes a lot of fine-tuning and optimization to arrive at the right design, material, and manufacturing parameters that work,” Joshi said. “It is an iterative process, and we’ve been testing these aspects in our systems to make sure the valves are doing what they're supposed to do.”

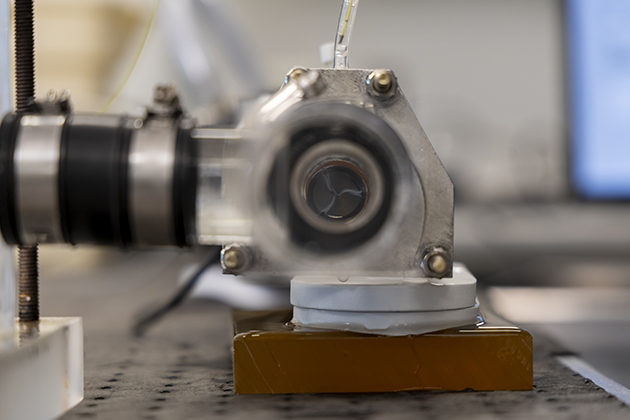

Bhat and Joshi are currently testing the heart valve’s physical durability with both computational models and benchtop studies. Dasi’s lab has a heart simulation setup that matches a real heart’s physiological conditions and can mimic the pressure and flow conditions of an individual patient's heart. An additional machine tests the valve’s mechanical durability by putting it through millions of heart cycles in a short time.

“We think this device represents a paradigm shift. We are moving away from using animal tissue devices that don’t last and aren’t sustainable, and into a new era where a heart valve can regenerate inside the patient.” — Prasad Dasi

A Paradigm-Shifting Technology

The heart valve prototype can be seen inside a heart simulation setup that is used to test its durability.

According to the researchers, it is an enormous challenge to create a material that can carry out a heart valve’s rigorous function, while also encouraging new tissue to develop and take over. Also, new medical devices undergo a long journey from bench to bedside, and several key milestones must be met.

The researchers hope their technology can revolutionize treatment for heart valve patients — and that it will usher in a new era of more tissue-engineered devices.

According to Dasi and Hollister, implants aren’t developed for pediatric populations as often as they are for adults. This is due to child diseases being rarer, along with the high cost of manufacturing. The researchers think that combining bioresorbable materials with 3D printing and manufacturing could be the key to developing better pediatric devices.

“The hope is that we will start with the pediatric patients who can benefit from this technology when there is no other treatment available to them,” Dasi said. “Then we hope to show, over time, that there’s no reason why all valves shouldn’t be made this way.”

Note: Harsha Ramaraju (research scientist), Ryan Akman (research scientist), Adam Verga (Ph.D. candidate), David Rozen (undergraduate student), Satheesh Kumar Harikrishnan (former research engineer), and Hieu Bui (former postdoctoral fellow) also played a major role in developing this technology.

Funding: Development of the bioresorbable material was supported by the National Institutes of Health grant number NIH/NHLBI R21-126004. This research received early financial support from the Georgia Research Alliance.

Writer and Media Contact: Catherine Barzler | catherine.barzler@gatech.edu

Photos and Video: Christopher McKenney | Related Stories Photos: Courtesy of Georgia Tech

Copy Editor: Stacy Braukman

Design: Josie Giles

Series Design: Stephanie Stephens

About Georgia Tech Commercialization

Georgia Tech Commercialization provides a foundation for faculty seeking to translate the Institute's leading-edge research into real-world applications. Commercialization encompasses four pivotal units: CREATE-X, VentureLab, Quadrant-i, and Technology Licensing. These units empower students and faculty to launch startups, provide comprehensive commercialization support, manage intellectual property, and facilitate the transformation of research into viable businesses. The Office of Commercialization’s mission is to provide world-class commercialization services, catalyzing research and innovation to improve the human condition, and enhancing Georgia Tech's position as a leader in technology and entrepreneurial impact.

Paradigm Shifters Series

New Smart Charger May Pave the Way for More EVs

The revolutionary system allows for cheaper, carbon-free charging and aims to reduce the burden on the electric grid as more EVs enter the roadway.

World’s Smallest Robotic Guidewire Improves Surgical Precision

The robot is a groundbreaking surgical device that helps doctors navigate blood vessels with precision during procedures like angioplasty.

Researchers Create a Low-Emission, Fuel-Flexible Combustion System

This new combustor uses carbon-free fuels that will power planes and heat buildings.

New Wearable Device Monitors Joint Pain

Arthroba enables everyday people and their doctors to follow their joint health in real time.

New Implant May Help Patients Regenerate Their Own Heart Valves

Georgia Tech researchers have developed a groundbreaking 3D-printed, bioresorbable heart valve that promotes tissue regeneration.

Researchers Build Stable Solar Panel Without Silicon

Solar power as an electricity source is growing in the U.S., but scientists are still trying to make the solar panel production process more efficient.

Startup Targets Building Energy Inefficiencies With AI and Drones

Lamarr.AI uses drones, AI, and thermal imaging to identify energy inefficiencies in buildings, offering a faster, safer, and more accurate solution.

This Pacifier Could Monitor Babies’ Vitals in the NICU

The baby-friendly device measures electrolyte levels in real time, eliminating the need for repeated, painful blood draws.

This Small Sensor Could Make Huge Impacts on Brain Injury Treatment

Researchers develop a tinier sensor for less invasive intracranial monitoring.

Driving Change: Artificial Intelligence Improves Outcomes of Heart Valve Patients

Driving Change: Artificial Intelligence Improves Outcomes of Heart Valve Patients  Hollister Lab Develops Blueprint for 3D Printed Personalized Medical Devices

Hollister Lab Develops Blueprint for 3D Printed Personalized Medical Devices  Hollister Lab Develops 3D Printing for Soft Tissue Engineering

Hollister Lab Develops 3D Printing for Soft Tissue Engineering