Innovation at Scale: Georgia Tech Unveils New Roll-to-Roll Manufacturing Pilot Facility

Oct 03, 2024 —

Partners of the facility gathered for an official ribbon cutting ceremony. From left to right: Eric Vogel, Hightower Professor in MSE and executive director for the Institute for Matter and Systems; Devesh Ranjan, Eugene C. Gwaltney, Jr. school chair and professor in the George W. Woodruff School of Mechanical Engineering; Julia Kubanek, vice president of Interdisciplinary Research; Tequila Harris, professor in the Woodruff School and facility leader; Christine Conwell, interim executive director for the Strategic Energy Institute; Tim Liewen, interim executive vice president for Research; Thomas Kurfess, Regent's Professor in the Woodruff School and executive director of the Georgia Tech Manufacturing Institute; J. Carson Meredith, professor and James Preston Harris Faculty Fellow in the School of Chemical and Biomolecular Engineering, executive director of the Renewable Bioproducts Institute. Photo: Christopher McKenney.

Whether it’s developing new products, reducing costs, or increasing accessibility, innovations in manufacturing stand to improve the lives of companies and consumers alike. Georgia Tech recently took another step toward ensuring those innovations make it from lab to market with the launch of a Modular Pilot Scale Roll-to-Roll Manufacturing Facility.

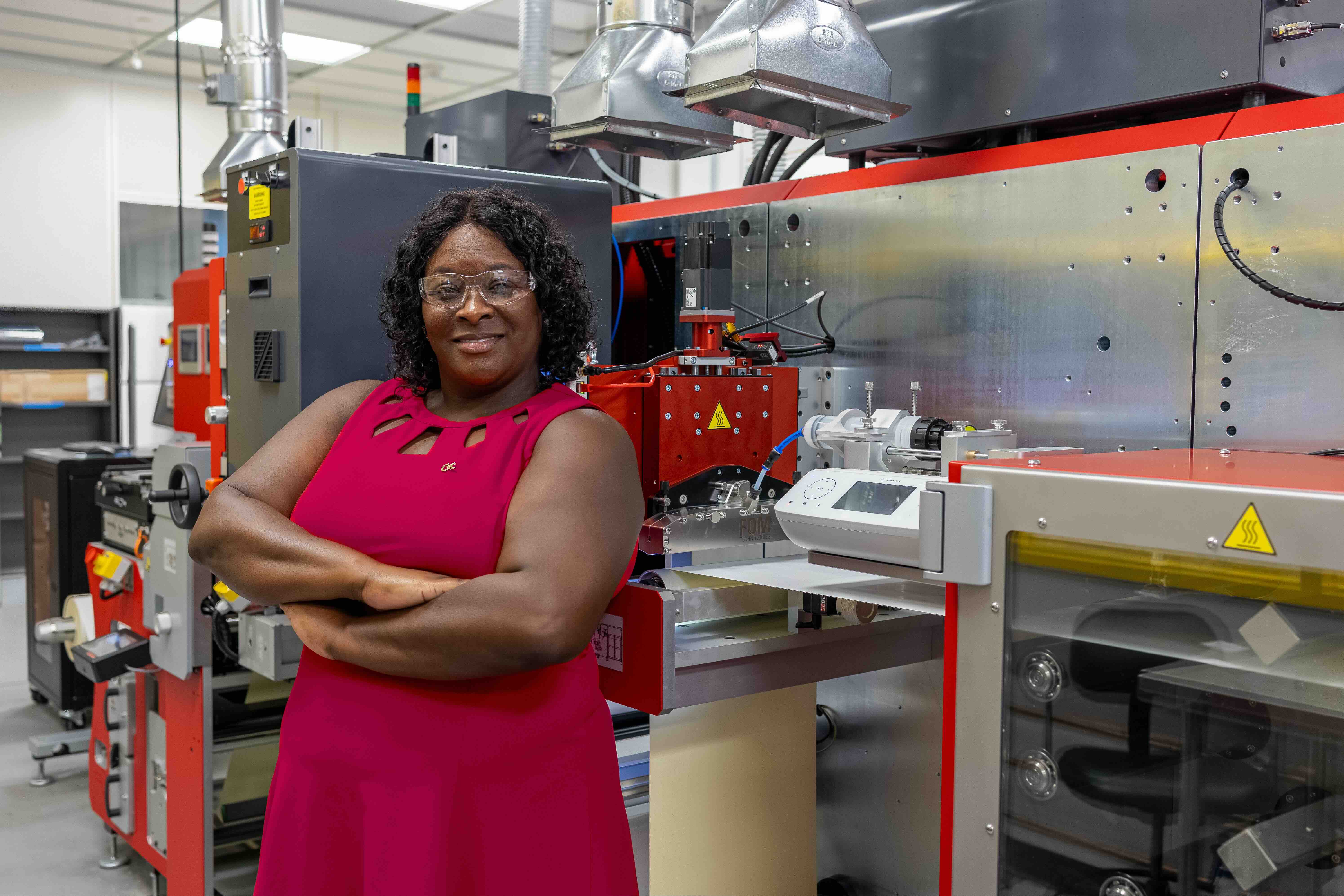

“As researchers develop new materials, one of the key aspects we’re missing is how to make them at scale. This is a major oversight because if we can’t make them at scale, we can’t transition from basic research to commercialization,” said Tequila Harris, a professor in the George W. Woodruff School of Mechanical Engineering. “With this new facility, we can prove our discoveries beyond lab-scale studies — and can go from materials innovation to product development at scale.”

Led by Harris, the new facility is the result of a partnership between the Georgia Tech Manufacturing Institute (GTMI), the Strategic Energy Institute, and the Woodruff School. As a pilot facility, it will serve as a testbed for scaling up manufacturing research open for Georgia Tech researchers as well as academic, government, and industry partners around the world.

“The larger vision I see at Georgia Tech involves innovation in manufacturing for large-scale industries,” said Georgia Tech’s Interim Executive Vice President for Research Tim Lieuwen at the facility’s unveiling event on Sept. 19. “It’s crucial that we’re innovating in basic science and technology, but we also need to be innovating in large-scale manufacturing.”

Roll-to-roll (R2R) manufacturing transforms flexible rolls of substrate materials, such as paper, metal foils, and plastics, into more complex, transportable rolls upon coating the surface with one or more fluids, such as inks, suspensions, and solutions, which are subsequently dried or cured on the base substrate. Its high yield and efficiency make R2R an ideal method for the sustainable, large-scale production of components for solar cells, batteries, flexible electronics, and separations — all industries that have expanded in Georgia in recent years.

“As a state institution, we’re ultimately here to serve our state,” said Lieuwen, who is also Regents’ Professor and David S. Lewis Jr. Chair in the Daniel Guggenheim School of Aerospace Engineering. “We’re seeing Georgia emerge as the national leader in terms of recruiting corporate investments in this space and in industries that will be served by this facility.”

Roll-to-Roll Innovations

The R2R process is similar to the production of newspapers, where a large roll of blank paper goes through a series of rollers printing text and photos. “The roll-to-roll aspect is the process of using a specialized tool to force fluid onto a moving surface,” says Harris. It’s one of the fastest-growing methods for producing thin film materials — photovoltaics used in solar cells, transistors in flexible electronics, and micro-batteries, for example — at a large scale.

Harris’s group works to develop novel manufacturing tools, with a particular focus on understanding and improving the dynamics of thin film manufacturing to increase efficiency and minimize waste. Her group is particularly interested in slot die coating, an R2R technique where a liquid material is precisely deposited onto a substrate through a narrow slot. With the new pilot facility, researchers like Harris will be able to take their work to the next level.

“Slot die coating on a roll-to-roll can handle the broadest viscosity range of most coating methods. Therefore, you can process a lot of different materials very quickly and easily,” says Harris. “It’s one of the fastest-growing technologies in the U.S. — and currently, this is the most advanced modular pilot scale facility at an academic university in the United States.”

“Georgia Tech is way ahead of the curve in terms of our facilities,” says GTMI Executive Director and Regents’ Professor Thomas Kurfess. “This will grow our capability in the battery area, membranes, flexible electronics, and more to allow us to support the development of new technologies.”

“As technologies around cleantech continue to advance at an unprecedented pace, pilot manufacturing facilities provide a critical bridge between innovative benchtop research and commercial-scale production and manufacturing,” says Christine Conwell, interim executive director of the Strategic Energy Institute. “We are excited about the opportunities this R2R facility will provide to the Georgia Tech energy community and our industry partners.”

Tequila Harris, professor in the George W. Woodruff School of Mechanical Engineering, next to the modular R2R equipment. Photo: Christopher McKenney.

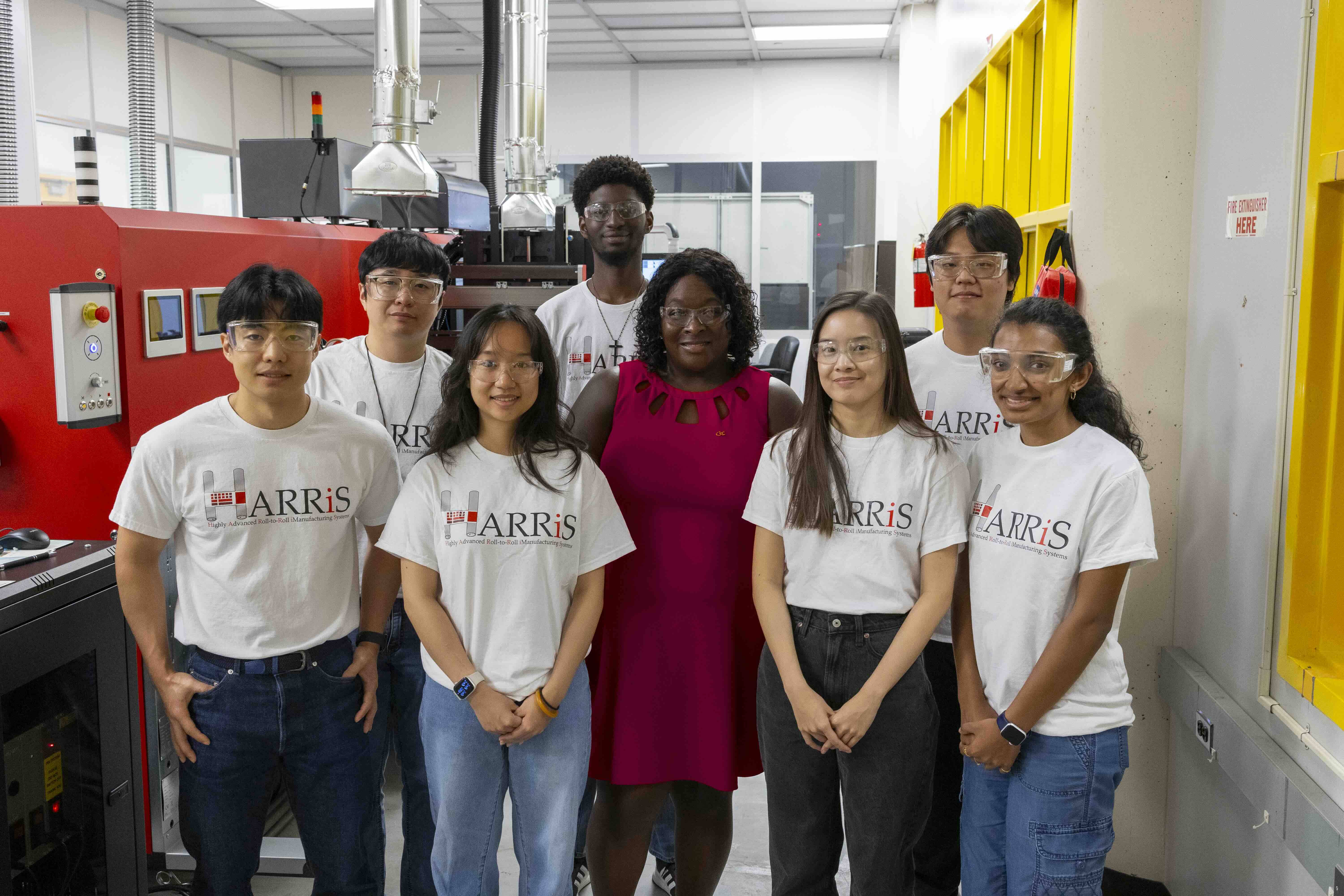

The Highly Advanced Roll-to-Roll iManufacturing Systems (HARRiS) research group in the new R2R facility. Photo: Christopher McKenney.

Audra Davidson

Research Communications Program Manager

Georgia Tech Manufacturing Institute