Researchers Build Stable Solar Panel Without Silicon

By adding titanium to perovskite crystals, researchers have made solar cells more durable.

Solar power as an electricity source is growing in the United States, with 7% of Americans using it to run their homes. But scientists are still trying to make the solar panel production process more efficient.

Solar panels are composed of dozens of solar cells, which are usually made of silicon. While silicon is the standard, producing and processing it is energy-intensive, making it costly to build new solar panel manufacturing facilities. Most of the world’s solar cells are made in China, which has an abundance of silicon. To increase solar cell production in the U.S., a new, easily produced domestic material is needed.

“We’re developing technologies that we can easily produce without spending a ton of money on expensive equipment,” said Juan-Pablo Correa-Baena, an associate professor in the School of Materials Science and Engineering.

“We’re developing technologies that we can easily produce without spending a ton of money on expensive equipment.” — Juan-Pablo Correa-Baena

For years, Correa-Baena’s research group has explored using perovskite crystals as an alternative to silicon. A promising and prevalent replacement, perovskite is made of iodine atoms, lead, and organic elements. It is also as efficient as silicon.

However, perovskite has one major drawback: It lasts only about 5% as long as a silicon cell. Compared to silicon’s 20 years, perovskite-made cells deteriorate after a year of use. The material is especially sensitive to hot summer temperatures and can decompose before the solar panel can help a homeowner save on energy costs.

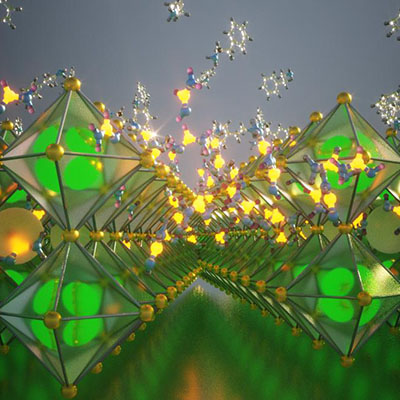

Using a new technology, Correa-Baena’s lab has found a way to stabilize the perovskite solar cells, which are built like a battery. They have one positive and one negative electrode, with the perovskite cell sandwiched between them. Before placing a positive electrode at the top of the cell, the researchers exposed the perovskite to titanium gas under a light vacuum. This process, known as vapor-phase infiltration, embeds titanium into the top layer of the solar cell. The technology is under patent review.

“We've made one of the layers that causes the longevity issue more robust and resilient to especially high temperatures,” Correa-Baena said. “In this process of inserting titanium, we can prevent the degradation process, and then we can test the solar cell on roofs or anywhere.”

Ultimately, the shift from silicon to perovskite crystals in solar cell production could transform the solar industry. The innovative stabilization technique developed by Correa-Baena's team addresses the primary drawback of perovskite cells, making them more viable for long-term use. This progress not only enhances the potential for domestic solar cell production but also supports the broader goal of increasing renewable energy adoption in the United States.

Funding courtesy of U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy Solar Energy Technologies Office.

A student deposits halide perovskite materials via solution processing.

A student processes materials for solar cells and quantum application.

Writer and Media Contact: Tess Malone | tess.malone@gatech.edu

Photos and Video: Christopher McKenney

Copy Editor: Stacy Braukman

Design: Josie Giles

Series Design: Stephanie Stephens

About Georgia Tech Commercialization

Georgia Tech Commercialization provides a foundation for faculty seeking to translate the Institute's leading-edge research into real-world applications. Commercialization encompasses four pivotal units: CREATE-X, VentureLab, Quadrant-i, and Technology Licensing. These units empower students and faculty to launch startups, provide comprehensive commercialization support, manage intellectual property, and facilitate the transformation of research into viable businesses. The Office of Commercialization’s mission is to provide world-class commercialization services, catalyzing research and innovation to improve the human condition, and enhancing Georgia Tech's position as a leader in technology and entrepreneurial impact.

Paradigm Shifters Series

New Smart Charger May Pave the Way for More EVs

The revolutionary system allows for cheaper, carbon-free charging and aims to reduce the burden on the electric grid as more EVs enter the roadway.

World’s Smallest Robotic Guidewire Improves Surgical Precision

The robot is a groundbreaking surgical device that helps doctors navigate blood vessels with precision during procedures like angioplasty.

Researchers Create a Low-Emission, Fuel-Flexible Combustion System

This new combustor uses carbon-free fuels that will power planes and heat buildings.

New Wearable Device Monitors Joint Pain

Arthroba enables everyday people and their doctors to follow their joint health in real time.

New Implant May Help Patients Regenerate Their Own Heart Valves

Georgia Tech researchers have developed a groundbreaking 3D-printed, bioresorbable heart valve that promotes tissue regeneration.

Researchers Build Stable Solar Panel Without Silicon

Solar power as an electricity source is growing in the U.S., but scientists are still trying to make the solar panel production process more efficient.

Startup Targets Building Energy Inefficiencies With AI and Drones

Lamarr.AI uses drones, AI, and thermal imaging to identify energy inefficiencies in buildings, offering a faster, safer, and more accurate solution.

This Pacifier Could Monitor Babies’ Vitals in the NICU

The baby-friendly device measures electrolyte levels in real time, eliminating the need for repeated, painful blood draws.

This Small Sensor Could Make Huge Impacts on Brain Injury Treatment

Researchers develop a tinier sensor for less invasive intracranial monitoring.

Juan-Pablo Correa-Baena Receives $1M NSF Grant to Study Recycling of Perovskite Solar Cells

Juan-Pablo Correa-Baena Receives $1M NSF Grant to Study Recycling of Perovskite Solar Cells Researchers Find They Can Stop Degradation of Promising Solar Cell Materials

Researchers Find They Can Stop Degradation of Promising Solar Cell Materials Residential Solar Power Saves Less Energy Than Expected

Residential Solar Power Saves Less Energy Than Expected