Smart Hydrogel Coating Creates “Stick-slip” Control of Capillary Action

Jul 25, 2015 — Atlanta, GA

Close-up image shows water from a droplet moving into a narrow glass tube that has been coated on the inside with a hydrogel material. (Credit: John Toon, Georgia Tech)

Coating the inside of glass microtubes with a polymer hydrogel material dramatically alters the way capillary forces draw water into the tiny structures, researchers have found. The discovery could provide a new way to control microfluidic systems, including popular lab-on-a-chip devices.

Capillary action draws water and other liquids into confined spaces such as tubes, straws, wicks and paper towels, and the flow rate can be predicted using a simple hydrodynamic analysis. But a chance observation by researchers at the Georgia Institute of Technology will cause a recalculation of those predictions for conditions in which hydrogel films line the tubes carrying water-based liquids.

“Rather than moving according to conventional expectations, water-based liquids slip to a new location in the tube, get stuck, then slip again – and the process repeats over and over again,” explained Andrei Fedorov, a professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech. “Instead of filling the tube with a rate of liquid penetration that slows with time, the water propagates at a nearly constant speed into the hydrogel-coated capillary. This was very different from what we had expected.”

The findings resulted from research sponsored by the Air Force Office of Scientific Research (AFOSR) through the BIONIC center at Georgia Tech, and were reported earlier this month in the journal Soft Matter.

When the opening of a thin glass tube is exposed to a droplet of water, the liquid begins to flow into the tube, pulled by a combination of surface tension in the liquid and adhesion between the liquid and the walls of the tube. Leading the way is a meniscus, a curved surface of the water at the leading edge of the water column. An ordinary borosilicate glass tube fills by capillary action at a gradually decreasing rate with the speed of meniscus propagation slowing as a square root of time.

But when the inside of a tube is coated with a very thin layer of poly(N-isopropylacrylamide), a so-called “smart” polymer (PNIPAM), everything changes. Water entering a tube coated on the inside with a dry hydrogel film must first wet the film and allow it to swell before it can proceed farther into the tube. The wetting and swelling take place not continuously, but with discrete steps in which the water meniscus first sticks and its motion remains arrested while the polymer layer locally deforms. The meniscus then rapidly slides for a short distance before the process repeats. This “stick-slip” process forces the water to move into the tube in a step-by-step motion.

The flow rate measured by the researchers in the coated tube is three orders of magnitude less than the flow rate in an uncoated tube. A linear equation describes the time dependence of the filling process instead of a classical quadratic equation which describes filling of an uncoated tube.

“Instead of filling the capillary in a hundredth of a second, it might take tens of seconds to fill the same capillary,” said Fedorov. “Though there is some swelling of the hydrogel upon contact with water, the change in the tube diameter is negligible due to the small thickness of the hydrogel layer. This is why we were so surprised when we first observed such a dramatic slow-down of the filing process in our experiments.”

The researchers – who included graduate students James Silva, Drew Loney and Ren Geryak and senior research engineer Peter Kottke – tried the experiment again using glycerol, a liquid that is not absorbed by the hydrogel. With glycerol, the capillary action proceeded through the hydrogel-coated microtube as with an uncoated tube in agreement with conventional theory. After using high-resolution optical visualization to study the meniscus propagation while the polymer swelled, the researchers realized they could put this previously-unknown behavior to good use.

Water absorption by the hydrogels occurs only when the materials remain below a specific transition temperature. When heated above that temperature, the materials no longer absorb water, eliminating the “stick-slip” phenomenon in the microtubes and allowing them to behave like ordinary tubes.

This ability to turn the stick-slip behavior on and off with temperature could provide a new way to control the flow of water-based liquid in microfluidic devices, including labs-on-a-chip. The transition temperature can be controlled by varying the chemical composition of the hydrogel.

“By locally heating or cooling the polymer inside a microfluidic chamber, you can either speed up the filling process or slow it down,” Fedorov said. “The time it takes for the liquid to travel the same distance can be varied up to three orders of magnitude. That would allow precise control of fluid flow on demand using external stimuli to change polymer film behavior.”

The heating or cooling could be done locally with lasers, tiny heaters, or thermoelectric devices placed at specific locations in the microfluidic devices.

That could allow precise timing of reactions in microfluidic devices by controlling the rate of reactant delivery and product removal, or allow a sequence of fast and slow reactions to occur. Another important application could be controlled drug release in which the desired rate of molecule delivery could be dynamically tuned over time to achieve the optimal therapeutic outcome.

In future work, Fedorov and his team hope to learn more about the physics of the hydrogel-modified capillaries and study capillary flow using partially-transparent microtubes. They also want to explore other “smart” polymers which change the flow rate in response to different stimuli, including the changing pH of the liquid, exposure to electromagnetic radiation, or the induction of mechanical stress – all of which can change the properties of a particular hydrogel designed to be responsive to those triggers.

“These experimental and theoretical results provide a new conceptual framework for liquid motion confined by soft, dynamically evolving polymer interfaces in which the system creates an energy barrier to further motion through elasto-capillary deformation, and then lowers the barrier through diffusive softening,” the paper’s authors wrote. “This insight has implications for optimal design of microfluidic and lab-on-a-chip devices based on stimuli-responsive smart polymers.”

In addition to those already mentioned, the research team included Professor Vladimir Tsukruk from the Georgia Tech School of Materials Science and Engineering and Rajesh Naik, Biotechnology Lead and Tech Advisor of the Nanostructured and Biological Materials Branch of the Air Force Research Laboratory (AFRL).

This research was supported by the Air Force Office of Scientific Research BIONIC Center through awards FA9550-09-1-0162 and FA9550-14-1-0269, AFOSR award FA-9550-14-1-0015, and by Georgia Tech’s Renewable Bioproducts Institute Fellowship. The content is solely the responsibility of the authors and does not necessarily represent the official views of the sponsors.

CITATION: J.E. Silva, et al., “Stick-Slip Water Penetration into Capillaries Coated with Swelling Hydrogel,” (Soft Matter, 11, pp. 5933-5939, 2015).

Research News

Georgia Institute of Technology

177 North Avenue

Atlanta, Georgia 30332-0181

Media Relations Contact: John Toon (jtoon@gatech.edu) or (404-894-6986)

Writer: John Toon

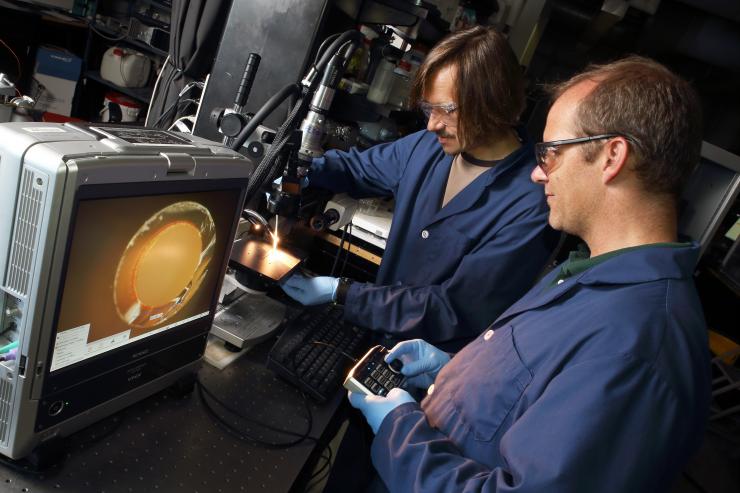

Georgia Tech senior research engineer Peter Kottke adjusts the optics on a study of how hydrogel coatings affect capillary action in a narrow glass tube. (Credit: Candler Hobbs, Georgia Tech)

Georgia Tech professor Andrei Fedorov (left) and senior research engineer Peter Kottke adjust the optics on a study of how hydrogel coatings affect capillary action in a narrow glass tube. (Credit: Candler Hobbs, Georgia Tech)