How Georgia Tech Is Transforming Advanced Manufacturing

Aircraft carriers rely on precision-engineered components to launch and recover planes at sea — a challenge Georgia Tech is helping solve through advanced manufacturing innovation. [Photo courtesy of U.S. Navy]

When the U.S. Navy needed a game-changing repair solution, the Georgia Tech Manufacturing Institute delivered. Now, that same tech is powering innovation across industries.

For decades, the U.S. Navy manually repaired a critical component on its aircraft carriers. The entire Navy relied on a single person to manage these vital fixes, which was untenable for the long haul. The service needed to expand its capabilities for repairing and maintaining wear seals, a key part of the rail system that launches aircraft.

“They identified an opportunity to integrate a more reliable, sustainable process into their repairs,” said Steven Ferguson, principal research scientist and executive director of the Georgia Tech Manufacturing 4.0 Consortium.

“The Navy needed an automated, repeatable solution that could handle a high volume of repairs and rapidly respond to issues.”

The Georgia Tech Manufacturing Institute (GTMI) worked with the Navy to develop a hybrid manufacturing technology that could boost the precision, efficiency, and cost of these repairs and increase the performance of these components on ships. They turned to hybrid repair technology because it offers more capabilities than traditional manufacturing — it can repair damage through machining as well as create high-performance parts.

“With a diverse range of advanced manufacturing technologies, GTMI was uniquely situated to rapidly develop a solution via data-driven hybrid manufacturing,” said Kyle Saleeby, a GTMI research engineer who has spearheaded these projects since 2018.

“Finding innovative solutions to manufacturing challenges is how we’ve advanced manufacturing for decades — and it’s how we’ll continue to shape its future.” —Thomas Kurfess, GTMI

Shaping the Future of Manufacturing

That technology not only transformed the Navy’s repair strategy but also delivered game-changing results across the entire manufacturing ecosystem.

“GTMI has translated the technology developed for the Navy into new capabilities and innovations for numerous transportation, commercial, and industry partners,” noted Ferguson. “We’re constantly evolving this technology to develop solutions for complex manufacturing challenges.”

GTMI has become a key player in advanced manufacturing, translating university research into real-world applications and collaborating with groups such as Delta TechOps, Amsted Rail, and America Makes to strengthen their operations through hybrid manufacturing technology. GTMI also continues to advise the Navy on using manufacturing technology to increase the safety and effectiveness of naval equipment. High-level Navy officials, including the Secretary of the Navy, have visited Georgia Tech to highlight the importance of this strategic partnership.

“Through ongoing collaborations with government and industry leaders, Georgia Tech works at the forefront of manufacturing,” said Thomas Kurfess, GTMI executive director, Regents’ Professor, and HUSCO/Ramirez Distinguished Chair in Fluid Power and Motion Control in the George W. Woodruff School of Mechanical Engineering.

“Finding innovative solutions to manufacturing challenges is how we’ve advanced manufacturing for decades — and it’s how we’ll continue to shape its future.”

Transforming the U.S. Navy’s Repair Strategy

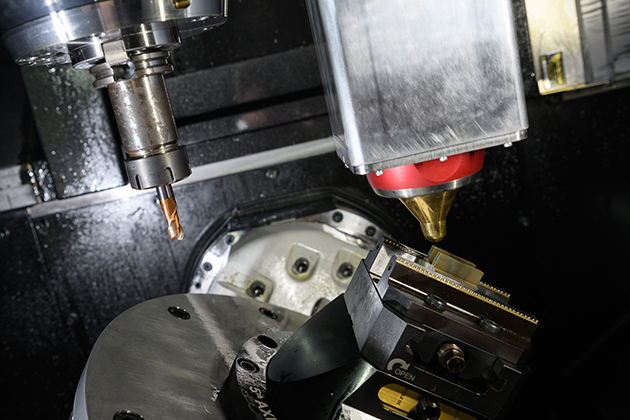

GTMI researchers work beside a Mazak machine inside Georgia Tech’s Advanced Manufacturing Pilot Facility, continuing a partnership with Mazak that has advanced hybrid manufacturing innovation for more than a decade.

When GTMI began working with the Navy, the service wanted to improve the repair strategy for wear seals. These parts are subject to rapid degradation, but the Navy didn’t have a dependable, lasting solution for wear seal maintenance.

GTMI engineers delivered a fast, practical solution by collaborating with the Mazak Corporation, which specializes in cutting-edge machine tools, and OPEN MIND Technologies, a designer of high-tech software. Together, they developed a hybrid manufacturing system that streamlines wear seal maintenance — and even strengthens the components for better performance.

“We realized we could actually improve the wear seal surfaces so they perform better and last longer,” said Saleeby.

Since this initial collaboration, the Navy has expanded the use of metal additive manufacturing across its fleet of ships and other equipment.

“Not only did we solve the original problem, but we also helped them integrate and scale a new manufacturing method to meet national defense needs,” Saleeby added.

“Not only did we solve the original problem, but we also helped them integrate and scale a new manufacturing method to meet national defense needs.” —Kyle Saleeby, GTMI

Advancing Manufacturing Technology Across Industries

Inside a hybrid manufacturing system at Georgia Tech, researchers use additive processes similar to 3D printing to build material and subtractive machining to achieve precision finishes. They combine both methods to create high‑performance components.

The Navy isn’t alone in its need for reliable, efficient, sustainable manufacturing. GTMI has forged key collaborations across government, transportation, and industry to empower numerous partners to enhance their operations through hybrid manufacturing.

“Working with Georgia Tech on hybrid repair research allows us to push the boundaries of what’s possible in advanced manufacturing,” said John Wilczynski, executive director of America Makes. “This effort exemplifies how collaboration accelerates innovation and broadens impact across industries.”

GTMI engineers assess how to translate this technology into new functions so it can make repeatable, reliable repairs for each new manufacturing job — whether wind turbine, railway, or medical part repairs. The researchers examine different components, machining processes, material properties, and possible issues as they apply the manufacturing technology to different uses.

This technology is especially advantageous when it can be used to repair a part instead of sourcing a new one, which can often take months to arrive and come at a high cost.

GTMI’s partners can even benefit from this system during a pandemic: GTMI applied this hybrid repair technology to molds for face masks during Covid-19.

“We can rapidly scale production on this technology so it can be used to respond to national disasters, security events, or public health crises,” explained Saleeby. “We can efficiently respond to anything that affects the manufacturing supply chain, which is a huge need for the country.”

“This effort exemplifies how collaboration accelerates innovation and broadens impact across industries.” —John Wilczynski, America Makes

Innovation at the Speed of Thought

University research doesn’t always have a reputation for efficiency, but GTMI prides itself on “innovating at the speed of thought,” said Kurfess. “We can take a concept and rapidly create a functional prototype. After that, we apply our expertise to scale that prototype into full production. We work at the pace of industry.”

GTMI leadership credits its success to the caliber of its researchers and state-of-the-art facilities, which support rapid prototyping and scalable designs. The Advanced Manufacturing Pilot Facility is especially instrumental, as it gives GTMI researchers an accessible space to collaborate with industrial, academic, and government stakeholders and accelerate projects from idea to reality.

“GTMI’s world-class facilities enable us to develop solutions through public-private partnerships in robust, easy-to-implement ways,” said Ferguson. “We’re working on major problems best solved through teamwork and collaboration — which is exactly what you’ll find at GTMI.”

Writer: Emily Hanlon

Media Contact: Jennifer Martin | jennifer.martin@research.gatech.edu

Photos: Courtesy of the U.S. Navy and Georgia Tech

Copy Editors: Stacy Braukman and Jennifer Martin

Manufacturing Consortium Helps Industry Close the Finish Gap

Manufacturing Consortium Helps Industry Close the Finish Gap  Manufacturing’s Future Is High Tech

Manufacturing’s Future Is High Tech How a Race Car Project Is Transforming Rural STEM Education

How a Race Car Project Is Transforming Rural STEM Education