How a Race Car Project Is Transforming Rural STEM Education

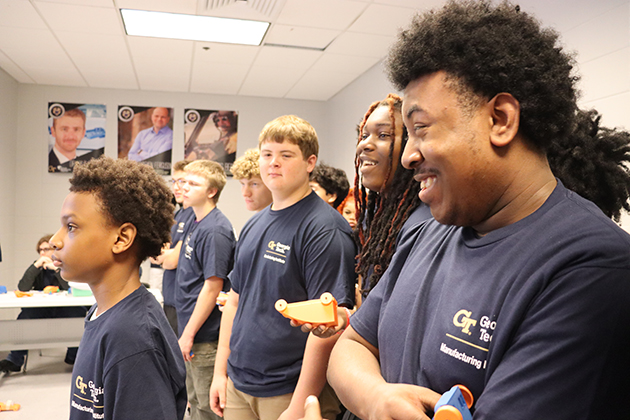

Inside Georgia Tech’s Advanced Manufacturing Pathways program, high school students learn to design, build, test, and dream big through a collaboration that’s reshaping classrooms and communities.

Last fall, the Advanced Manufacturing Pathways (AMP) program served more than 250 students across three school districts.

In a corner of Georgia better known for agriculture than engineering, rural communities are grappling with a familiar challenge: Jobs are growing, but the local talent pipeline is not. As young people leave for opportunities in larger cities, the question facing many employers is no longer whether the jobs exist, but how to prepare students to step into them.

“We’re constantly looking for engineering and technical talent, but we’ve found that you can’t just import talent and expect it to stay in a small town like Thomasville,” says Justin Holland, vice president of Enterprise Optimization at Cleaver‑Brooks, a local manufacturer. Manufacturing has become a major economic force in areas like Thomasville, Georgia, but it's an industry that few students see themselves pursuing. “If we can build their skills up at home in their own community, they might stay.”

As both a Thomasville High School and Georgia Tech alum, Holland has a special connection to a new program emerging from the Georgia Tech Manufacturing Institute (GTMI): the Advanced Manufacturing Pathways (AMP) program. Thomasville is one of three schools participating in AMP, a pilot K–12 initiative designed to bring modern manufacturing tools, techniques, and opportunities directly into rural classrooms.

“Everyone needs manufacturing,” says Kyle Saleeby, GTMI research engineer and one of the lead architects behind the program. “AMP is designed to show students the possibilities within manufacturing.”

“It may be cliche to call something a game changer, but it would be hard to deny that this partnership has changed the game for our students and instructors.” —Amy Zock, Decatur County Schools

Retired U.S. Army officer Lukas Berg (left) joined GTMI in August of 2025 as part of the Hiring Our Heroes program to develop and administer the AMP program.

The program was launched in the fall of 2025 in partnership with the Georgia Tech Research Institute’s Rural Computer Science Initiative. It pairs Georgia Tech expertise with local educators to give students a hands‑on look at modern manufacturing through a project that’s as fun as it is technical: building their own, custom race car. Over the semester, they use digital design tools, 3D printers, machining equipment, and performance data to build pinewood derby‑style cars from scratch. Their work culminates in a race that puts their designs and new skills to the test.

Students at Bainbridge High School in Decatur County, Georgia, were the first cohort to race their creations in October 2025. For Amy Zock, director of Instructional and Innovative Technology at Decatur County Schools, AMP is more than a program — it’s a mindset shift.

“Working with Georgia Tech directly opens our students to the idea that they can be a part of something like Georgia Tech,” she says. “What may have previously seemed unattainable is now tangible. It may be cliche to call something a game-changer, but it would be hard to deny that this partnership has changed the game for our students and instructors.”

Inside the AMP Classroom

Bainbridge High School students in the AMP program gathered in October to race their cars and put their manufacturing skills to the test.

In an AMP classroom, the atmosphere feels less like a traditional high school elective and more like an engineering lab. At any moment, students might be huddled around Computer-Aided Design (CAD) workstations, watching a 3D print, or checking machining tolerances on a freshly milled part. Confidence builds week by week, and what begins as curiosity quickly shifts into genuine technical ownership.

“Many of the students went from almost no knowledge in engineering or CAD design to building their own custom creations,” says Maegan Lenertz, GTMI research engineer and one of AMP’s instructors. “Knowing that we are helping students branch out of their own comfort zones and do something completely new and challenging is such a great feeling.”

From the first day, students dive into digital design, translating their ideas into detailed models and learning how each design decision affects aerodynamics, stability, and performance. As their files are transformed into real parts on the 3D printers, they begin to see the connection between design and production.

“None of this would be possible without the local educators. They are the secret of this program — we’re only empowering them with new tools and resources to increase opportunities for their students.” —Kyle Saleeby, Georgia Tech

A key ingredient of AMP’s success is the collaboration between Georgia Tech instructors and local school leaders who bring advanced manufacturing to life in rural classrooms.

Those digital components are refined as each student machines an aluminum part. For many, it’s their first time operating industrial equipment, but instructors consistently remark on how naturally students adapt. Saleeby, who developed the curriculum for the course, explained that he didn’t have to simplify the technical concepts at all. “High school students are very clever and even more creative. I only changed the scenarios and how the concepts are presented.”

The experience extends beyond fabrication. Throughout the semester, students collect real data on things like temperatures and cycle times from their prints and machining processes. They then use Python to analyze and visualize what’s happening behind the scenes.

By the time they apply open-source AI tools to make race day predictions, they’re thinking like engineers: testing, measuring, optimizing, and adjusting. “So many of them jumped into the course with both feet and went full steam ahead on iterating their designs with only a little bit of experience,” said Lenertz. “It was really awesome to see them figure out how to design for manufacturability.”

Behind the technical experience for students is a support model built intentionally around local educators. Each teacher completes hands-on training at Georgia Tech, working through the custom Python curriculum, learning to operate and troubleshoot the advanced equipment, and becoming comfortable with modern digital design tools. The goal isn’t just to install equipment in rural classrooms, but to ensure that teachers feel equipped to lead.

“None of this would be possible without the local educators,” says Saleeby. “They are the secret of this program. We’re only empowering them with new tools and resources to increase opportunities for their students.”

Students learn how to operate industrial-grade equipment like this 3D printer to manufacture and perfect their designs.

By the time race day arrived for Bainbridge High School, the excitement was palpable. Maegan described one student who spent the morning explaining how the course had “enlightened them to their own strengths” and inspired them to explore college programs they had never considered before. Others, like Bainbridge student Mitchell, talked about discovering entirely new passions.

“I’ve always loved cars,” said Mitchell, who won the People’s Choice Award for his car’s design. “Actually being able to design them on CAD just broadens that passion even more.”

Inside these classrooms, something larger than the construction of race cars is happening. Students are learning to see themselves as designers, problem solvers, and creators — roles that feel newly within reach. As one student put it after seeing his car cross the finish line, the course made him realize “this is a field that I might want to go into after I graduate.”

“One of the biggest benefits of partnering with Georgia Tech on something like this is that it gives our students an ability to see their future story in a way that's broader than what we can show them locally,” says Zock. “This partnership is bigger than just what it does for our kids. It's what it does for our school and our community.”

The AMP program was developed in partnership with STEM@GTRI. It is funded by the Southwest Georgia Regional Commission through funds provided by Georgia Artificial Intelligence in Manufacturing.

Writer: Audra Davidson

Media Contact: Jennifer Martin | jennifer.martin@research.gatech.edu

Video: Christopher McKenney and Bruce Getz

Video Editing: Christopher McKenney

Photos: Courtesy of Bainbridge High School

Copy Editor: Stacy Braukman

Advanced Manufacturing Takes Off in Georgia Classrooms

Advanced Manufacturing Takes Off in Georgia Classrooms  Manufacturing’s Future Is High Tech

Manufacturing’s Future Is High Tech Georgia Tech Taps Military Talent to Boost Manufacturing Workforce

Georgia Tech Taps Military Talent to Boost Manufacturing Workforce