Marine Animals Inspire New Approaches to Structural Topology Optimization

Apr 14, 2021 — Atlanta, GA

A mollusk and shrimp are two unlikely marine animals that are playing a very important role in engineering. The bodies of both animals illustrate how natural features, like the structures of their bones and shells, can be borrowed to enhance the performance of engineered structures and materials, like bridges and airplanes. This phenomenon, known as biomimetics, is helping advance structural topology research, where the microscale features found in natural systems are being mimicked.

In a recent paper published by researchers at the Georgia Institute of Technology and the Pontifical Catholic University of Rio de Janeiro (Brazil), a new approach to structural topology optimization is outlined that unifies both design and manufacturing to create novel microstructures, with potential applications ranging from enhanced facial implants for cranial reconstruction to improved ways to get materials into space for planetary exploration.

“With traditional structural topology optimization, we use algorithms to determine the ideal layout of a structure – one that maximizes structural efficiency and requires fewer material resources,” said Emily Sanders, a Ph.D. student in the School of Civil and Environmental Engineering at Georgia Tech, and co-author of the paper. “Our new research takes that a step further by introducing structural hierarchy, microarchitectures, and spatially-varying mechanical properties to enable different types of functionality like those observed in the cuttlefish and mantis shrimp.”

The properties of both animals inspired the new framework for designing hierarchical, spatially-varying microstructures and required the researchers to build on existing technologies used to create 3D-printed structures.

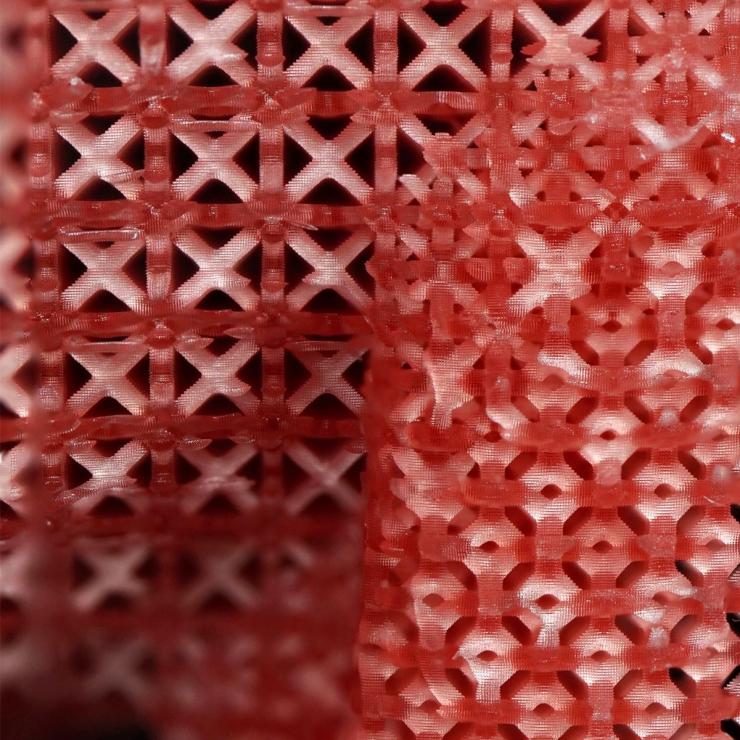

“In our recent work, we’ve developed technology that includes new algorithms and computations that are the enablers of a hierarchical microstructure,” said Glaucio Paulino, Raymond Allen Jones chair and professor in the School of Civil and Environmental Engineering at Georgia Tech, co-author of the paper and recent inductee to the National Academy of Engineering. “We can then input that information into 3D printers and create structures with tremendous amounts of details. After studying the porous, layered cuttlefish bone that has extremely adaptive properties, we’ve been able to apply that to new structures and materials like the ones shown in our paper.”

For Paulino and his team, he hopes this new research will be applied to his earlier work in cranial reconstruction on cancer patients and those who have had massive facial injuries and bone loss.

“Now, we can 3D print craniofacial implants that have been designed using topology optimization and provide the framework for tissue re-growth,” said Paulino. “Ideally when combined with the spatially-varying microarchitectures we’ve recently developed, the implants would more closely mimic the porous nature of the human bone and would promote the growth of the bone itself inside the scaffold. As the bone grows, the scaffold biodegrades, and if everything goes well, in the end the scaffold is gone, and the patient has new bones in the right places.”

Design and Manufacturing

As Sanders explains it, there are two aspects being investigated in this paper that advance the study of topology optimization: design and manufacturing. The first goal is to design an optimal macro geometry and at the same time, optimally distribute spatially-varying micro geometries within, in order to meet performance objectives. In this paper, the researchers were looking for maximally stiff parts with limited volume, much like the mantis shrimp hammer claw and they achieved a high level of complexity that mimics nature at both scales.

The second goal is related to the manufacturing needed to create the structures. With additive manufacturing – or 3D printing – researchers can manufacture structures with complex geometries. But with the research team’s introduction of spatially-varying microstructures, the printing becomes increasingly difficult.

“The more complex 3D data that we would have to send to the printer is so enormous that it’s prohibitive,” said Sanders. “So, we had to find a new way to communicate that information to the printer. Now, we communicate only 2D information, embedding the microstructures directly in 2D slices of the structure. At the end, the printer combines the slices to get the structure. It’s much more efficient.”

“What Emily did with manufacturing closes the loop,” said Paulino. “We deliver on the design, mathematics, and algorithms. And we connect topology optimization with the additive manufacturing at both macro and micro levels.”

Future Applications

When considering the future of the advancements made to structural topology optimization in this paper, Paulino and Sanders both see applications in biomaterials, as well as magnetic properties designed for space exploration.

For Paulino’s work that continues in cranial reconstruction, he envisions interdisciplinary collaborations between engineering, chemistry and biology to develop biocompatible materials and architectures for medical use.

“We’re not there yet, but this work is a step in the right direction,” said Paulino. “Eventually, we’ll be able to print biocompatible materials. This research with spatially-varying microarchitectures should enable the optimal design and manufacturing for biomaterial applications.”

Regarding space exploration, the research could impact the creation of synthetic structures and systems with functionality, like magnetic material assemblages that could be actuated on demand by means of applied magnetic fields.

“An important aspect of this work is that it opened up our design space so that we can have spatially-varying properties, which enables us to do things we couldn’t before,” said Sanders.

Paulino goes on to explain that with space travel, each pound of material sent into space has an enormous cost, so the amount of material and volume brought on space missions is very limited.

“The way I see our manufacturing working in space is you print in place, potentially using printing materials from the foreign planet itself,” said Paulino. “You can bring the additive printing capabilities to Mars and print structures with the properties you need when you get there. You print only what you need versus bringing everything you think you might need. In space, you want everything you do to be optimized.”

Inspired by animals and how they function in nature, Paulino and his team have evolved topology optimization once again, this time with the new design and manufacturing of spatially-varying, hierarchical structures. And, soon, practical applications in biomedicine and space exploration are sure to follow.

---

The research, Optimal and continuous multilattice embedding, was published in Science Advances on April 16, 2021. Along with Glaucio Paulino, coauthors include Emily Sanders (School of Civil and Environmental Engineering) at Georgia Tech, and Anderson Pereira from the Department of Mechanical Engineering at the Pontifical Catholic University of Rio de Janeiro.

This research was supported by the NSF under grant number IIP-1822141 [Phase I I/UCRC at the Georgia Institute of Technology: Center for Science of Heterogeneous Additive Printing of 3DMaterials (SHAP3D)] and from the SHAP3D I/UCRC Members: Boeing Company, U.S. Army CCDC Soldier Center, Desktop Metal, HP Inc., Hutchinson, Integrity Industrial Ink Jet Integration LLC, Raytheon Technologies, Stratasys Ltd., and Triton Systems Inc. E.D.S. and G.H.P. also acknowledge support from the Raymond Allen Jones Chair at the Georgia Institute of Technology, and A.P. acknowledges support from the National Council for Scientific and Technological Development [Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Brazil] under grant 313833/2018-4.

Research News

Georgia Institute of Technology

177 North Avenue

Atlanta, Georgia 30332-0181 USA

Media Relations Contacts: Blair Meeks (wmeeks7@gatech.edu) or Tracey Reeves (tracey.reeves@gatech.edu).

Writer: Georgia Parmelee

Georgia Parmelee

Georgia Tech College of Engineering