Manufacturing Supply Chain and Logistics

An extended enterprise is a network of independent companies with the shared goal of responding to customers with better, less expensive products, processes, and services, faster to market than the competition. A manufacturing supply chain is the flow of goods, information, and money in this network. Supply chains are an integral part of most businesses and are essential to company success and meeting customer demands. They contribute to a firm’s performance by turning raw materials into products and delivering them to the customer at the right time, place, price, and quality. Manufacturing supply chains are focused on balancing cost reduction and risk mitigation in order to improve the financial position and stability of the firm, thereby increasing a company’s competitiveness. Resilience and agile manufacturing supply chains quickly respond to and recover from supply chain disruptions caused by extreme weather, geopolitical issues, pandemics, demand surge, etc. Societally, the manufacturing supply chain helps sustain human life by manufacturing and delivering necessities such as food and water and helps improve human healthcare by delivering pharmaceuticals, personal protective and other medical equipment to healthcare professionals and society more generally. The manufacturing supply chain is a foundation for economic growth that contributes to an improved standard of living, job creation, and a more sustainable, energy efficient environment.

Manufacturing supply chain research currently underway at the Georgia Tech Manufacturing Institute (GTMI) includes:

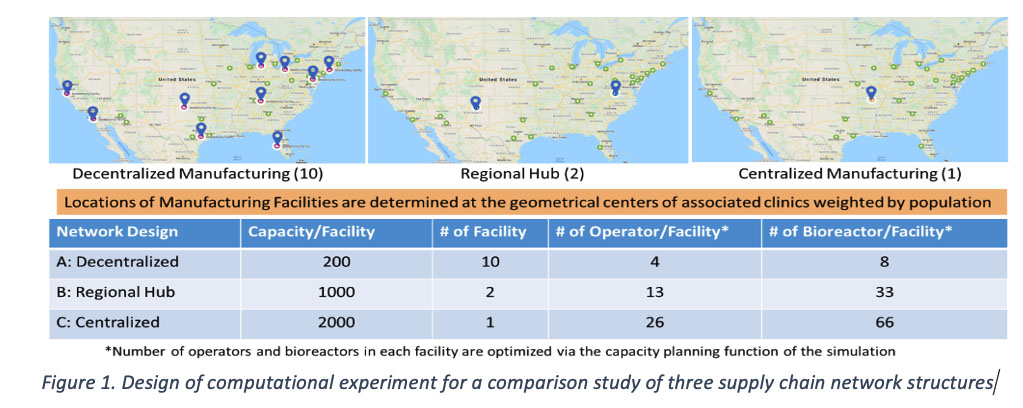

- Developing digital models of a centralized and a distributed manufacturing and distribution network for live human cells and validating the models using production data.

- Developing a capacity planning tool that selects the optimal locations and determines the optimal manufacturing capacities of manufacturing facilities given the geographical distribution of demands and the number of facilities.

- Investigating impacts of reagent supply disruptions and labor shortages on patient access and capacity utilization. CAR-T cell therapies are an exemplar product.

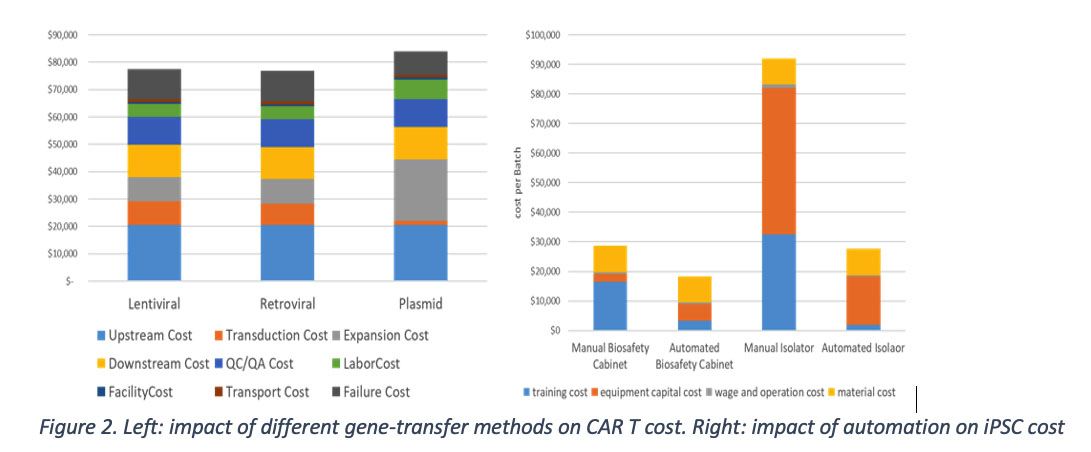

- Developing a hybrid cost-of-goods model, including activity-based costing and parametric costing. Autologous and allogeneic cell therapies were used as the exemplar products. The cost model can be used to assess cost implications and return-on-investment of technological innovations.

GTMI is affiliated with the Georgia Tech Supply Chain and Logistics Institute, the largest supply chain and logistics academic leadership institute in the world and a world leader across a broad range of supply chain and logistics domains.

Faculty and Research Collaborators at GT

- Chris Gaffney, Managing Director, Georgia Tech Supply Chain and Logistics Institute

- Aaron Levine, Ph.D., Associate Professor in the School of Public Policy

- Benoit Montreuil, Coca-Cola Material Handling & Distribution Chair and Professor and Co-Director Supply Chain & Logistics Institute

- Kevin Wang, Ph.D., Research Engineer II, GTMI

- Chip White, Ph.D., Schneider National Chair in Transportation and Logistics and Professor in the H. Milton Stewart School of Industrial and Systems Engineering