Cellular sensing platform supports next-generation bioscience and biotech applications

Apr 29, 2015 — Atlanta, GA

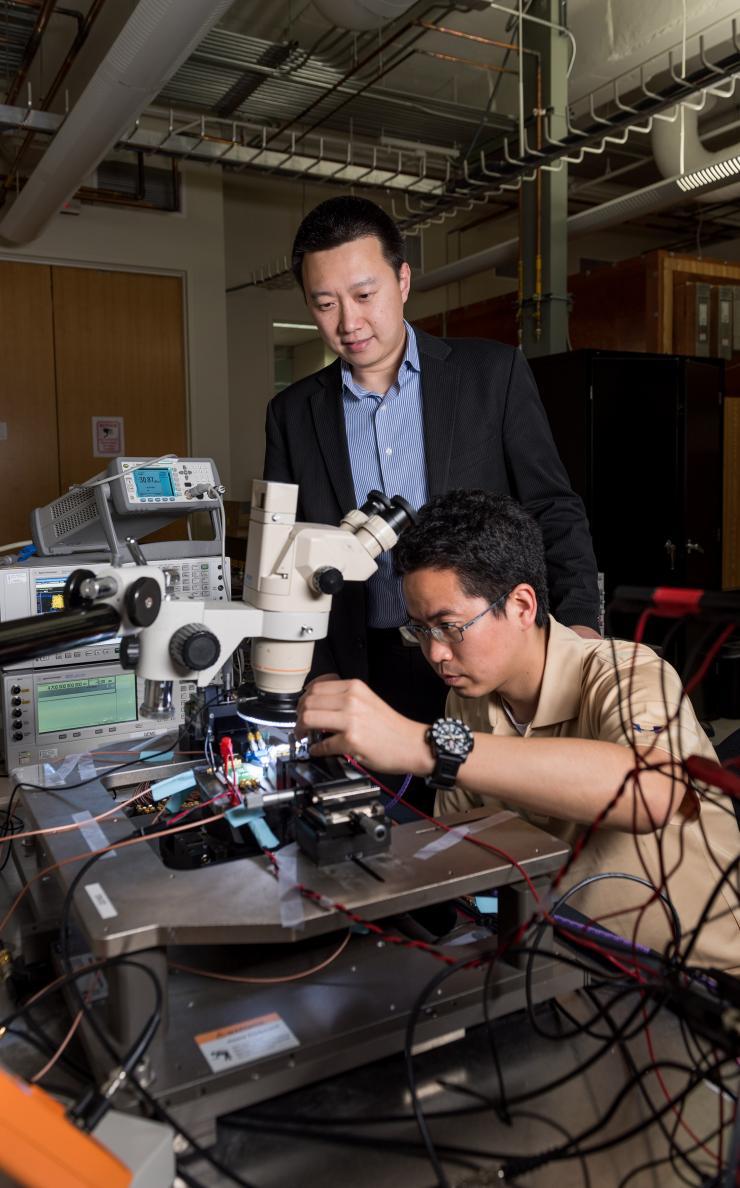

Georgia Tech Ph.D. student Jong Seok Park (right) is performing electrical testing of the CMOS sensor chip with Assistant Professor Hua Wang (left). (Georgia Tech Photo: Rob Felt)

Researchers from the Georgia Institute of Technology have developed a novel cellular sensing platform that promises to expand the use of semiconductor technology in the development of next-generation bioscience and biotech applications.

The research proposes and demonstrates the world’s first multi-modality cellular sensor arranged in a standard low-cost CMOS process. Each sensor pixel can concurrently monitor multiple different physiological parameters of the same cell and tissue samples to achieve holistic and real-time physiological characterizations.

“Our research is intended to fundamentally revolutionize how biologists and bioengineers can interface with living cells and tissues and obtain useful information,” said Hua Wang, an assistant professor in the School of Electrical and Computer Engineering at Georgia Tech. “Fully understanding the physiological behaviors of living cells or tissues is a prerequisite to further advance the frontiers of bioscience and biotechnology.”

The research is part of the Semiconductor Synthetic Biology (SSB) program sponsored and managed by Semiconductor Research Corporation (SRC). Launched in 2013, the SSB program concentrates on synergies between synthetic biology and semiconductor technology that can foster exploratory, multi-disciplinary, longer-term university research leading to novel, breakthrough solutions for a wide range of industries.

Wang said the research can have positive impact on semiconductors being used in the development of health care applications, including the more cost-effective development of pharmaceuticals and point-of-care devices and low-cost home-based diagnostics and drug testing systems. The research could also benefit defense and environmental monitoring applications for low-cost field-deployable sensors for hazard detections.

Specifically, in the case of the more cost-effective development of pharmaceuticals, the increasing cost of new medicine is largely due to the high risks involved in drug development. On average, only one out of every ten thousand tested chemical compounds eventually become an approved drug product.

In the early phases of drug development (when thousands of chemical candidates are screened), in vitro cultured cells and tissues are widely used to identify and quantify the efficacy and potency of drug candidates by recording their cellular physiology responses to the tested compounds.

Moreover, patient-to-patient variations often exist even under the administration of the same type of drugs at the same dosage. If the cell samples are derived from a particular patient, patient-specific drug responses then can be tested, which opens the door to future personalized medicine.

“Therefore, there is a tremendous need for low-cost sensing platforms to perform fast, efficient and massively parallel screening of in vitro cells and tissues, so that the promising chemical candidates can be selected efficiently,” said Wang, who also holds the Demetrius T. Paris Junior Professorship in the School of Electrical and Computer Engineering. “This existing need can be addressed directly by our CMOS multi-modality cellular sensor array research.”

Among the benefits enabled by the CMOS sensor array chips are that they provide built-in computation circuits for in-situ signal processing and sensor fusion on multi-modality sensor data. The chips also eliminate the need of external electronic equipment and allow their use in general biology labs without dedicated electronic or optical setups.

Additionally, thousands of sensor array chips can operate in parallel to achieve high-throughput scanning of chemicals or drug candidates and real-time monitoring of their efficacy and toxicity. Compared with sequential scanning through limited fluorescent scanners, this parallel scanning approach can achieve more than one-thousand times throughput enhancement.

The Georgia Tech research team just wrapped its first year of research under the 3-year project, with the sensor array being demonstrated at the close of 2014 and presented at the IEEE International Solid-State Circuits Conference (ISSCC) in February 2015. In the next year, the team plans to further increase the sensor array pixel density while helping improve packaging solutions compatible with existing drug testing solutions.

“Georgia Tech’s research combines semiconductor integrated circuits and living cells to create an electronics-biology hybrid platform, which has tremendous societal and technological implications that can potentially lead to better and cheaper health care solutions,” said Victor Zhirnov, director of Cross-Disciplinary Research and Special Projects at SRC.

Research News

Georgia Institute of Technology

177 North Avenue

Atlanta, Georgia 30332-0181 USA

Media Contacts: Georgia Tech – John Toon (404-894-6986) (jtoon@gatech.edu) or Semiconductor Research Corporation – Dan Francisco (916-812-8814) (dan@integrityglobal.biz).

Written by Semiconductor Research Corporation.

A CMOS multi-modality cellular sensor array chip being developed at Georgia Tech is hosted on a standard printed circuit board (PCB) and is packaged using low-cost polydimethylsiloxane (PDMS) material to ensure biocompatibility and electrical insulation. A standard 35 mm cell culture dish with drilled-out bottom is mounted on the PCB to host the cells and medium, and expose cells to the CMOS sensing surface. (Georgia Tech Photo: Rob Felt)

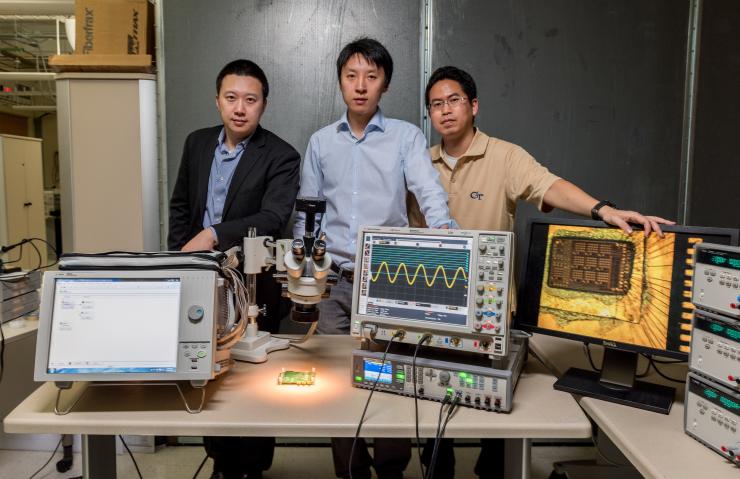

The research team for SRC CMOS multi-modality cellular sensor array project is shown. From left to right: Assistant Professor Hua Wang, Ph.D. Student Taiyun Chi, and Ph.D. Student Jong Seok Park. (Georgia Tech Photo: Rob Felt)

Georgia Tech Assistant Professor Hua Wang is shown in his laboratory. Wang leads a research team developing a novel cellular sensing platform that promises to expand the use of semiconductor technology in the development of next-generation bioscience and biotech applications. (Georgia Tech Photo: Rob Felt).