2026 Sustainability Showcase - Day 2

The Brook Byers Institute for Sustainable Systems holds its signature event each year in the Spring called the Sustainability Showcase. We invite Georgia Tech researchers, students, staff, and partners to share their work with the sustainability community.

2026 Sustainability Showcase - Day 1

The Brook Byers Institute for Sustainable Systems holds its signature event each year in the Spring called the Sustainability Showcase. We invite Georgia Tech researchers, students, staff, and partners to share their work with the sustainability community.

Connecting Communities: Georgia Tech’s Community-Engaged Research Council Drives Engagement and Impact

Dec 04, 2025 —

Grant readiness training participants and facilitators, pictured at the West Atlanta Watershed Alliance's Outdoor Activity Center. Photo includes: Kristin Janacek (BBISS), Thomas Fuentes (Cascade Springs Nature Preserve), Awaz Jabari (Refugee Women's Network), Anurupa Roy (Center for Sustainable Communities), Freddie Stevens III (Re'Gen Community Advisory), Chuck Barlow Sr. (Henderson School Alumni Association and Trust), Katie Kissel (Unearthing Farm and Market), Anna Tinoco Santiago (SCoRE), Tia Davis (ArtsXChange), Cassandra Knight (Henderson School Alumni Association and Trust), Desiree Jones (Georgia Advancing Communities Together), Alexandra Rodriguez Dalmau (SCoRE), Pabitra Poudyel (Refugee Women's Network), Katie O'Connell (Georgia Tech School of City and Regional Planning), Ruthie Yow (SCoRE), and Meena Khodayar (Refugee Women's Network)

Georgia Tech’s research enterprise is expanding its reach beyond campus walls, thanks to the work of the Community-Engaged Research (CER) Council. Formed in 2024, the council focuses on making collaborations between Georgia Tech and community partners easier, more strategic, and more impactful.

“At Georgia Tech, there’s incredible expertise in community engagement,” said Ruthie Yow SCoRE’s associate director, who facilitates the council. “But until now, there was no centralized way to connect those efforts. The council fills that gap.”

Five Pillars for Impact

The council’s strategy centers on five pillars: Coordination, Partners, Faculty Training and Recognition, Communication, and Resource Development. These priorities emerged from a strategic planning process involving seven interdisciplinary research institutes (IRIs) and centers, including Brook Byers Institute for Sustainable Systems (BBISS), Institute for People and Technology (IPaT), Strategic Energy Institute (SEI), Renewable Bioproducts Institute (RBI), the Enterprise Innovation Institute (EI²), Partnership for Inclusive Innovation (PIN) and SCoRE.

New Tool: Community Connect Website

Council members are developing new tools to support these priorities, including the brand-new Community Connect website, led by Nicole Kennard, assistant director for Community-Engaged Research in BBISS. The platform connects faculty and community partners by allowing them to create profiles, post engagement opportunities, and view an interactive map of partnerships.

“When I started this role, faculty told me they wanted to know who Georgia Tech was already working with and how to find new partners,” Kennard said. “They didn’t want to duplicate efforts or cold-call potential partners. This website addresses this challenge by showing existing connections and helping track engagement.”

The site will also serve as a data repository to measure impact of partnerships. “Having this data will help us advocate for infrastructure and support for community-engaged research,” Kennard added.

BBISS, IPaT, and more than 70 people from five of the Institute’s colleges and 18 units across GT supported the development of this new interactive site. The site is up and running while the team makes minor adjustments before a full launch in Spring 2026. Make a profile and share any website feedback with Nicole Kennard.

Building Capacity: Grant Readiness Training

In September, the council sponsored a grant readiness training for 18 community-based organizations. Led by SCoRE, the two-day workshop covered proposal basics, budgeting, logic models, and outcome measurement parameters. Over the course of two full days at the Outdoor Activity Center in West Atlanta, participants in the training helped these partners build the foundational systems, content, and strategies needed for effective grant seeking. Rather than focusing solely on writing techniques, this intensive workshop emphasized organizational readiness—equipping participants with materials such as boilerplate content, budget templates, outcome measurement frameworks, and funder research strategies. Tailored for organizations with limited staff who juggle multiple roles, the training provided practical, immediately applicable tools that support a proactive, long-term approach to securing grant funding. Read more about the training here.

Collaboration in Action: Clarkston Project

Through the leadership of council members Leigh Hopkins and Candice McKie, the council is launching a collaboration with the Center for Economic Development Research (CEDR), to support strategic visioning for the City of Clarkston after funding cuts threatened its planning process. Clarkston, Georgia, one of the most culturally diverse cities in the country, is moving into the second phase of their collaboration with CEDR. The two groups together are continuing to work on place-making, community-wide events, and creative incentives to attract and retain new businesses.

“It was a great example of pooling resources to lift up community vision and meet a community need,” Yow said.

Networking for Impact

On December 10, the council will host a networking event for faculty and staff engaged in CER. The goal is to share successes, attract new collaborators, and identify projects for 2026.

Join us at 2 p.m. in the Student Success Center, President’s Suite B , for light refreshments.

Engagement Across IRIs

Georgia Tech’s interdisciplinary research institutes are already leading impactful projects: IPaT’s CEAR Hub supports climate and cultural resilience in Georgia’s barrier islands; BBISS works on conservation and cultural sustainability with tribal Ojibwe partners; SEI’s Energy Faculty Fellows Program builds research networks with minority-serving institutions; RBI’s ReWood initiative advances renewable forest biotechnology for a climate-smart economy.

Faculty interested in learning more about CER can start by connecting with the council members. “We want to make it easy for researchers and communities to create mutually beneficial partnerships,” Yow said. “Reach out, share your work, and join us in building Georgia Tech’s impact.”

Council members include Terri Sapp (RBI), Clint Zeagler (IPaT), Nicole Kennard (BBISS), Leigh Hopkins and Candice McKie (CEDR), Yang You (SEI), Katie O'Connor (PIN), Ruthie Yow (SCoRE), and Rose Santa Gonzalez (Institute for Robotics & Intelligent Machines.)

Jennifer Martin, Assistant Director of Research Communications Services

Georgia Tech Researchers Among World’s Most Highly Cited in 2025

Dec 02, 2025 —

Georgia Tech proudly announces its faculty who have been named to the Clarivate Highly Cited Researchers 2025 list. This list is a global recognition of scholars with work among the top 1% most cited within their fields. This distinction demonstrates Georgia Tech’s leadership in advancing research with broad and lasting impact.

The Institute’s highly cited researchers include:

- Ian F. Akyildiz - retired professor, Electrical and Computer Engineering

- Antonio Facchetti – professor, Hightower Chair, Materials Science and Engineering

- Maohong Fan – adjunct professor, Civil and Environmental Engineering

- Konstantinos Konstantinidis – professor, Environmental Engineering

- Nian Liu – associate professor and Robert G. Miller Faculty Fellow, Chemical and Biomolecular Engineering

- Anant Madabhushi – professor, Biomedical Engineering

- H. Jerry Qi – Woodruff Professor, Mechanical Engineering

- Rampi Ramprasad – Regents’ Entrepreneur, Materials Science and Engineering

- Rodney J. Weber – professor, Earth and Atmospheric Sciences

- C.P. Wong – Charles Smithgall Institute Endowed Chair and Regents’ Professor, Materials Science and Engineering

“Our faculty’s recognition among the world’s most highly cited demonstrates Georgia Tech’s commitment to pioneering discoveries and solving complex global challenges through research,” said Tim Lieuwen, executive vice president for Research. “Congratulations to each of them on this impressive achievement.”

Clarivate’s annual list identifies researchers whose published work demonstrates exceptional influence, based on citation data from the Web of Science Core Collection over the past 11 years. These scholars have authored multiple Highly Cited Papers, which are publications consistently ranked in the top 1% by citations in their respective fields.

Researchers Develop Biobased Film That Could Replace Traditional Plastic Packaging

Nov 04, 2025 —

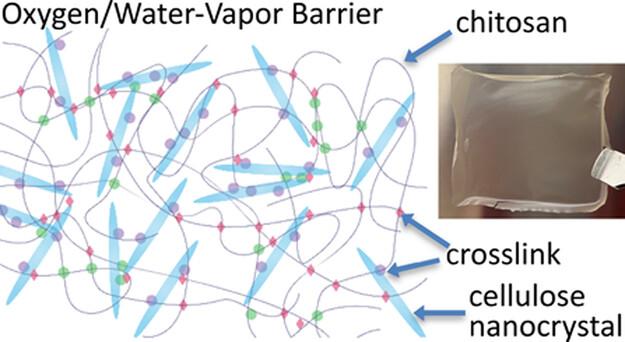

A biologically based film made from natural ingredients found in plants, mushrooms, and food waste

Plastic packaging is ubiquitous in our world, with its waste winding up in landfills and polluting oceans, where it can take centuries to degrade.

To ease this environmental burden, industry has worked to adopt renewable biopolymers in place of traditional plastics. However, developers of sustainable packaging have faced hurdles in blocking out moisture and oxygen, a barrier critical for protecting food, pharmaceuticals, and sensitive electronics.

Now, researchers at the Georgia Institute of Technology have developed a biologically based film made from natural ingredients found in plants, mushrooms, and food waste that can block moisture and oxygen as effectively as conventional plastics. Their findings were recently published in ACS Applied Polymer Materials.

“We’re using materials that are already abundant in nature and degrade there to produce packaging that won’t pollute the environment for hundreds or even thousands of years,” said Carson Meredith, a professor in Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE@GT) and executive director of the Renewable Bioproducts Institute. “Our films, composed of biodegradable components, rival or exceed the performance of conventional plastics in keeping food fresh and safe.”

Meredith’s research team has worked for more than a decade to develop environmentally friendly oxygen and water barriers for packaging. While earlier research using biopolymers showed promise, high humidity continued to weaken the barrier properties.

However, Meredith and his collaborators found a fix using a blend of these natural ingredients: cellulose (which gives plants their structure), chitosan (derived from crustacean-based food waste or mushrooms), and citric acid (from citrus fruits).

“By crosslinking these materials and adding a heat treatment, we created a thin film that reduced both moisture and oxygen transmission, even in hot, humid conditions simulating the tropics,” said lead author Yang Lu, a former postdoctoral researcher in ChBE@GT.

The barrier technology developed by the researchers consists of three primary components: a carbohydrate polymer for structure, a plasticizer to maintain flexibility, and a water-repelling additive to resist moisture. When cast into thin films, these ingredients self-organize at the molecular level to form a dense, ordered structure that resists swelling or softening under high humidity.

Even at 80 percent relative humidity, the films showed extremely low oxygen permeability and water vapor transmission, matching or outperforming common plastics such as poly(ethylene terephthalate) (PET) and poly(ethylene vinyl alcohol) (EVOH).

“Our approach creates barriers that are not only renewable, but also mechanically robust, offering a promising alternative to conventional plastics in packaging applications,” said Natalie Stingelin, professor and chair of Georgia Tech’s School of Materials Science and Engineering (MSE) and a professor in ChBE@GT.

The research team has filed for patent protection for the technology (patent pending). The research was supported by Mars Inc., Georgia Tech’s Renewable Bioproducts Institute, and the U.S. Department of Defense through the National Defense Science and Engineering Graduate Fellowship Program. Eric Klingenberg, a co-author of the study, is an employee of Mars, a manufacturer of packaged foods.

Citation: Yang Lu, Javaz T. Rolle, Tanner Hickman, Yue Ji, Eric Klingenberg, Natalie Stingelin, and Carson Meredith, “Transforming renewable carbohydrate-based polymers into oxygen and moisture-barriers at elevated humidity,” ACS Applied Polymer Materials, 2025.

Professor Carson Meredith

Professor Natalie Stingelin

Brad Dixon, braddixon@gatech.edu

Researchers Discover Spontaneous Chirality in Conjugated Polymers

Oct 16, 2025 —

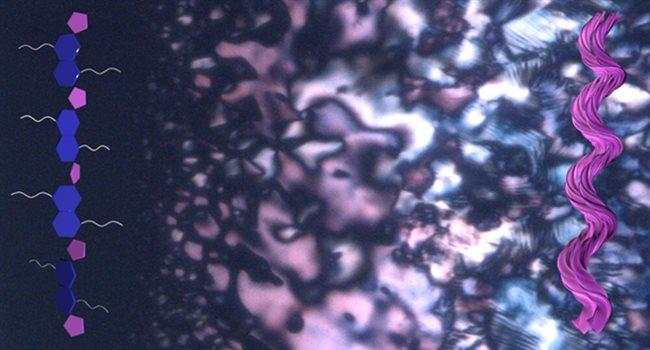

Certain materials can spontaneously form spiral-shaped structures, even when they start out without any 'handedness.' These tiny helices emerge during a phase separation process, offering clues about how life's building blocks may have first developed a preference for one 'handed' form over another. (Credit: Jong-Hoon Lee, Ziming Wang, Ying Diao)

This story by Kristina Shidlauski is shared with the University of Illinois Urbana-Champaign newsroom. John R. Reynolds is a professor in the School of Chemistry and Biochemistry and School of Materials Science and Engineering at Georgia Tech. He served as founder of the Georgia Tech Polymer Network (GTPN) and is a member of the Center for Organic Photonics and Electronics (COPE).

Chirality, a property where structures have a distinct left- or right- “handedness,” allows natural semiconductors to move charge and convert energy with high efficiency by controlling electron spin and the angular momentum of light. A new study has revealed that many conjugated polymers, long considered structurally neutral, can spontaneously twist into chiral shapes. This surprising behavior, overlooked for decades, could pave the way for development of a new class of energy-efficient electronics inspired by nature.

The research, a collaborative project that included researchers from the University of Illinois Urbana-Champaign, Georgia Institute of Technology, University of North Carolina, and Purdue University was recently published in the Journal of the American Chemical Society.

“Many molecules essential to life are chiral,” said Ying Diao, professor of chemical and biomolecular engineering at Illinois, who led the project. “The question that has remained a really a big fascination across the field is how chiral symmetry breaking happens in the first place: that is how life selects one handedness over the other. Our work mainly focuses on the origin of chirality: why chirality spontaneously emerges in absence of any chiral sources.”

To answer this question, the team tested 34 different conjugated polymers. Each polymer was dissolved in a solvent, then the researchers gradually increased the polymer concentration to observe whether liquid–liquid phase separation (LLPS) occurred. When LLPS was detected, they used circular dichroism spectroscopy to analyze the samples, revealing a strong correlation between phase separation and the emergence of chirality. The researchers refer to this phenomenon as spontaneous chiral symmetry breaking.

They found that approximately two-thirds of the polymers spontaneously formed chiral structures when their concentration in the solution increased.

“That took our community by surprise, because conjugated polymers have been studied for half a century,” Diao said. “These new chiral helical states of matter have basically been hiding in plain sight.”

To understand why some of the polymers developed chirality while others did not, Illinois chemistry professor and senior co-author Nicholas E. Jackson applied machine learning to analyze molecular features across the polymer library. The analysis, later backed up by additional testing, revealed that polymers with longer molecular chains were more likely to form chiral assemblies. Unexpectedly, the researchers also found that the presence of oxygen atoms in the side chains was a strong predictor of chiral behavior.

“Machine learning uncovered hidden patterns across dozens of conjugated polymers, relating subtle chemical details to chiral phase formation,” Jackson said. “Such insights would have been very difficult to derive by human intuition alone.”

Diao noted that the discovery not only deepens our fundamental understanding of chiral emergence but also holds significant technological promise. In nature, chiral systems – such as those involved in photosynthesis – enable highly efficient electron transport. Looking ahead, Diao said that mimicking this behavior could lead to major performance gains in electronic devices and innovation of new device types.

“We are thinking about using chirality to control conductivity – for example, in transparent conductors for phones or in solar cells that could be more stable and efficient,” she said. “In our computers, electrons bounce around and heat is a big problem. But if we make chiral versions, we think charge transfer could be extremely efficient, just like in nature.”

“What’s nice about this is, this is not the end of the story,” said Georgia Institute of Technology chemistry professor John Reynolds, a senior co-author on the study. “This work provides guidance to polymer scientists in the field for studying the many, many conjugated polymers that have been synthesized over the years, and for designing new polymers with enhanced properties.”

This study was supported by the U.S. Office of Naval Research, the Air Force Office of Scientific Research, the Molecule Maker Lab Institute, and the National Science Foundation. Polymers for the study were provided by Reynolds, University of North Carolina chemistry professor Wei You, University of Illinois chemistry professor Jeff Moore, and Purdue University chemistry professor Jianguo Mei.

In addition to her appointment in Chemical & Biomolecular Engineering, Diao is a full-time faculty member at the Beckman Institute for Advanced Science and Technology, holds a faculty appointment with Chemistry in the College of Liberal Arts & Sciences, and is affiliated with Materials Science & Engineering in The Grainger College of Engineering. In addition to his appointment in Chemistry, Jackson is a group leader at the Beckman Institute and affiliate faculty member in the departments of Chemical & Biomolecular Engineering and Materials Science & Engineering.

The paper, "Ubiquitous Chiral Symmetry Breaking of Conjugated Polymers via Liquid Liquid Phase Separation," is available online at https://pubs.acs.org/doi/abs/10.1021/jacs.5c07995

Jess Hunt-Ralston

Director of Communications

College of Sciences at Georgia Tech

To reach Ying Diao: yingdiao@illinois.edu

BBISS Announces 2025 Sustainability Next Seed Grant Recipients

Oct 07, 2025 —

The 2025 round of Sustainability Next Research Seed Grants has been awarded to 17 transdisciplinary research teams representing a vibrant network of 51 collaborators from across Georgia Tech. These teams span 21 unique units from six of the seven Colleges, including Schools, research centers, and Interdisciplinary Research Institutes.

The seed grant program, administered by the Brook Byers Institute for Sustainable Systems (BBISS), reaches many faculty members from a diverse array of disciplines due to the generous support provided by broad-based partnerships in addition to the Sustainability Next funds. This year’s partners are the Georgia Tech Arts Initiative, BBISS, Walter H. Coulter Department of Biomedical Engineering, School of Civil and Environmental Engineering, College of Design, School of City and Regional Planning, School of Computer Science, Ray C. Anderson Center for Sustainable Business, Energy Policy and Innovation Center, Parker H. Petit Institute for Bioengineering and Bioscience, Institute for Matter and Systems, Institute for People and Technology, Institute for Robotics and Intelligent Machines, Strategic Energy Institute, and Center for Sustainable Communities Research and Education.

The goal of the program is to nurture promising research areas for future large-scale collaborative sustainability research, research translation, and/or high-impact outreach; to provide mid-career faculty with leadership and community-building opportunities; and to broaden and strengthen the Georgia Tech sustainability community as a whole. The call for proposals was modeled after the Office of the Executive Vice President for Research’s Moving Teams Forward and Forming Teams programs.

Looking ahead, BBISS will support and nurture these projects in collaboration with the relevant funding partners. Beginning in October, BBISS will host a series of focused workshops designed to foster collaboration and provide additional support to help advance these initiatives. Projects have been grouped into five thematic clusters, each of which will be the focus of an upcoming workshop:

- Circularity Programs

- Adaptation to the Changing Environment

- Community Engagement and Education

- Climate Science and Solutions

- Environmental and Health Impacts

BBISS faculty fellows, past seed grant recipients, and other interested Georgia Tech faculty are invited to participate. If you are interested in participating in the workshops, please email kristin.janacek@gatech.edu. The first session on Circularity Programs is Oct. 16 at 1 p.m. in the Peachtree Room (3rd floor) of the John Lewis Student Center.

The 2025 Sustainability Next Seed Grant awards are:

Forming Teams:

- Developing a Sustainable and Ethical Electric Vehicle Ecosystem Workforce for the Future Through Cross-Sector Partnerships. Principal Investigators (PI): Joe Bozeman. Co-Principal Investigator (Co-PI): Jennifer Hirsch.

- Unlocking Circularity at Scale: Platform-Based Solutions for Advancing Material Reuse and Supply Chain Resilience. Principal Investigator: Marco Ceccagnoli. Co-PIs: Matthew Realff, Patricia Stathatou, Christos Athanasiou.

- OpenGUARD: Geospatial Utility Aggregations with Robust Differential Privacy. PI: Patrick Kastner. Co-PI: Juba Ziani.

- Regenerative Framework: A Transdisciplinary Model for Urban Climate Resilience and Soil Health. PI: Jenny McGuire. Co-PI: Nicole Kennard.

- Guiding Transportation With Community Action Through Research, Education, and Service (GT-CARES). PI: Rounaq Basu. Co-PIs: Ruthie Yow, Sofía Pérez-Guzmán, Rebecca Watts Hull.

- Co-optimizing Design and Coordination for Sustainable Multi-Robot Construction. PI: Edvard Bruun. Co-PI: Harish Ravichanda.

- Campus as Material Ecology: Building Transdisciplinary Circular Systems for Plastic Tracking, Transformation, and Community Engagement. PI: Hyojin Kwon. Co-PIs: Michael Best, Russ Clark, Tim Trent, Meisha Shofner.

- Sonifying Climate Infrastructures: Community Outreach and Education With Shade Synthesizer. PI: Heidi Biggs. Co-PIs: Clint Zeagler, Alexandria Smith.

- Building a Georgia Tech Research Partnership for Community-Based Food System Resilience. PI: Johannes Milz. Co-PIs: Xin Chen, Inge Rocker, Sofía Pérez-Guzmán, Nicole Kennard.

Moving Teams Forward:

- Are Data Centers the New Landfills? Social, Economic, and Environmental Tradeoffs. PI: Allen Hyde. Co-PIs: Josiah Hester, Cindy Lin, Nicole Kennard, Joe Bozeman, Elora Raymond, Tony Harding, Jung-Ho Lewe.

- Game-Based Learning in Energy Systems: A Rigorous Evaluation of Current Crisis. PI: Jessica Roberts. Co-PI: Daniel Molzahn.

- Strategic Application of Antibiotic-Independent Therapy to Treat Coral Disease Outbreaks. PI: Lauren Speare.

- Advancing Water Reuse Through Research, Education, and Community Partnerships in Atlanta, Georgia. PI: Katherine Graham. Co-PIs: Amanda Nolen, Yeqing Kong.

- Assessing the Accuracy and Reliability of Low-Cost Particulate Matter (PM) Sensors Across Diverse Ambient Environments. PI: Nga Lee (Sally) Ng. Co-PI: Ted Russell.

- Developing a Georgia Community Center Into a Sustainability Hub. PI: Ashutosh Dhekne, Co-PIs: Umakishore Ramachandran, Danielle Willkens, Ruthie Yow.

- What, When, Where of Air Pollution: PM2.5 and How It Impacts Health. PI: Shuichi Takayama. Co-PI: Nga Lee (Sally) Ng.

- Enabling Communities to Baseline the Performance of Energy Systems. PI: Jung-Ho Lewe. Co-PIs: Scott Duncan, David Solano Sarmiento, Danielle Willkens, Anna Tinoco-Santiago.

This round of funding was highly competitive, with 45 proposals submitted. BBISS extends its gratitude to all the individuals and groups who applied, as well as to the faculty and staff who contributed their time and expertise to evaluate the proposals. Their thoughtful input was essential to achieving a fair and collaborative selection process, ensuring that the awarded proposals align strongly with the BBISS’ strategy and show promise for long-term impact and future research opportunities.

According to BBISS Executive Director Beril Toktay, and Brady Family Chair in Management, “The high level of participation demonstrates the enduring commitment to sustainability research and engagement by the Georgia Tech community. BBISS honors this commitment by looking for collaboration opportunities with all who are driving sustainability efforts at Georgia Tech.”

Brent Verrill, Research Communications Program Manager, BBISS

Atlanta Science Festival Kickoff at Georgia Tech | Celebrate STEAM

Georgia Tech is excited to kickoff off the 13th annual Atlanta Science Festival by welcoming the community to our campus to Celebrate STEAM! Attendees can participate in hands-on STEAM activities, watch science and technology demonstrations, connect with student researchers, and discover the exciting advancements happening at Georgia Tech. The event is free and we have something for everyone with robotics, brains, biology, space, art, nanotechnology, paper, computer science, wearables, bioengineering, chemical engineering, or systems engineering.

BBISS Insights Series - 11/20

We look forward to hosting you at three upcoming events. The BBISS Insight Series aims to address the evolving needs of the BBISS community through in-person and virtual events to help GT researchers amplify their impact in sustainability research.

For the fall semester, the series will feature speakers with experience engaging government agencies for partnerships and proposal development. These sessions are designed to help researchers identify research opportunities and partners to build an impactful research program.

BBISS Insights Series - 10/30

We look forward to hosting you at three upcoming events. The BBISS Insight Series aims to address the evolving needs of the BBISS community through in-person and virtual events to help GT researchers amplify their impact in sustainability research.

For the fall semester, the series will feature speakers with experience engaging government agencies for partnerships and proposal development. These sessions are designed to help researchers identify research opportunities and partners to build an impactful research program.