Meredith Receives AIChE’s Andrew Chase Award

Oct 23, 2024 — Atlanta, GA

J. Carson Meredith, Executive Director of the Renewable Bioproducts Institute and Professor in Georgia Tech's School of Chemical and Biomolecular Engineering.

J. Carson Meredith, Executive Director of the Renewable Bioproducts Institute (RBI) and professor in Georgia Tech’s School of Chemical and Biomolecular Engineering, is the 2024 recipient of the Andrew Chase Award from the American Institute of Chemical Engineers (AIChE) Forest and Plant Bioproducts Division. He will receive the award at the Annual AIChE Meeting in San Diego California, later this month.

The award recognizes Meredith’s research in nanocellulose chemical modification, composites, and cellulose-based renewable barrier coatings, which has resulted in seven patent applications, one commercial license, and ongoing research projects with six companies, reflecting the impact these advancements are making. His group recently reported the first successful recycling and reuse of nanocellulose gas barrier films and achieved one of the lowest water vapor barrier coatings derived from cellulose to date.

The Chase Award also recognizes Meredith’s leadership role, in restructuring RBI to be more inclusive of other disciplines, more focused on key impact areas in defossilization through bioproducts and the emerging bioeconomy.

For example, RBI has made investments in space and helped to secure funding and other resources for more than 70 Georgia Tech faculty, including the addition of 23 new faculty not previously supported by RBI. These include five new schools across the College of Engineering, College of Sciences, and Ivan Allen College of Liberal Arts. "This interdisciplinarity is crucial to the role of chemical engineering within the broader bioeconomy space," Meredith said.

Brad Dixon || braddixon@gatech.edu

Georgia Tech Scientist Boosts Forestry Industry With Cutting-Edge Tree Cloning

Oct 10, 2024 — Atlanta, GA

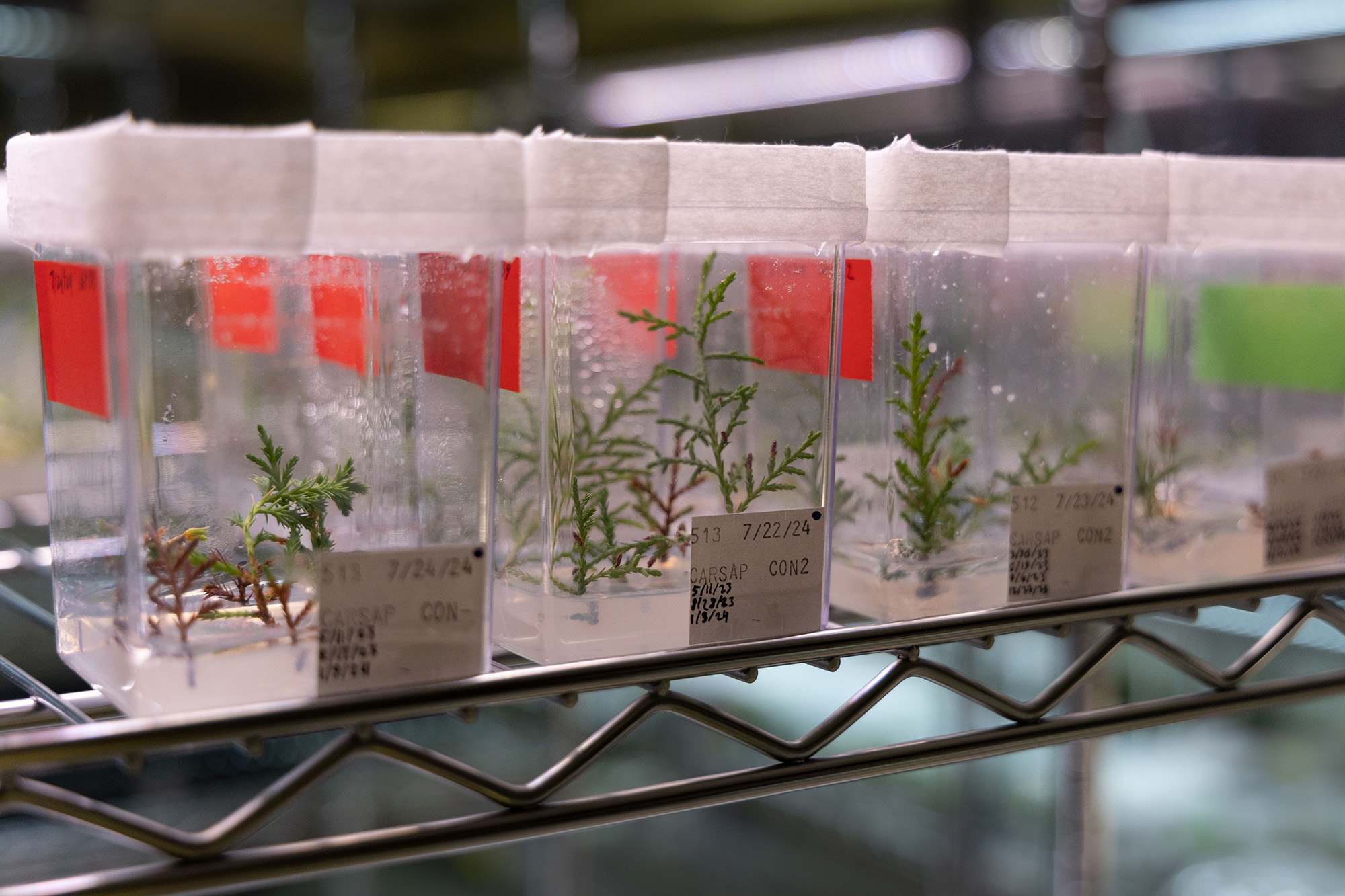

Ulrika Egertsdotter, a principal research scientist at the Renewable Bioproducts Institute and a renowned expert in seed cloning, designs and develops automated technologies that produce valuable plants for the state’s forestry, agriculture, and horticulture industries. (Credit: Chris McKenney)

Georgia’s forestry industry generates $40 billion annually, providing 140,000 jobs. The state is known for its timber, fiber, paper pulp, and other wood-derived products, which are exported worldwide.

Ulrika Egertsdotter, a principal research scientist at Georgia Tech’s Renewable Bioproducts Institute, plays a key role in supporting the industry. Through her work, she helps Georgia tree growers propagate new plants that provide higher-quality wood products and offer greater resilience to climate change.

“Some say we shouldn't interfere with nature, but humans are demanding more and more from the Earth, faster than it can provide,” Egertsdotter said. “We need to help nature produce at a sustainable rate and quality necessary for human requirements.”

Her primary research involves applying new technologies and automation to produce improved conifer trees, which include spruce, cedar, and — most notably in Georgia — pine. These needle-bearing trees are some of the most important globally for providing wood and fiber.

Plant breeders want to reproduce trees or plants with excellent traits — for example, those that can grow in dry environments or resist fungal attacks. Developing a robust plant that meets these requirements can take decades, particularly with trees, which need many years to grow.

That’s where Egertsdotter’s work comes in. Scientific advancements have enabled researchers to design new plants, including trees that yield better wood products or are more resilient against extreme weather conditions such as drought. Producing enough of these special, superior plants requires efficient cloning techniques — otherwise, it would take years or even generations.

Cloning plants in vitro, or micropropagation, is exponentially faster than traditional cloning by cuttings and helps growers produce more trees and harvest high-quality timber on shorter timelines. For conifers, the favored micropropagation method is to clone the seeds by a technique called somatic embryogenesis (SE), which is the basis for making new and better conifer trees using biotechnological methods.

“In the lab, with one plant seed, we can make millions of plants from that same seed,” Egertsdotter said.

Cloning Trees in the Lab

Cloning conifers like pines always starts with picking seeds from the cone. Then, in a sterile lab environment, researchers clean a single seed and extract an embryo from inside it. They place the embryo in a small dish with nutrients and plant-growth regulators that stimulate the embryo to form new embryos.

By repeatedly feeding the culture with the same treatments, the new embryos will continue to multiply into identical copies of the initial seed. Once the number of embryos has increased significantly, the researchers split them up into new plates. When, finally, many embryos have developed, other treatments are applied to make the embryos mature and eventually germinate into a new plant.

“The biological process the lab (somatic) embryo goes through to form the plant is the same biological process a seed embryo would go through if it was planted in the ground,” Egertsdotter explained. “This method allows us to generate many plants from each valuable seed, instead of just one.”

Automated Technologies

While micropropagation methods have been around for decades, they are expensive and labor-intensive and are not widely used outside of research labs. Egertsdotter works closely with engineers to develop and implement novel automation technologies that can produce affordable, high-quality plants through a system based on fluidics technology, image analysis, and AI-based selection.

The SE Fluidics System is a unique facility developed at Georgia Tech for the fast processing of somatic embryos of any species. The system carries out rapid imaging of each embryo and then produces datasets to develop algorithms that select viable embryos for further processing.

In addition to cloning selected plants from breeding programs, SE can also be used to add desired characteristics to trees and plants. Researchers have also started experimenting with the gene-editing tool CRISPR to modify the DNA sequences of some tree species.

Moving Forward

Because of human-caused climate change, the natural habitats of many important plants and crops have already been permanently altered or destroyed. For Egertsdotter, this adds urgency to her work.

She is currently investigating how to develop pine trees more resistant to climate-related stresses, including pests and drought. Egertsdotter is also studying how to use biotechnological tools to create trees that capture carbon dioxide more efficiently.

“We must support the plants we rely on by multiplying the specific plants that can survive in the future environment,” Egertsdotter said. “We can also help other plants survive by genetic or genomic modifications to increase their adaptability.”

She added, “We will lose a lot of the natural resources we currently rely on if we wait for nature to, through natural selection, correct the negative impact of climate change. We are changing the natural world faster than evolution can keep up, so we must help accelerate the adaptation process.”

The team uses bioreactors for fast multiplication of young plants or maturation of somatic embryos which will later be harvested. Feeding is controlled electronically through a solenoid valve. (Credit: Chris McKenney)

Postdoctoral fellow Cuong Le holds pecan tree shoots used to start in vitro cultures while researchers work to maintain established in vitro cultures under sterile conditions. Pecan trees in Georgia are susceptible to pests and natural disasters, and Egertsdotter's team works to produce more resilient pecan plants. (Credit: Chris McKenney)

Egertsdotter and faculty from the School of Mechanical Engineering developed the SE Fluidics System (pictured). It is a unique facility at Georgia Tech designed for fast processing of somatic embryos of any species. The system carries out rapid imaging of each embryo and then produces datasets to develop algorithms (including machine learning) to select viable embryos for further development into plants. (Credit: Chris McKenney)

Shannon Johnson, research scientist III in the School of Mechanical Engineering, examines a young plant while working with the SE Fluidics System. (Credit: Chris McKenney)

Baby conifer seedlings from elite plant lines that have been cultivated in Egertsdotter's lab. (Credit: Chris McKenney)

Catherine Barzler, Senior Research Writer/Editor

Innovation at Scale: Georgia Tech Unveils New Roll-to-Roll Manufacturing Pilot Facility

Oct 03, 2024 —

Partners of the facility gathered for an official ribbon cutting ceremony. From left to right: Eric Vogel, Hightower Professor in MSE and executive director for the Institute for Matter and Systems; Devesh Ranjan, Eugene C. Gwaltney, Jr. school chair and professor in the George W. Woodruff School of Mechanical Engineering; Julia Kubanek, vice president of Interdisciplinary Research; Tequila Harris, professor in the Woodruff School and facility leader; Christine Conwell, interim executive director for the Strategic Energy Institute; Tim Liewen, interim executive vice president for Research; Thomas Kurfess, Regent's Professor in the Woodruff School and executive director of the Georgia Tech Manufacturing Institute; J. Carson Meredith, professor and James Preston Harris Faculty Fellow in the School of Chemical and Biomolecular Engineering, executive director of the Renewable Bioproducts Institute. Photo: Christopher McKenney.

Whether it’s developing new products, reducing costs, or increasing accessibility, innovations in manufacturing stand to improve the lives of companies and consumers alike. Georgia Tech recently took another step toward ensuring those innovations make it from lab to market with the launch of a Modular Pilot Scale Roll-to-Roll Manufacturing Facility.

“As researchers develop new materials, one of the key aspects we’re missing is how to make them at scale. This is a major oversight because if we can’t make them at scale, we can’t transition from basic research to commercialization,” said Tequila Harris, a professor in the George W. Woodruff School of Mechanical Engineering. “With this new facility, we can prove our discoveries beyond lab-scale studies — and can go from materials innovation to product development at scale.”

Led by Harris, the new facility is the result of a partnership between the Georgia Tech Manufacturing Institute (GTMI), the Strategic Energy Institute, and the Woodruff School. As a pilot facility, it will serve as a testbed for scaling up manufacturing research open for Georgia Tech researchers as well as academic, government, and industry partners around the world.

“The larger vision I see at Georgia Tech involves innovation in manufacturing for large-scale industries,” said Georgia Tech’s Interim Executive Vice President for Research Tim Lieuwen at the facility’s unveiling event on Sept. 19. “It’s crucial that we’re innovating in basic science and technology, but we also need to be innovating in large-scale manufacturing.”

Roll-to-roll (R2R) manufacturing transforms flexible rolls of substrate materials, such as paper, metal foils, and plastics, into more complex, transportable rolls upon coating the surface with one or more fluids, such as inks, suspensions, and solutions, which are subsequently dried or cured on the base substrate. Its high yield and efficiency make R2R an ideal method for the sustainable, large-scale production of components for solar cells, batteries, flexible electronics, and separations — all industries that have expanded in Georgia in recent years.

“As a state institution, we’re ultimately here to serve our state,” said Lieuwen, who is also Regents’ Professor and David S. Lewis Jr. Chair in the Daniel Guggenheim School of Aerospace Engineering. “We’re seeing Georgia emerge as the national leader in terms of recruiting corporate investments in this space and in industries that will be served by this facility.”

Roll-to-Roll Innovations

The R2R process is similar to the production of newspapers, where a large roll of blank paper goes through a series of rollers printing text and photos. “The roll-to-roll aspect is the process of using a specialized tool to force fluid onto a moving surface,” says Harris. It’s one of the fastest-growing methods for producing thin film materials — photovoltaics used in solar cells, transistors in flexible electronics, and micro-batteries, for example — at a large scale.

Harris’s group works to develop novel manufacturing tools, with a particular focus on understanding and improving the dynamics of thin film manufacturing to increase efficiency and minimize waste. Her group is particularly interested in slot die coating, an R2R technique where a liquid material is precisely deposited onto a substrate through a narrow slot. With the new pilot facility, researchers like Harris will be able to take their work to the next level.

“Slot die coating on a roll-to-roll can handle the broadest viscosity range of most coating methods. Therefore, you can process a lot of different materials very quickly and easily,” says Harris. “It’s one of the fastest-growing technologies in the U.S. — and currently, this is the most advanced modular pilot scale facility at an academic university in the United States.”

“Georgia Tech is way ahead of the curve in terms of our facilities,” says GTMI Executive Director and Regents’ Professor Thomas Kurfess. “This will grow our capability in the battery area, membranes, flexible electronics, and more to allow us to support the development of new technologies.”

“As technologies around cleantech continue to advance at an unprecedented pace, pilot manufacturing facilities provide a critical bridge between innovative benchtop research and commercial-scale production and manufacturing,” says Christine Conwell, interim executive director of the Strategic Energy Institute. “We are excited about the opportunities this R2R facility will provide to the Georgia Tech energy community and our industry partners.”

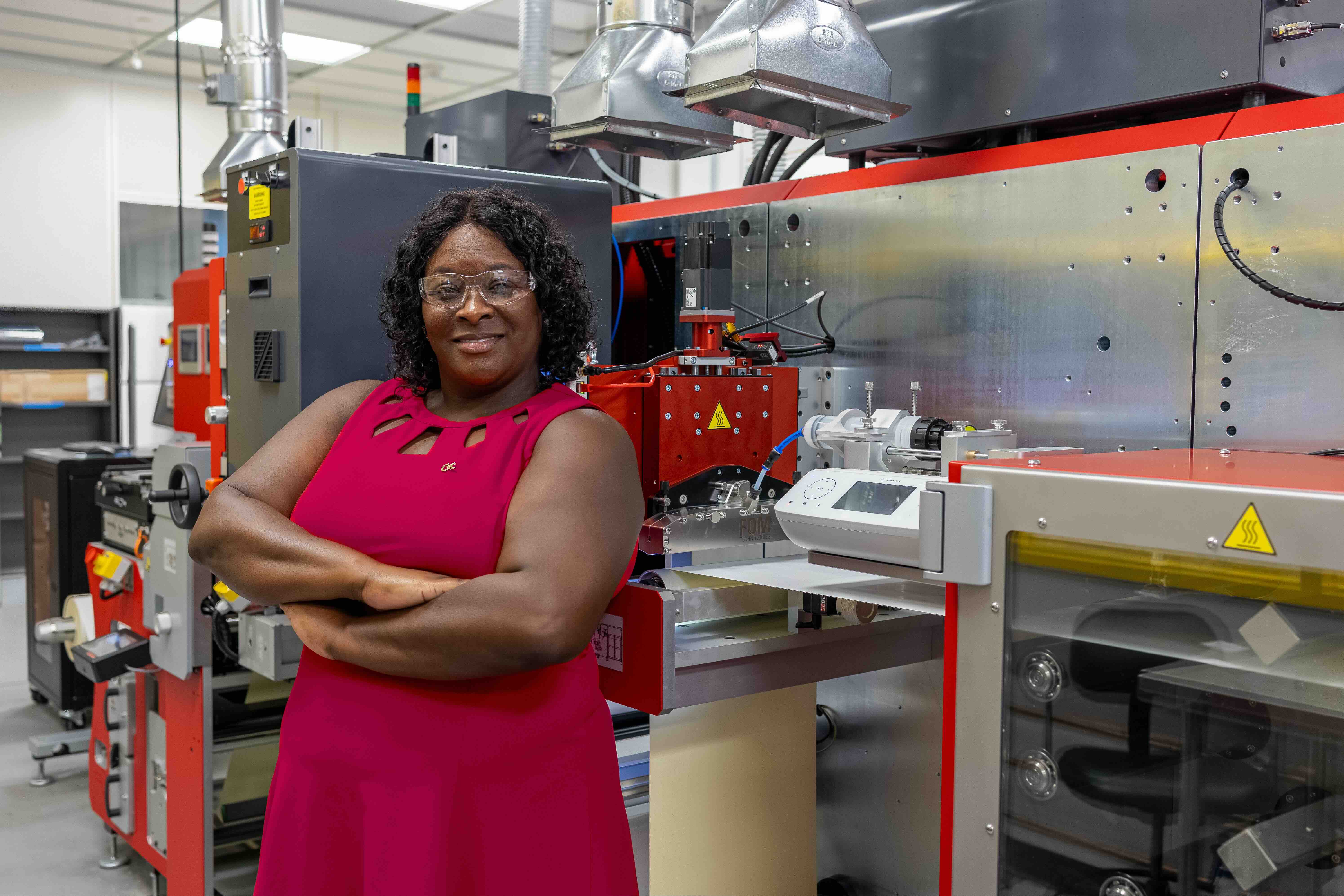

Tequila Harris, professor in the George W. Woodruff School of Mechanical Engineering, next to the modular R2R equipment. Photo: Christopher McKenney.

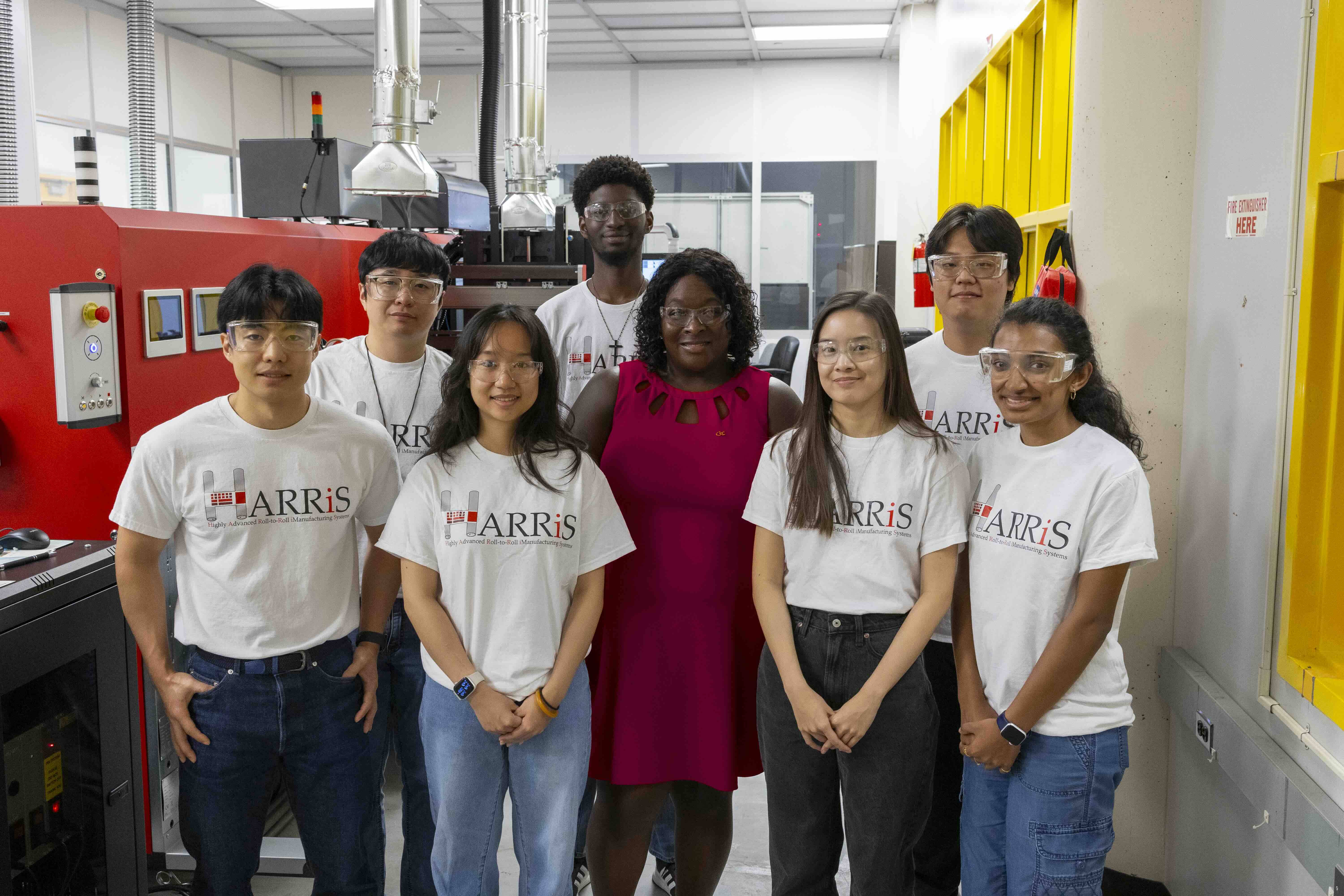

The Highly Advanced Roll-to-Roll iManufacturing Systems (HARRiS) research group in the new R2R facility. Photo: Christopher McKenney.

Audra Davidson

Research Communications Program Manager

Georgia Tech Manufacturing Institute

BBISS Executive Director Search

Oct 01, 2024 —

Please visit this page for up-to-date information about the progress of this search.

The Georgia Institute of Technology (Georgia Tech) invites applications and nominations for the Executive Director (ED) position in the Brook Byers Institute for Sustainable Systems (BBISS). BBISS, one of Georgia Tech’s Interdisciplinary Research Institutes (IRIs), brings together researchers from across Georgia Tech, including academic and research units, to support world-class sustainability-focused research, student engagement, and industry, government, and nonprofit collaboration toward achieving systemic change.

The BBISS ED will be a dynamic, collaborative, and entrepreneurial leader who will unite a broad range of stakeholders around a vision to elevate and grow sustainability at Georgia Tech. As a systems thinker and inclusive relationship builder, the ED will expand and enhance BBISS collaborations and partnerships within and beyond Georgia Tech to broaden its sustainability footprint in local, regional, national, and international arenas.

The ED will catalyze the formation of interdisciplinary teams to support high-impact programming and grants in areas such as climate science, solutions, and policy; ecosystem and environmental health; sustainable cities and infrastructure; sustainable resource and material use; just and equitable sustainable development; and the economics and business of sustainability.

Applications, Inquiries, and Nominations

To apply for the Executive Director position in the Brook Byers Institute for Sustainable Systems, candidates are requested to submit the following:

- A curriculum vitae

- A letter of interest (not to exceed four pages) that summarizes your qualifications and includes a brief statement of your vision for BBISS

- Contact information for five references (to be contacted with candidate’s permission at a later date)

Candidates are requested to send their application materials (in Word or PDF) to the AGB Search Portal at this link by November 19, 2024, for best consideration.

Nominations and expressions of interest for this opportunity are encouraged. Please direct them to BBISSGATech@agbsearch.com or to the AGB search consultants listed below.

Monica Burton, Principal

monica.burton@agbsearch.com

C: 917.825.2961

Nancy Targett, Ph.D., Executive Search Consultant

nancy.targett@agbsearch.com

C: 302.233.5202

Brent Verrill, Research Communications Program Director, BBISS

Scheller Business Insights: Achieving Net Zero Featuring Beril Toktay

Sep 25, 2024 — Atlanta, GA

Scheller Business Insights is a dynamic video series that highlights the innovative thought leadership of the esteemed faculty at the Georgia Tech Scheller College of Business. At Scheller, we are committed to exploring ideas that educate and inform others about the profound impact of business on our lives and the world.

In this episode, Beril Toktay, Regents' Professor and faculty director of the Ray C. Anderson Center for Sustainable Business, defines net zero and discusses some ways to alleviate climate change by reducing carbon emissions to the point of net zero emissions.

Globally, most major polluters, such as China, the U.S., India, and the EU, are among over 140 nations with net-zero goals, which encompasses roughly 88 percent of global emissions. Meeting the Paris Agreement's 1.5°C climate threshold requires 45 percent emissions cut by 2030 and net-zero emissions by 2050 (United Nations Climate Action).

Toktay describes ways this can be accomplished in different business sectors. For example, in the energy sectors, this means moving from fossil fuels to renewable technologies, and in the transportation sector, moving to electrification and innovative battery technologies as well as developing the infrastructure to support these initiatives. These efforts help move businesses towards achieving net zero as well as providing cleaner air and water, and better health outcomes to the global population.

Listen as Toktay discusses what net zero means, the importance of getting to net zero, and how businesses can help reduce carbon emissions.

Lorrie Burroughs

Professor Christopher W. Jones Wins ACS Murphree Award

Sep 13, 2024 —

Chris Jones

Professor Christopher W. Jones, the John F. Brock III School Chair of Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE), is winner of the American Chemical Society’s 2025 E. V. Murphree Award in Industrial and Engineering Chemistry.

Jones will receive the award at the American Chemical Society (ACS) meeting in San Diego, in March 2025. The ACS National Awards encourage the advancement of chemistry in all its branches, support research endeavors, and promote the careers of chemists.

The Murphree Award (including $5,000) won by Jones recognizes fundamental research in industrial and engineering chemistry, the development of chemical engineering principles, and its application to industrial processes.

Associate Professor Matthew McDowell Selected for Emerging Leaders Program

Aug 23, 2024 — Atlanta, GA

Matthew McDowell

Matthew McDowell, Carter N. Paden, Jr. Distinguished Chair and associate professor in the George W. Woodruff School of Mechanical Engineering, has been selected to participate in Georgia Tech’s Emerging Leaders Program. He is among 16 faculty members who will join the program’s ninth cohort.

“On behalf of Institute leadership, we are proud to welcome the next cohort of the Emerging Leaders Program,” said Steven W. McLaughlin, provost and executive vice president for Academic Affairs. “Opening the program to a broader pool of individuals, including our talented research faculty, has been an important programmatic expansion as we seek to foster the leadership aspirations of faculty of all paths. This intensive program is an excellent professional investment, and we applaud the new cohort’s commitment to their careers and to the Institute.”

Starting in Fall 2024 and continuing through Spring 2025, McDowell and other participants will take part in leadership development activities that include a kick-off retreat, regular workshops, small group work, and leadership coaching.

Professor Krista Walton Wins 2024 AIChE Award for Excellence in Industrial Gases Technology

Aug 29, 2024 — Atlanta, GA

Professor Krista Walton was selected as the recipient of the 2024 Institute Award for Excellence in Industrial Gases Technology from the American Institute of Chemical Engineers (AIChE).

Walton, Georgia Tech’s associate vice president for Research Operations and Infrastructure and the Robert "Bud" Moeller Faculty Fellow in Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE), will receive the award at the AIChE meeting in San Diego, California, this October.

Walton focuses her research on the synthesis, characterization, and scale-up of metal-organic frameworks (MOFs) and other porous materials for adsorption-based gas separations.

Starting more than a decade ago, Walton became one of the few researchers in the world to focus on understanding the chemical stability of MOFs and has gained an international reputation for her work by helping shape the landscape of MOF applications in separations. She has published more than 135 peer-reviewed articles, including a seminal review on the water stability of MOFs in 2014.

Meisha Shofner Selected for ELATES National Leadership Program

Aug 28, 2024 — Atlanta, GA

Meisha Shofner ELATES Fellow 2024-2025

Meisha Shofner, professor in the School of Materials Science and Engineering (MSE), has been selected for the 2024-2025 class of Drexel University’s Executive Leadership in Academic Technology, Engineering and Science (ELATES) program.

The ELATES program is a national leadership development program designed to promote women in academic STEM fields and faculty allies of all genders into institutional leadership roles.

“I am excited to be selected as an ELATES Fellow. I am grateful for the support from Georgia Tech’s College of Engineering that made this opportunity possible and especially support from Dean Raheem Beyah, Associate Dean Kim Kurtis, and MSE School Chair Natalie Stingelin. I am looking forward to learning from this amazing community of women leaders in higher education,” Shofner said.

“I was drawn to the ELATES program because of its focus on developing the skills needed to lead university initiatives with an operational focus, and I will be putting that knowledge into practice as I develop an institutional action project as part of the program.”

2023 RBI Spring Workshop Experience From a Student's Perspective - Part 4

Oct 11, 2023 — Atlanta, GA

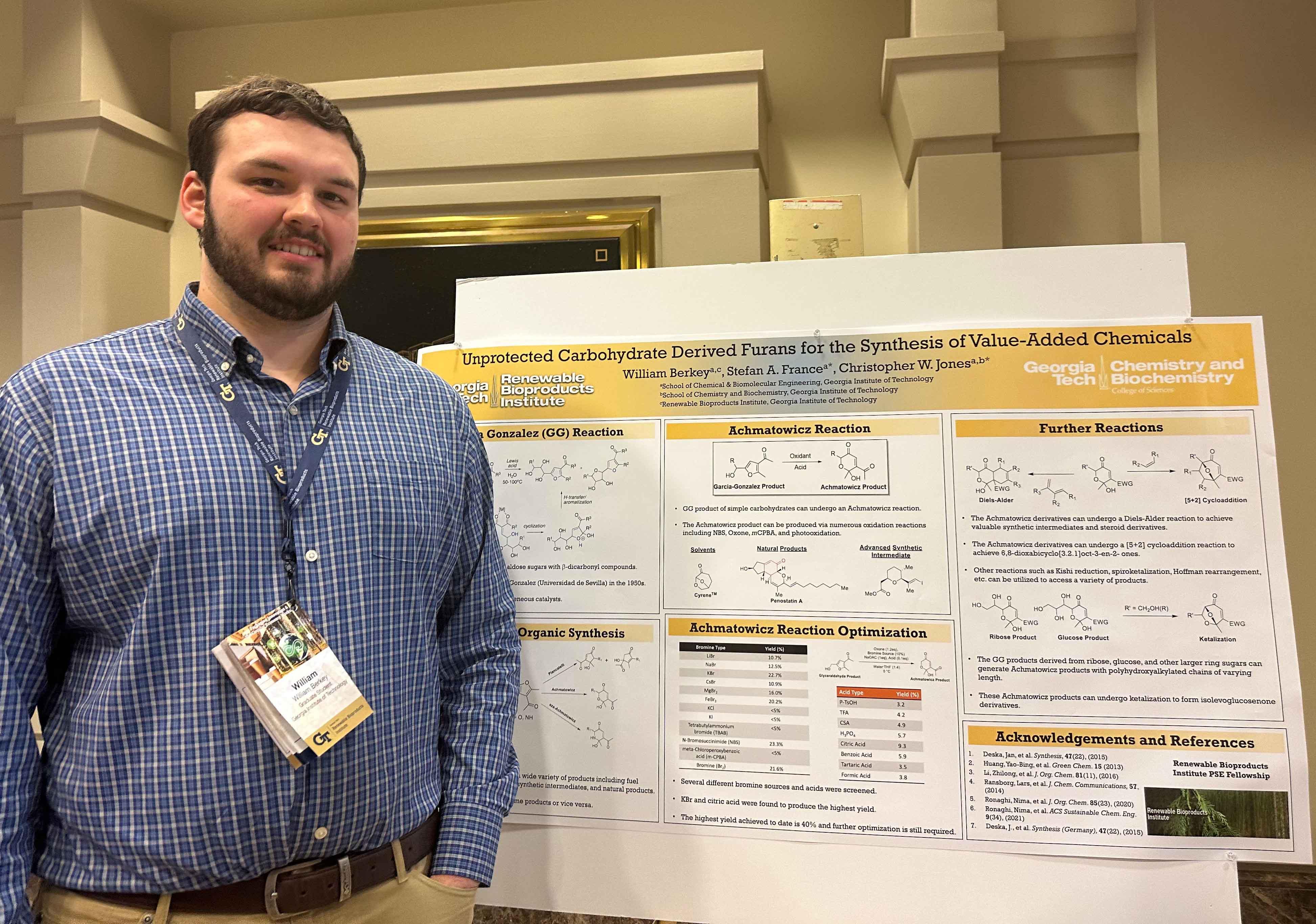

William Berkey at the 2023 RBI Spring Workshop on Innovations in Packaging and the Circular Economy

This is part four of the student experiences series. William Berkey, a Ph.D. candidate in chemistry shares his experience from the 2023 RBI Spring Workshop on "Innovations in Packaging and Circular Economy."

Tell us about yourself.

My name is William Berkey. I got my undergraduate degree in chemistry from Davidson College in North Carolina. I am getting my Ph.D. in chemistry at Georgia Tech. I am co-advised by Stefan France and Christopher Jones. I work on the upcycling of carbohydrates to yield furan-containing building blocks as platforms chemicals and precursors to value-added fuels, materials, and products. Specifically, I work with the Garcia Gonzalez reaction and the Achmatowicz reaction.

The paper I just published as the second author with my mentor Caria Evans (first author) is about converting amino acids — a renewable feedstock — to functionalities pyrroles that can be used for drug molecule development or other bio-active compounds.

How was your experience at the RBI workshop?

I really enjoyed the RBI workshop. It was interesting to see other people’s research and talk with fellow researchers on solving problems and potentially collaborating. The diverse set of talks from industrial, government, and research collaborators shows the wide set of problems still to be solved and different viewpoints on how to solve them. My main takeaway is that through collaboration, solutions to a wide range of problems affecting the industry can be achieved.

What was your main takeaway from the poster session?

What stood out during the poster session was the wide variety of topics that my peers were researching and the interesting findings they discovered. I interacted with several industrial representatives and a fellow Davidson alumnus who works in forest management. I received great advice on how to advance my research as well as how to pursue potential next steps in application.

What more would you like to see in future events at the Renewable Bioproducts Institute?

I would like to see more talks on biorefining. I am interested in interacting with potential collaborators. I would like to see new seminars on research problem-solving or project idea creation.

Priya Devarajan | Research Communications Program Manager, RBI