Navigating the Federal Government Shutdown

Oct 01, 2025 —

As of Oct. 1, the U.S. government has failed to reach a spending agreement in time to avoid a shutdown of the federal government. Due in part to financial planning, the Institute does not expect any significant effect on its operations in the immediate term. As in previous situations, a Georgia Tech working group has been assessing the potential of a shutdown and planning mitigation strategies to help ensure business continuity as lawmakers negotiate to reach an agreement.

“Georgia Tech has successfully navigated these situations in the past, and we are modeling scenarios on how the shutdown may affect cash flow and campus operations over time,” said Kim Toatley, vice president for Finance and Planning and chief financial officer. “While we are hopeful that an agreement will be reached soon, we are working to adapt our financial planning and activities to this fluid situation.”

U.S. government programs represent more than $100 million per month in federal funding for research activities at Georgia Tech. If the shutdown continues beyond a few weeks, mitigation strategies will need to be implemented to preserve cash and maintain campus operations. Some strategies include conserving available reserves; requiring Cabinet-level approval for certain purchases, hiring, and non-essential travel; and slowing down select research.

Activities related to ongoing grants and contracts will continue, but additional support and administrative assistance from sponsors may be limited. New grant applications will be on hold, and no new awards will likely be issued. Georgia Tech will continue to submit invoices and make cash requests as systems allow, but payment from sponsors will be delayed. Additional actions will be considered as circumstances warrant, and the Institute will remain committed to limiting the effect on students, faculty, and staff. Researchers can consult Georgia Tech guidance here: osp.gatech.edu/federal-government-shutdown-guidance.

The working group is closely monitoring this situation and will continue to provide information in the coming days.

Rachael Pocklington

Institute Communications

Georgia Tech Startup Sets Sights on Transforming Heart Failure Care

Sep 23, 2025 —

Heart failure remains one of the most challenging conditions to monitor outside the clinic. Patients may experience changes in symptoms, such as fatigue or shortness of breath, between visits, yet many current devices provide limited data, leaving physicians without continuous insight into heart function.

“Despite advances in digital health, continuous monitoring of the heart’s mechanical function has remained difficult outside clinical settings,” said Omer Inan, researcher and entrepreneur at Georgia Tech. “Patients and physicians have long needed a tool that provides deeper, real-time insights into heart performance without invasive procedures. We decided to tackle that problem head-on with a wearable device.”

Xiao Liu Leads $1.5M NSF Project to Address Urban Resilience Challenges

Sep 26, 2025 —

Xiao Liu

A multi-university research team led by Xiao Liu, the David M. McKenney Family Associate Professor in the H. Milton Stewart School of Industrial and Systems Engineering (ISyE), has been awarded a $1.5 million grant from the National Science Foundation (NSF). The project, “AccelNet Implementation Phase 1: International Networks Towards Future Resilience of U.S. Urban Socio-Technical Systems,” brings together experts across the country and around the world to tackle one of society’s most pressing challenges: building resilient cities for the future.

Liu serves as the principal investigator (PI), joined by co-PIs from five universities: Hiba Baroud (Vanderbilt University), Linyin Cheng and Song Yang (University of Arkansas), Jennifer Pazour (Rensselaer Polytechnic Institute), Yisha Xiang (University of Houston), and Xiang Zhou (Harvard University). Together, they are launching Resilient-NET, a collaborative research team and network designed to connect U.S. and international research communities focused on the resilience of urban socio-technical systems.

The project takes a holistic approach to urban resilience, focusing on three interwoven dimensions:

- Technology (the “New Dimension”) – examining the integration of AI-enabled systems into infrastructure and mobility networks.

- People (the “Missing Puzzle”) – exploring the complex and evolving interactions between humans and technology.

- Environment (the “Uncertainty Accelerator”) – addressing the rising frequency of extreme natural events that disrupt urban systems, with the goal of improving predictive modeling, disaster preparedness, and the development of urban digital twins.

By combining these perspectives, the team aims to generate new insights into how technology, society, and climate intersect, and to chart pathways toward resilient, sustainable, and livable cities.

“Urban resilience is an interdisciplinary grand challenge,” Liu said. “It requires coordination of talents and resources to create transdisciplinary solutions. Through Resilient-NET, we hope to consolidate a roadmap for resilient urban ecosystems and nurture the next generation of leaders who will tackle these problems on a global scale.”

The project benefits from the support and collaboration from multiple research fields within ISyE such as System Informatics and Control, Energy and Sustainable Systems, Data Science and Statistics, and Supply Chain and Logistics Institute (SCL) and AI4OPT of Georgia Tech, domestic partners including the Weatherhead Center for International Affairs at Harvard, the Natural Hazards Center at the University of Colorado, IBM Research, the Taylor Geospatial Institute, and Argonne National Laboratory, as well as international partners, including the Singapore-ETH Center on Future Resilient Systems, Karlsruhe Institute of Technology in Germany, Global South partners such as Tecnológico de Monterrey and Universidad Panamericana Guadalajara, and the 4TU Centre for Resilience Engineering in the Netherlands.

Looking ahead, the researchers envision Resilient-NET as a long-term hub that not only advances scientific understanding but also equips students and early-career researchers with global leadership skills. At a time when artificial intelligence is rapidly reshaping infrastructure and mobility, Liu and his collaborators see this work as critical to ensuring that urban systems continue to function in the face of uncertainty.

Liu shares, “Our vision is that Resilient-NET will serve as a bridge, linking disciplines, institutions, and countries, to build cities that are not only technologically advanced, but also safe, welcoming, and adaptable for generations to come.”

Erin Whitlock Brown, Communications Manager II

Georgia Tech Students Take Charge with New AI and Engineering Course

Sep 26, 2025 —

Two Georgia Tech Ph.D. students created a student-run, faculty-graded, fully-accredited course that links math, engineering and machine learning.

Andrew Rosemberg, with assistance from Michael Klamkin, both student researchers with the U.S. National Science Foundation AI Research Institute for Advances in Optimization (AI4OPT), designed the course to bridge gaps they saw in existing classrooms.

“While Georgia Tech offers excellent courses on optimization, control, and learning, we found no single class that connected all these fields in a cohesive way,” Rosemberg said. “In our research, it was clear these topics are deeply interconnected.”

Problem-driven learning

The course starts with fundamental problems and works backward to the methods required to solve them. Rosemberg said this approach was intentional. He said that courses often center around methods in isolation rather than showing how the methods contribute to the larger context. This keeps the course focused on problem-driven discovery.

The class also serves as a way for Rosemberg and Klamkin to strengthen their own teaching and mentoring skills.

Goals and structure

The primary goal of the course is to help students build a clear understanding of how mathematical programming, classical optimal control, and machine learning techniques such as reinforcement learning connect to one another. Students are also working to produce a structured book by the end of the semester.

“The hope is that this resource will not only solidify our own learning but also serve as a guide for other students who want to approach these problems in the future,” Rosemberg said.

Responsibilities are distributed across participants, with each student delivering lectures, reviewing peers’ work, and contributing to collective discussions. Rosemberg and Klamkin provide additional support where needed, while faculty mentor and director of AI4OPT, Pascal Van Hentenryck, ensures the class stays aligned with broader academic objectives.

Student ownership and collaboration

Rosemberg noted that the student-led model gives students a deeper sense of ownership, making them responsible for their own learning, and having a stronger impact. This model allows students to determine what to learn and why, which promotes critical thinking.

The course uses GitHub as its primary workflow platform. Rosemberg said adds transparency and prepares students for real-world research practices.

“GitHub functions much like university systems such as Canvas or Piazza. It also has the added benefit of making all contributions visible to the world,” Rosemberg explained. “This helps students take pride and ownership of their work, while also introducing them to Git, an essential tool for software development and modern STEM research.”

Emerging insights and challenges

Students have begun aligning their research with course themes, including shaping qualifying exam topics around the intersections of operations research, optimal control and reinforcement learning. Rosemberg said exploring the comparative strengths of these fields side by side has been one of the most rewarding outcomes.

Balancing independence with guidance has proven to be the greatest challenge. He said they have been evolving alongside the students in real time and have learned to emphasize mutual responsibility to promote the collective progress of the class.

Looking ahead

Rosemberg said future iterations of the course may place more emphasis on setting expectations early, given the effort required to deliver a lecture in this format.

His advice for others who may want to replicate the model is to focus on building a committed core team.

“Start with a small, motivated group,” Rosemberg said. “Like a startup, success depends less on the structure and more on the dedication of the people involved.”

Jaci Bjorne

Decades in the Making: Seeing the Full Impact From Air Pollution Reductions

Sep 26, 2025 — Atlanta, GA

Iridescent clouds before sunset / Source: NOAA

Researchers at Georgia Tech have analyzed the seasonal differences of sulfate aerosols — a major pollutant in the United States — to examine the long-term impact from sulfur dioxide (SO₂) emission reductions since the enactment of the Clean Air Act amendments in 1990.

School of Earth and Atmospheric Sciences Professor Yuhang Wang and his team studied the factors affecting SO₂ and sulfate concentrations during winter and summer in the “Rust Belt” — from New York through the Midwest — and the Southeast regions of the U.S. over two decades (2004 to 2023). Supported by the National Science Foundation and Georgia Tech’s Brook Byers Institute for Sustainable Systems, the team also developed an ensemble machine learning approach to project seasonal patterns until 2050.

“Power plants, particularly those burning coal and oil, are a major source of SO₂ emissions in these regions,” says Wang, who co-authored, with Ph.D. students Fanghe Zhao and Shengjun Xi, the study recently published in Environmental Science & Technology Letters.

Seasonal differences in atmospheric chemistry

In the U.S., the chemistry in the atmosphere varies among the seasons. During summer, solar radiation from ample sunlight activates oxidant reactions that produce hydrogen peroxide (H₂O₂) in the atmosphere. The supply of H₂O₂ is determined by the amount of emitted air pollution, and once in the atmosphere, H₂O₂ can oxidize SO₂ quickly into sulfate aerosols in the aqueous phase.

Sulfate aerosols from the oxidation of SO₂ contribute to the formation of particulate matter less than 2.5 micrometers in diameter (PM2.5). Particulate sulfate poses significant environmental and public health risks, including air pollution, acid rain, and circulatory and respiratory issues.

“The supply of H₂O₂ in summer is eight times greater than in winter — a huge difference — which means sulfate concentrations are generally higher in summer and a reduction in SO₂ emissions leads to a proportional decrease in sulfate concentrations,” explains Wang. “When SO₂ emissions exceed the available supply of H₂O₂ in winter, the reduction in sulfate concentrations can be much smaller because of a ‘chemical damping’ effect that causes sulfate levels to decline more slowly than SO₂ emissions.”

Narrowing the disparities between seasonal sulfate levels

The study’s two-decade observations revealed distinct patterns in the reduction of SO₂ emissions and sulfate concentrations during winter and summer.

While SO₂ emissions significantly decreased in both seasons over time — primarily from the Clean Air Act and more power plants transitioning from coal to natural gas — the reduction of sulfate concentrations initially showed large seasonal differences. However, over the past decade, the disparity between winter and summer sulfate levels narrowed as SO₂ emissions decreased.

According to Wang, the seasonal disparity of sulfate was caused by changing chemical regimes in winter over time. Although the lower supply of H₂O₂ remained stable in winter, SO₂ wintertime emissions were higher from 2004 to 2013, then dropped below the level of H₂O₂ after 2013 — reaching parity with the levels of reduced SO₂ emissions in the summer.

“When you have this complexity of atmospheric chemistry, there is a non-linear effect in winter — as SO₂ emissions decreased, sulfate aerosol production efficiency increased until 2013, then flattened as of today. The reduction in sulfate aerosols initially lagged behind the decrease in SO₂ emissions but eventually caught up as a result of sustained air quality control efforts,” says Wang. “Conversely, there is a simple, linear effect in summer — the more SO₂ emissions, the more sulfate aerosols in the atmosphere — and if you reduce one, the other is reduced by the same proportion.”

Decades-long full impact

From now until 2050, the researchers’ machine learning projections indicate a continuing decrease of winter and summer sulfate levels, which are currently around 20 percent, as SO₂ emission controls achieve comparable efficacy across the seasons.

“We’re now seeing the full impact from the Clean Air Act,” concludes Wang, “and the nation’s sustained effort in pollution reduction is key to improving air quality and health outcomes.”

School of Earth and Atmospheric Sciences Professor Yuhang Wang and his team co-authored the study, “Chemically Induced Decline in Wintertime SO₂ Emission Control Efficacy,” which was published in Environmental Science & Technology Letters.

Ph.D. student Fanghe Zhao

Jess Hunt-Ralston

Director of Communications

College of Sciences at Georgia Tech

Writer: Annette Filliat

Editor: Lindsay Vidal

From Lab to Life: Inside the Institute for Neuroscience, Neurotechnology, and Society

Sep 25, 2025 —

Researchers across Georgia Tech are joining forces to explore the brain — advancing science, technology, and society through interdisciplinary collaboration.

The brain is the most intricate system known to science — billions of cells forming dynamic networks that allow us to think, feel, move, and adapt. Yet despite decades of research, much about how the brain works remains a mystery. At the same time, neurological and neuropsychiatric conditions are on the rise, affecting more than one-third of the global population and costing trillions in healthcare and lost productivity.

Understanding the brain is key to unlocking human health and flourishing. The need has never been more urgent, but this challenge is too vast for any single discipline to solve alone.

That’s why Georgia Tech recently launched the Institute for Neuroscience, Neurotechnology, and Society (INNS). A step toward a more connected, collaborative future, INNS brings together experts from across Georgia Tech’s seven colleges and the Georgia Tech Research Institute (GTRI) to study the brain in ways that connect scientific discovery with technological innovation and real-world societal needs.

INNS supports research that crosses traditional academic boundaries. As an Interdisciplinary Research Institute (IRI), it builds community, fosters collaboration, and fills critical gaps in education, professional development, and research infrastructure.

“Georgia Tech has a long-standing culture of interdisciplinary collaboration — it’s in our DNA,” says INNS Executive Director Chris Rozell. Rozell also serves as Julian T. Hightower Chaired Professor in the School of Electrical and Computer Engineering. “INNS builds on that strength to create a space where breakthroughs in neuroscience and neurotechnology can move from lab to life, impacting real people in real ways.”

A Community Built to Collaborate

INNS is home to a growing network of faculty, students, and research centers spanning the full spectrum of Georgia Tech’s research expertise. This diversity is not just a feature, it’s the foundation.

That foundation was laid over decades of growth, vision, and grassroots momentum. Georgia Tech welcomed its first neuroscience-focused faculty member in 1990, sparking a steady expansion of brain-related research across campus. As more faculty joined and new focus areas emerged, a vibrant, cross-disciplinary community began to take shape.

In 2014, that community organized under the name GT Neuro, a grassroots initiative that united researchers who shared a passion for understanding the brain. This collective energy led to new educational programs, including the launch of Georgia Tech’s undergraduate neuroscience major in the College of Sciences.

“Our undergraduate students absolutely love teaching others about Neuroscience,” said Christina Ragan, director of Outreach for the Undergraduate Neuroscience Program and senior academic professional in the School of Biological Sciences. “I'm really excited to explore ways for INNS to connect our neuroscience community at Tech with the public.”

By 2023, the Neuro Next Initiative launched to bring together leaders from across campus and chart a strategic path forward — the result of nearly two years of community-driven planning to formalize and expand Georgia Tech’s neuroscience ecosystem.

“The launch of INNS has built on the momentum of the Neuro Next Initiative, which ignited crucial conversations and fostered new collaborations between researchers at GTRI and Georgia Tech faculty,” says Tabbitha Rosenbalm, GTRI senior research engineer. “The remarkable demonstration at Interface Neuro — witnessing a quadriplegic man walk and communicate thanks to innovative research — underscores the transformative breakthroughs possible when academic and applied researchers unite. INNS is uniquely positioned to serve as a catalyst, propelling Atlanta, Georgia Tech, and GTRI as national leaders in neurotechnology, driving advancements in both human health and engineering innovation.”

INNS is also helping shape the future of education. A new interdisciplinary Ph.D. program in neuroscience and neurotechnology welcomed its first cohort this fall, and INNS is poised to support it with professional development, research opportunities, and community engagement.

Breaking Boundaries to Advance Brain Science

Whether it’s developing neurotechnologies, designing therapeutic environments, or exploring the ethical implications of brain research, INNS is here to support work that spans fields and impacts lives.

“To responsibly address the societal and human impacts of advances in neuroscience and neurotechnology, we first need to understand them,” said Margaret Kosal, professor and director of Graduate Students in the Ivan Allen College of Liberal Arts. “That requires real and substantive collaboration beyond traditional engineering or biology labs.”

One example of INNS in action is the Smart Transitional Home Lab, a project funded by the inaugural INNS/Shepherd Center Seed Grant. This initiative brings together experts in architecture, inclusive design, neuroengineering, and rehabilitation to prototype environments that actively support stroke recovery, blending rigorous research with human-centered design.

“The establishment of INNS creates a powerful platform where diverse minds, from neuroscience to architecture to rehabilitation, can converge around a shared mission to advance human health,” says Hui Cai, professor in the School of Architecture, executive director of the SimTigrate Design Center, and co-leader of the project. “It enables interdisciplinary work with the potential to transform lives and redefine how we design for healing and recovery.”

“From whole brain recordings, to mapping the connectome, to the incredible advances in artificial intelligence, it's never been a more exciting time to study the mind and brain,” says Bob Wilson, director of the Center of Excellence for Computation and Cognition and associate professor in the School of Psychology. “I'm extremely excited for INNS to act as a central hub, building the neuroscience community at Georgia Tech and beyond.”

Join Us

INNS is more than an institute, it’s a growing, vibrant community of researchers, educators, students, and partners. Together, we’re working to understand the brain, develop technologies that improve lives, and ensure those innovations serve society responsibly.

Whether you're a student, researcher, policymaker, or simply curious about the brain, INNS is your gateway to interdisciplinary neuroscience at Georgia Tech. Get involved at neuro.gatech.edu.

Audra Davidson

Research Communications Program Manager

Institute for Neuroscience, Neurotechnology, and Society

Institute Communications

Inaugural Cohort of Graduate Apprentices Announced

Sep 24, 2025 —

The inaugural cohort of the IMS graduate student apprenticeship program and their mentors.

The Institute for Matter and Systems (IMS) at Georgia Tech has selected nine graduate students for the inaugural cohort of its Graduate Apprenticeship Program, officially launching the initiative. The program offers graduate students a unique opportunity to gain hands-on experience in advanced materials research and systems-level problem-solving.

Following a competitive application process, IMS selected students whose research interests align with the institute’s core capabilities in fabrication and characterization. Apprenticeships begin October 1, 2025, with students working closely with IMS staff and faculty mentors to support facility operations and contribute to cutting-edge research.

“The Graduate Student Apprenticeship program opens the door for students to gain hands-on experience in our cleanroom and characterization facilities,” said Eric Vogel, executive director of IMS. “By working directly with advanced tools and processes, they not only strengthen their research skills but also build the practical expertise that will set them apart in industry.”

The IMS Graduate Apprenticeship Program is a structured, paid alternative to traditional teaching assistantships. Apprentices commit 10 hours per week to facility operations and receive support for 50% of their graduate stipend and tuition.

"This program is an exciting opportunity for us to advance and support graduate training and education,” said Anna Osterholm, principal research scientist and IMS Graduate Apprenticeship Program coordinator. “It provides financial support to both students and faculty, and we expect to enhance the capacity of IMS core facilities, which continue to see a steady growth from both internal and external users each year.”

The selected apprentices represent a diverse range of disciplines and will receive training on micro/nanofabrication or materials characterization tools. In addition, they will assist with instrumentation calibration, process development, sample testing, and data analysis for internal and external research projects.

The 2025 Cohort

- Kayla Chuong, Ph.D. student in the School of Materials Science and Engineering

- Grace Crim, Ph.D. student in the School of Electrical and Computer Engineering

- Parker Dulin, Ph.D. student in the School of Chemical and Biomolecular Engineering

- Isaiah Ertel, Ph.D. student in the School of Physics

- Matthew Kim, M.Sc. student in the School of Electrical and Computer Engineering

- Calib Lanier, Ph.D. student in the School of Chemical and Biomolecular Engineering

- Justin Nakamura, Ph.D. student in the School of Materials Science and Engineering

- Chinaza Ogbonna, Ph.D. student in the George W. Woodruff School of Mechanical Engineering

- Eric Zhang, Ph.D. student in the School of Physics

Mentors

- Stephan Turano

- Todd Walters

- Josh Davies-Jones and team

- David Tavakoli

- Durga Gajula and team

- Hang Chen

Amelia Neumeister | Research Communications Program Manager

The Institute for Matter and Systems

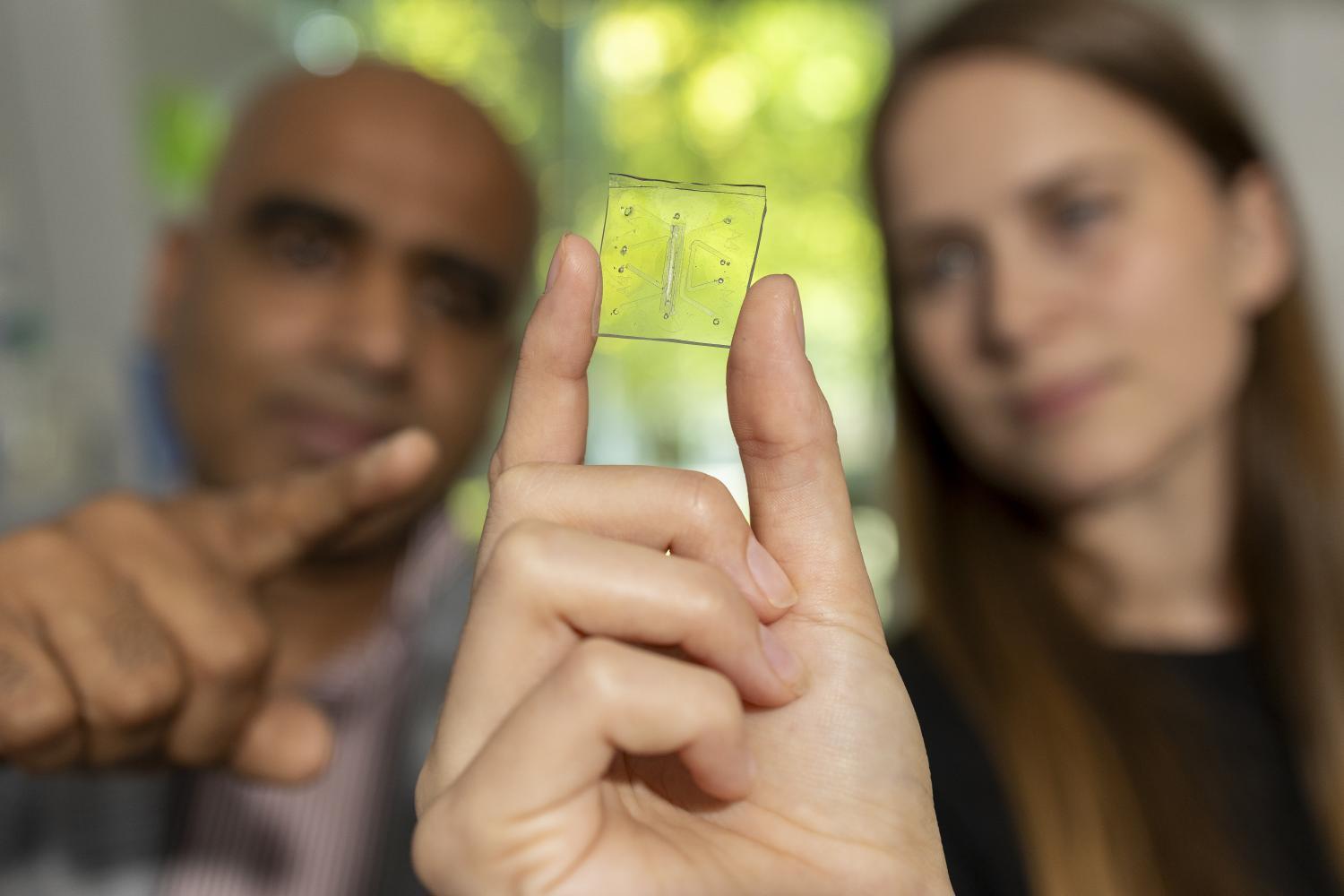

Breathtaking Breakthrough: Lung-on-a-Chip Defends Itself

Sep 24, 2025 —

Ankur Singh and Rachel Ringquist point to the microscopic lung-on-a-chip that has a built-in immune system.

On a clear polymer chip, soft and pliable like a gummy bear, a microscopic lung comes alive — expanding, circulating, and, for the first time, protecting itself like a living organ.

For Ankur Singh, director of Georgia Tech’s Center for Immunoengineering, watching immune cells rush through the chip took his breath away. Singh co-directed the study with longtime collaborator Krishnendu “Krish” Roy, former Regents Professor and director of the NSF Center for Cell Manufacturing Technologies at Tech and now the Bruce and Bridgitt Evans dean of engineering and University Distinguished Professor at Vanderbilt University. Rachel Ringquist, Roy’s graduate student, and now a postdoctoral fellow with Singh, led the work as part of her doctoral dissertation.

“That was the ‘wow’ moment,” Singh said. “It was the first time we felt we had something close to a real human lung.”

Lung-on-a-chip platforms provide researchers a window into organ behavior. They are about the size of a postage stamp, etched with tiny channels and lined with living human cells. Roy and Singh’s innovation was adding a working immune system — the missing piece that turns a chip into a true model of how the lung fights disease.

Now, researchers can watch how lungs respond to threats, how inflammation spreads, and how healing begins.

The Human Stakes

For millions of people struggling with lung disease, everyday life can feel nearly impossible, whether it’s climbing stairs, carrying groceries, or even laughing too hard. Doctors and scientists have attempted for decades to unlock what really happens inside fragile lungs.

"This unique lung-on-a-chip model opens new, preclinical pathways of discovery that will allow researchers to better understand the interplay of immune responses to severe viral infections and evaluate critical antiviral treatments,” said Roy.

For Singh, the Carl Ring Family Professor in the George W. Woodruff School of Mechanical Engineering with a joint appointment in the Wallace H. Coulter Department of Biomedical Engineering, this research is deeply personal. He lost an uncle when an infection overwhelmed his cancer-weakened immune system.

“That experience stays with you,” Singh reflected. “It made me want to build systems that could predict and prevent outcomes like that, so fewer families go through what mine did. I think about my uncle all the time. If work like this means fewer families lose someone they love, then it’s worth everything.”

That motivation pushed his team to reimagine what a lung-on-a-chip could do, setting the stage for the breakthroughs that followed.

When the Lung Fought Back

The turning point came when Roy’s and Singh’s team peered through a microscope and saw something no one had ever witnessed on a chip: blood and immune cells coursing through tiny vessel-like structures, behaving just as they do in a living lung.

For years, researchers had struggled to add immunity to organ-on-a-chip systems. Immune cells often died quickly or failed to circulate and interact with tissue the way they do in people. the team solved that problem, creating a chip where immune cells could survive and coordinate a defense.

“It was an amazing breakthrough moment,” Singh said.

The true test came when the team introduced a severe influenza virus infection. The lung mounted an immune response that closely mirrored what doctors see in patients. Immune cells rushed to the site of infection, inflammation spread through tissue, and defenses activated in response.

“That was when we realized this wasn’t just a model,” Singh said. “It was capturing the real biology of disease.”

Singh and Roy’s research is published in the journal Nature Biomedical Engineering.

A More Human Approach

For decades, lung research has relied on animal models. But mice don’t get asthma like children. Their bodies don’t mount the same defenses.

“Five mice in a cage may respond the same way, but five humans won’t,” Singh explained. “Our chip can reflect that difference. That’s what makes it more accurate, and why it could dramatically reduce the need for animal models.”

Krish Roy emphasized its potential.

“The Food and Drug Administration’s strategic vision on reducing animal testing and developing predictive non-animal models aligns perfectly with our work. This device goes further than ever before in modeling human severe influenza and providing unprecedented insights into the complex lung immune response,” he said.

Fighting More Than the Flu

What began with influenza now expands to a wider range of diseases. Roy and Singh believes the platform can be used to study asthma, cystic fibrosis, lung cancer, and tuberculosis. The researchers are also working to integrate immune organs, showing how the lung coordinates with the body’s defenses.

The long-term vision is personalized medicine: chips built from a patient’s own cells to predict which therapy will work best. Scaling, clinical validation, and regulatory approval will take years, but Singh is undeterred.

“Imagine knowing which treatment will help you before you ever take it,” Singh said. “That’s where we’re headed.”

Where we’re headed, the future doesn’t wait for illness. Instead, it anticipates it, intercepts it, and rewrites the outcome.

Georgia Tech postdoctoral researcher Rachel Ringquist was the first author leading the study.

This research was supported by Wellcome Leap, with additional funding from the National Institutes of Health, Carl Ring Family Endowment, and the Marcus Foundation.

Ringquist, R., Bhatia, E., Chatterjee, P. et al. An immune-competent lung-on-a-chip for modelling the human severe influenza infection response. Nature Biomedical Engineering, September 2025 Vol.9 No.9

DOI: https://doi.org/10.1038/s41551-025-01491-9

Michelle Azriel Sr. Writer-Editor

Advanced Manufacturing Takes Off in Georgia Classrooms

Sep 23, 2025 —

Students across Georgia are designing and 3D printing pinewood derby cars as part of a new hands-on advanced manufacturing initiative.

Smart manufacturing, data-driven design, and artificial intelligence aren’t just buzzwords — they are fields that are creating high-paying, high-tech careers across the country. In rural communities across Georgia, these advanced manufacturing roles are growing, but the talent pipeline isn’t keeping pace.

“It’s not just about creating jobs, it’s about filling them,” says Tom Kurfess, Regents’ Professor and executive director of the Georgia Tech Manufacturing Institute (GTMI). “To do that, we need to show students how exciting and innovative manufacturing can be. Manufacturing has really changed over the past few years. Today, going from an idea to a physical part is much easier to do. It is fun and exciting to bring ideas to life and to actually hold the results in your hands.”

GTMI is working to reignite student interest in the art and science of making through its new K–12 initiative: the Advanced Manufacturing Pathways (AMP) Program. Modeled after Georgia Tech’s Rural CS Initiative, AMP empowers schools with faculty expertise, cutting-edge equipment, and a hands-on curriculum to give students early exposure to the tools, technologies, and creativity behind modern manufacturing while building a pipeline of future talent ready to thrive in high-tech careers.

Funded by the Southwest Georgia Regional Commission (SWGRC), AMP is kicking off in three school districts this fall — Decatur County, Thomas County, and the city of Thomasville — with plans to expand to additional schools in the spring of 2026. The program will start by engaging more than 200 students through hands-on learning, virtual instruction, and in-person lab experiences led by Georgia Tech researchers and faculty.

“Here in Southwest Georgia, we believe that opportunities like this are vital for integrated learning in schools and for growing our future workforce,” says Beka Shiver, economic development and transportation planner for SWGRC. “Workforce development and K-12 integration are at the heart of our Southwest Georgia Ecosystem Building Project, and we are so pleased to be able to provide funding for this program.”

The launch of the AMP Program is centered around Design, Build, Race, a course putting a modern spin on the classic pinewood derby. Students will use digital design, 3D printing, and machining to build and race custom cars, while also learning how to collect and analyze performance data to improve their designs and predict outcomes. The course blends engineering with data science, sparking curiosity and showing students how modern manufacturing is powered by both technical skills and smart data.

“This program delivers real-world industry experience to students while strengthening the talent pipeline that drives innovation, competitiveness, and resilience in advanced manufacturing”, says Steven Ferguson, interim director of operations at GTMI and one of the project’s leaders. “After more than 20 years of driving education and workforce development innovation, I’m more energized than ever to help launch the AMP program to open doors for students and advance U.S. manufacturing leadership.”

Building the Blueprint

Before it evolved into the AMP Program, Design, Build, Race was a course developed by GTMI research engineer Kyle Saleeby in 2023. Originating in GTMI’s Advanced Manufacturing Pilot Facility (AMPF), the course was designed to introduce Morehouse and Georgia Tech students to the possibilities of modern manufacturing through digital design, 3D printing, machining, and competitive creativity.

“Even after the first week, it was powerful to watch students discover how exciting it is to design and manufacture a competition-ready car in a matter of hours,” said Saleeby. “That’s when I knew we were onto something special.”

Saleeby teamed up with Ferguson to transform the course into a broader initiative. The duo engaged colleagues from STEM@GTRI and secured funding from SWGRC to modify the curriculum and scale the course for a high school audience.

“We are thrilled that we have been able to take the lessons learned during the development of the Rural Computer Science Initiative and expand opportunities for students in Southwest Georgia,” says Sean Mulvanity, a senior research associate in the Georgia Tech Research Institute. Mulvanity is one of the founders of the initiative and has been a key contributor to the AMP Program. “We hope this program can grow and expose students across the state to the field of advanced manufacturing.”

Though granted by the SWGRC, funds for the program were provided by Georgia Artificial Intelligence in Manufacturing, a statewide initiative founded by GTMI and Georgia Tech’s Enterprise Innovation Institute to advance AI-driven manufacturing.

To bring AMP into classrooms, Southern Regional Technical College helped set up labs and provide technical support, ensuring schools were ready to launch.

“At all levels, the community has rallied around this program,” says Saleeby. “Providing students with a unique experience learning advanced manufacturing technologies will open countless career opportunities. I cannot wait to see where they go.”

Kyle Saleeby (left) works side-by-side with a teacher to set up precision milling equipment, a key part of the AMP Program’s hands-on curriculum.

With more than two decades of workforce development experience, Steven Ferguson is helping launch a new era of hands-on learning through the AMP Program.

Audra Davidson

Research Communications Program Manager

Georgia Tech Manufacturing Institute

Bakir Named Inaugural GlobalFoundries Termed Chair

Aug 27, 2025 —

Georgia Tech School of Electrical and Computer Engineering (ECE) Professor Muhannad Bakir has been named the inaugural GlobalFoundries Termed Chair in Packaging and 3D Heterogeneous Integration.

The position was established in the spring of 2025 to be awarded to a distinguished ECE faculty member who has demonstrated excellence in research and teaching in the areas of chiplet-based integrated circuit (IC) systems, 2.5D, and 3D IC technologies.

“I am grateful to GlobalFoundries for establishing this chair position in ECE, and honored to be the inaugural recipient,” Bakir said. “Advanced packaging and heterogeneous integration are a key differentiator and driver of innovation in virtually all leading-edge electronic systems from handheld devices to data centers powering AI. ECE’s partnership with GlobalFoundries will position the School for many unique research and educational programs development to support 2.5D and 3D technologies.”

3D heterogeneous integration (3DHI) is a cutting-edge technology that merges various ICs and components, including processors, memory, sensors, and RF modules, into one 3D package.

Bakir is currently the Dan Fielder Professor in ECE and the director of the 3D Systems Packaging Research Center supported by the Institute for Matter and Systems, where he oversees an interdisciplinary approach to electronic packaging research.