Georgia Tech Authors Celebration 2024

Georgia Tech faculty and staff are invited to join the Office of the Executive Vice President for Research and the Library for the annual Georgia Tech Authors Celebration.

This event celebrates Georgia Tech book publications, showcasing the range and depth of scholarship on our campus. The 2024 event honors authors and editors who have published books between January 2022 and December 2023.

A Day’s Work at the RBI Chemical Analysis Lab

Nov 09, 2023 — Atlanta, GA

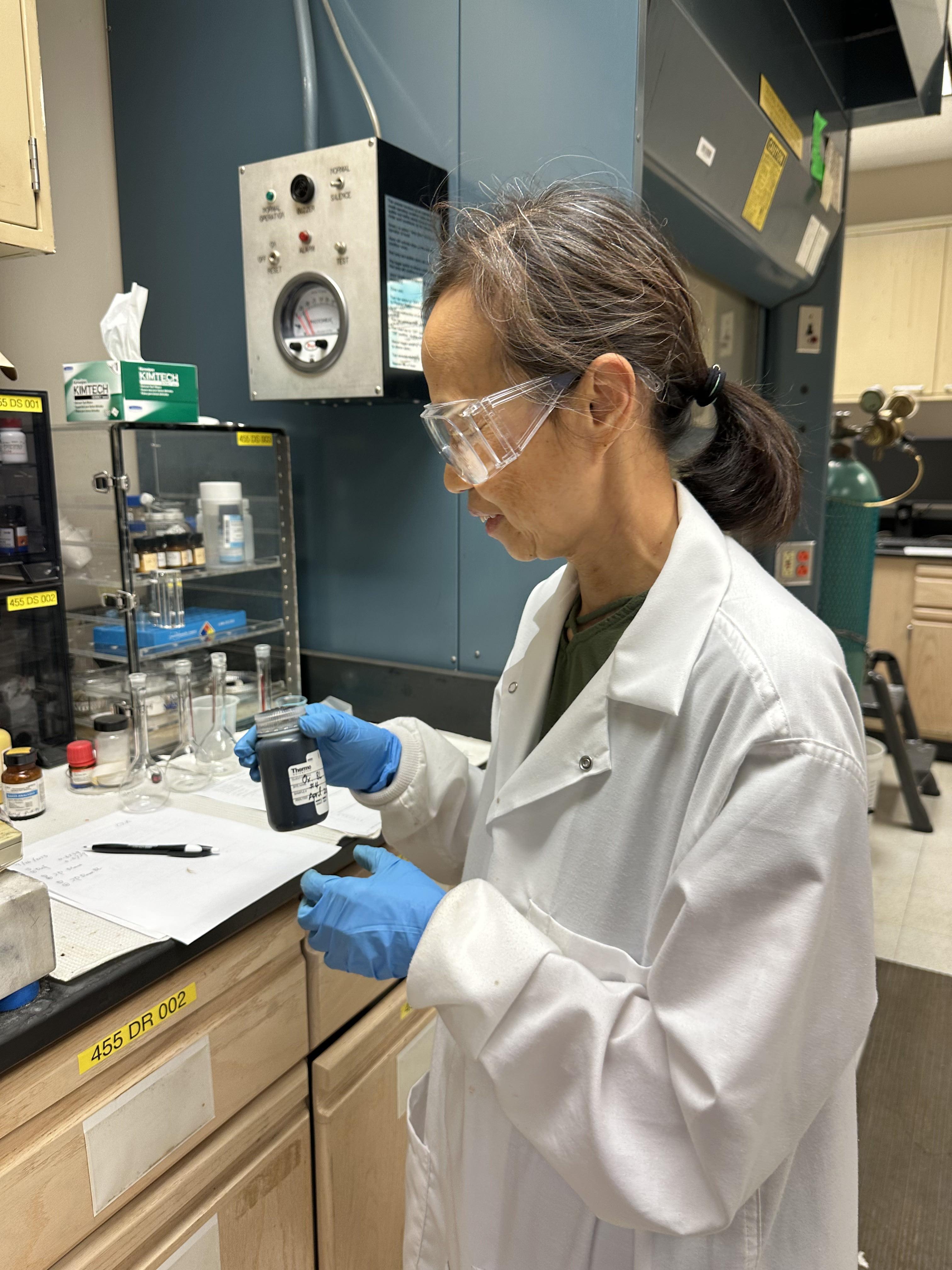

Rallming Yang, Senior Research Scientist and head of the Chemical Analysis Lab explains how FTIR Spectrometer works, at the RBI Chemical Analysis Lab

Providing research testing services to both internal and external stakeholders is an integral function of the Renewable Bioproducts Institute (RBI). These services include chemical analysis; corrosion; paper, board and box testing; pulp analysis; and pulp recovery analysis. Established over 25 years ago, RBI’s testing services are well-known in the industry for their quality and customer service. RBI is one of the ten interdisciplinary research institutes at Georgia Tech that champions innovation in converting biomass into value-added products, developing advanced chemical and bio-based refining technologies, and advancing excellence in manufacturing processes.

The RBI research testing services is a team of professional scientists and engineers who work together to provide information and offer solutions required by a manufacturers and users of biomass products, as well as Georgia Tech faculty and students engaged in research on campus. The multidisciplinary capabilities of the team make them uniquely qualified to address customers' technical needs in the areas of process and product development, and quality control. Where appropriate, the team involves RBI faculty and other staff experts to arrive at the best possible solution for their customers and users.

In this article, we will focus on a day’s work with the chemical analysis team. Headed by Rallming Yang, senior research scientist at RBI, the team is equipped to follow the Technical Association of the Paper and Pulp industry (TAPPI) standard of testing, which only a small number of labs in the country can do, and has also developed some of its own internal protocols. Yang leads two specific characterization programs within RBI: (1) the pulping and bleaching analysis, paper recycling, and recovery lab, and (2) the chemical analysis lab.

The chemical analysis team is busy year-round with research projects and testing services. In addition, during the Spring semester, the team also provides support to a paper science laboratory course for undergraduate and graduate students. In the recent times, chemical analysis of black liquor from pulp mills has kept the team busy with more than 30 projects completed by the team over three months for various industry customers. Currently, black liquor analysis continues to account for over 50% of the workload of the lab.

Black Liquor (BL) is a byproduct of a wood pulping and is released when cellulose fibers are separated from wood chips. BL contains lignin, which is used as a biofuel within the mill, and several other chemicals that are recovered and reused. In most pulp mills, nearly 50-70% of BL is converted into a convenient source of fuel or energy. Due to the important role played by black liquor in a paper mill, it needs to be tested regularly to ensure consistency in composition. The RBI chemical analysis lab gets BL samples from a pulp mill, who contact the lab by email to get their testing request into the queue. The process involved in the testing is very intense and has multiple steps that need to be carefully administered.

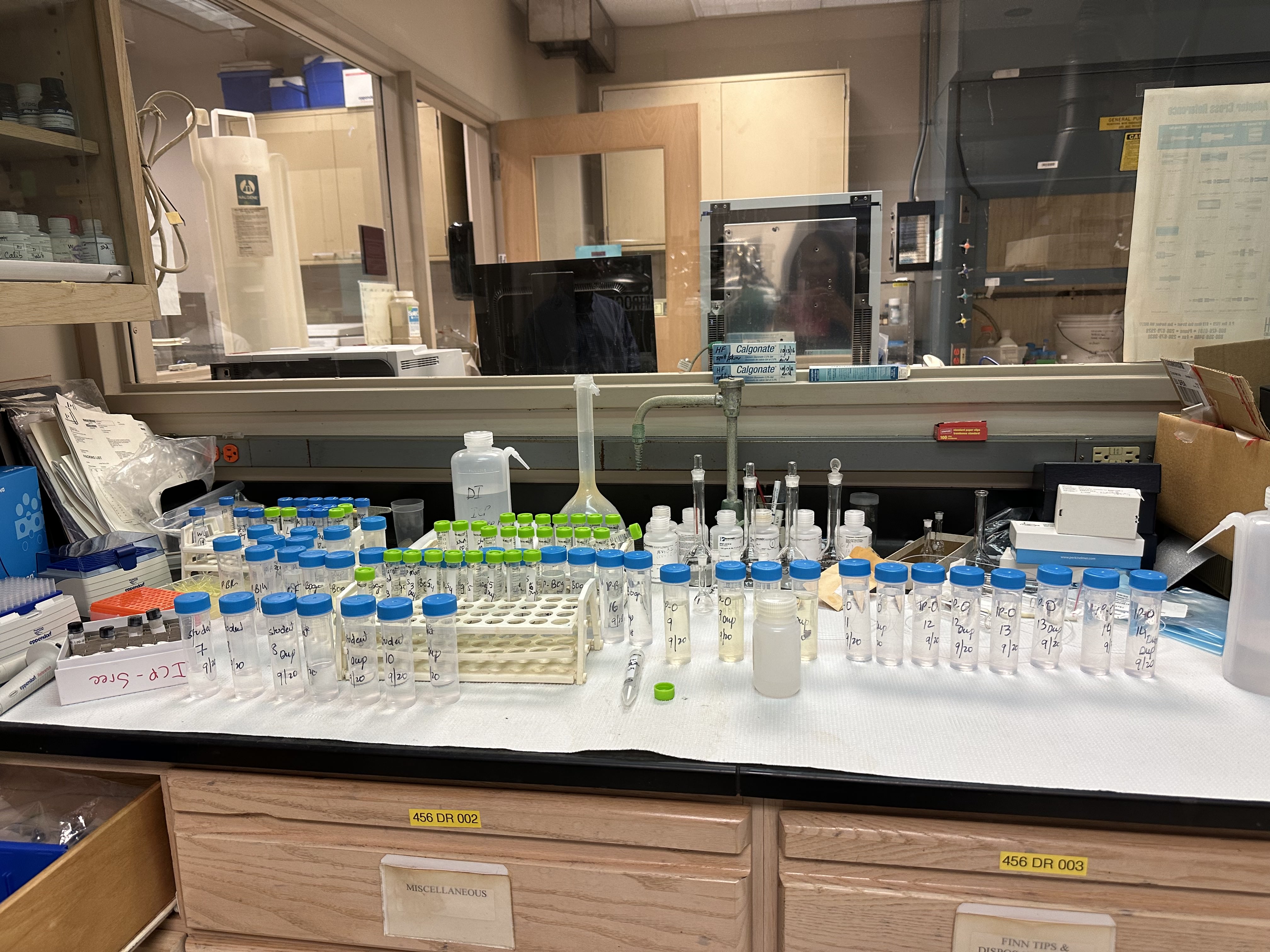

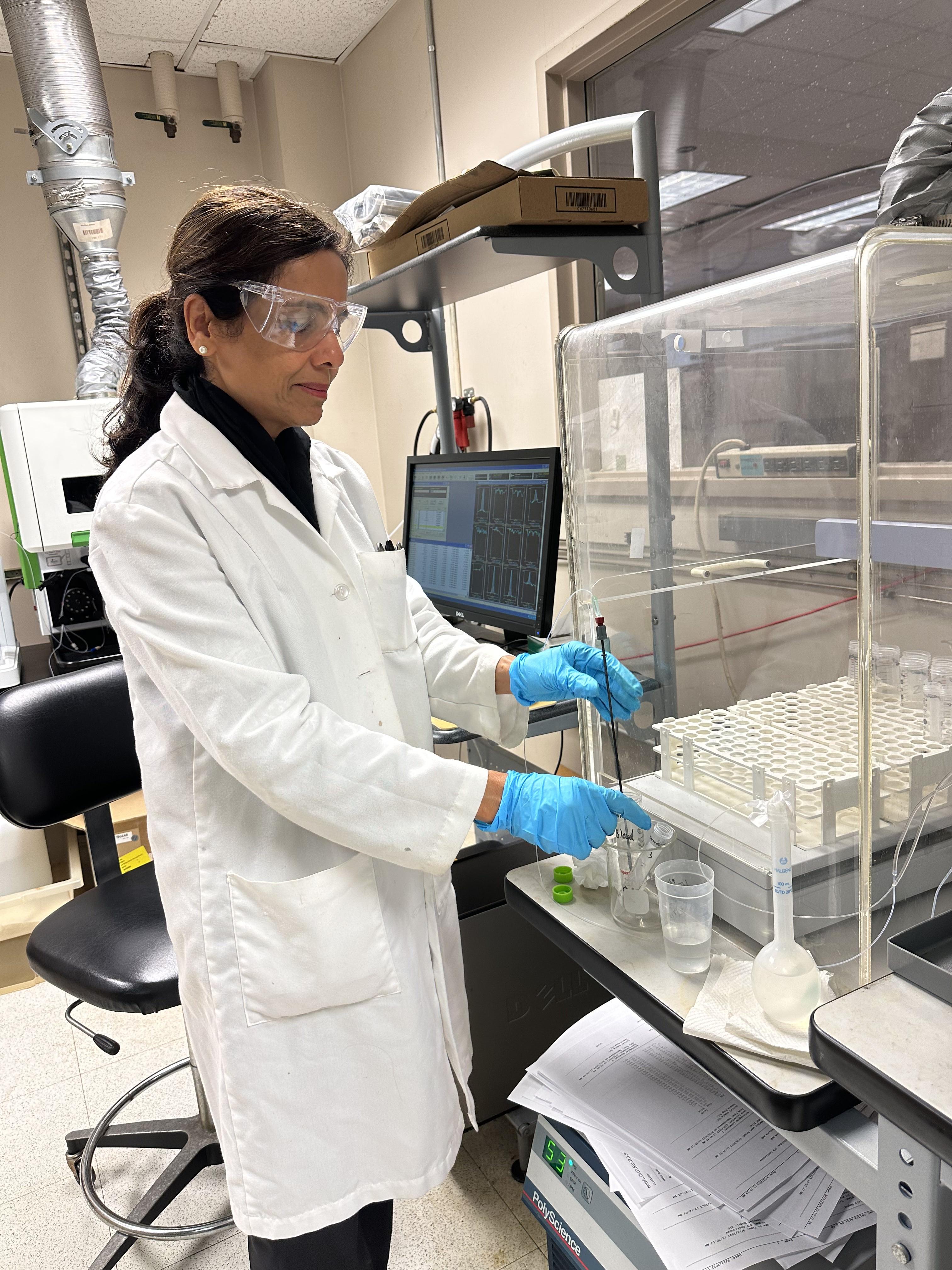

In the first step, inorganic elements in BL are identified by digesting it in a precise mixture of acids and filtering the mixture. The filtrate is introduced into an Inductively Coupled Plasma (ICP) Emission Spectrometer that can identify more than 70 different inorganic elements and compounds like sulfur, potassium, sodium, iron, calcium, etc. The next step involves identifying the proportion of anions like sulfate, chloride, thiosulfate. In this step, BL is diluted to a specific level and analyzed using a method called Capillary Ion Electrophoresis (CIE).

The next step involves analyzing BL for organic substances using two methods – gas chromatography mass spectrometry (GC/MS) and Fourier Transform Infrared Spectrometry (FTIR). For organic substances with a lower molecular weight of less than 600 Daltons (Da), GC/MS is employed where the gas chromatography separates the chemical mixture, and the mass spectrometry identifies each of the components.

The final step is to identify organic substances and polymers with higher molecular weights. For example, lignin is one of the main polymers in BL with a molecular weight higher than 600 Da. FTIR is used for testing during this step. Based on vibrations within each molecule, an FTIR spectrum allows identification of molecular groups within lignin. The equipment then uses a computer to identify the substances by comparing the sample spectrum with a built-in library. The RBI team provides detailed lab reports that is used by the pulp mill to adjust their operating parameters for trouble-free operations.

In addition to the chemical analysis of byproducts like black liquor and other chemical compounds, Rallming Yang’s team also conducts studies on pulping and bleaching, repulping, and fiber characterizations.

Xiaoyan Zeng, Research Scientist at RBI preparing black liquor for identifying anions

Diluted black liquor ready for testing

Tabassum Shah, Research Coordinator at RBI, tests black liquor using ICP Emission Spectrometer

Priya Devarajan || Research Communications Program Manager, RBI

$3M NSF Investment Will Create New Semiconductor, 3D Printing Materials

Oct 20, 2023 — Atlanta, GA

From left, researchers Jason Azoulay, Natalie Stingelin, and H. Jerry Qi have received grants from the National Science Foundation to create advanced materials for semiconductors and 3D printing.

Researchers at Georgia Tech will work to develop new controllable materials for 3D printing, electronics made from plastics, and semiconductors that convert infrared light into electrical signals as part of the National Science Foundation’s (NSF) efforts to create advanced materials.

Altogether, the agency is investing $3 million in the three projects led by faculty members in the George W. Woodruff School of Mechanical Engineering (ME) and the School of Materials Science and Engineering (MSE). Georgia Tech is a contributing partner on a fourth project led by Notre Dame researchers to explore materials that can be switched from an insulator to a metal with an external trigger.

The new awards are part of NSF’s Designing Materials to Revolutionize and Engineer our Future (DMREF) program, which is intended to discover and create advanced materials twice as fast and at a fraction of the cost of traditional research methods.

Read more about the researchers' plans on the College of Engineering website.

Joshua Stewart

College of Engineering

Professor David Sholl Leading New Energy Earthshot Research Center to Stem Climate Change

Oct 18, 2023 — Atlanta, GA

David Sholl, a professor in Georgia Tech's School of Chemical and Biomolecular Engineering and director of Oak Ridge National Laboratory'sTransformational Decarbonization Initiative, is director of the ORNL-led Non-Equilibrium Energy Transfer for Efficient Reactions (NEETER).

David Sholl, a professor in Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE), is leading a new Energy Earthshot Research Center (EERC) at the Department of Energy's Oak Ridge National Laboratory (ORNL) that is focused on developing chemical processes that use sustainable methods instead of burning fossil fuels to radically reduce industrial greenhouse gas emissions to stem climate change and limit the crisis of a rapidly warming planet.

Sholl, who is director of ORNL’s Transformational Decarbonization Initiative, is director of the ORNL-led Non-Equilibrium Energy Transfer for Efficient Reactions (NEETER), which also involves ChBE faculty members Fani Boukouvala and Carsten Sievers as key members.

NEETER is one of two new DoE EERCs involving ChBE faculty; the other (co-led by Professor David Flaherty) is Harnessing Electrostatics for the Conversion of Organics, Water and Air: Driving Redox on Particulate Liquids Earthshot (DROPLETS).

Debaronizing Large-scale Processes

NEETER will coordinate a research team from across the nation focused on replacing bulk heating for chemical processes with electrified means, providing a new way to do chemistry, and decarbonizing large-scale processes in the chemical industry. The Department of Energy has committed $19 million over four years for the center.

“This center is an exciting opportunity to advance innovative methods for performing important chemical reactions with heat derived from electricity instead of burning fossil fuels,” Sholl said. “Our world-class team will combine powerful fundamental insights with leadership-class computing to push forward use of mechanochemistry and resistive heating to achieve chemical outcomes that are simply not possible with traditional heating methods.”

Sholl, who also serves as interim executive director of the University of Tennessee Oak Ridge Innovation Institute, will lead the NEETER effort to harness the expertise of more than 20 co-principal investigators from two other national laboratories and several universities.

In addition to ORNL, other center investigators come from DOE’s SLAC National Accelerator Laboratory at Stanford University and the Princeton Plasma Physics Laboratory, Delaware State University, the Georgia Institute of Technology, Princeton University, the University of Houston, and the University of Maryland.

The scientists, in addition to using their own laboratories, will use DOE Office of Science user facilities, including ORNL’s Oak Ridge Leadership Computing Facility, Spallation Neutron Source, High Flux Isotope Reactor, and Center for Nanophase Materials Sciences. They will also include the beam line at SLAC.

Energy Earthshot Goals

“Our Energy Earthshots are game-changing endeavors to unleash the technologies of the clean energy transition and make them accessible, affordable, and abundant,” said U.S. Secretary of Energy Jennifer M. Granholm. “The Energy Earthshot Research Centers and the related work happening on college campuses around the country will be instrumental in developing the clean energy and decarbonization solutions we need to establish a 100% clean grid and beat climate change.”

NEETER’s proposed research is a radical departure from traditional chemistry and holds promise for transformational breakthroughs in energy-related chemical reactions. The NEETER EERC addresses the DOE’s Industrial Heat Shot announced in 2022, which aims to develop cost-competitive industrial heat decarbonization technologies with at least 85% lower greenhouse gas emissions by 2035. This EERC will employ new kinds of chemical catalysis as one pathway toward electrifying the delivery of process heat.

Industrial heat involves the burning of fossil fuels, which contributes massive amounts of carbon dioxide to the atmosphere. About 40% of those emissions come from chemicals and refining procedures. Because many industrial processes require extremely high energy, decarbonizing these chemical processes via electrification would radically alter the industrial chemical landscape.

Researchers propose two main ways of electrification, Sholl explained. One is through a process called mechanocatalysis, which creates mechanically initiated reactions. Another is Joule heating — using electricity to achieve very rapid temperature increases. The aim is to control chemical reactivity through temperature and pressure, by rapid heating in the Joule heating case, or by mechanical collisions in the case of mechanocatalysis.

NEETER’s mission is “To understand and control spatial and temporal non-equilibrium heat transfer to enable transformational breakthroughs in energy- and atom-efficient endothermic catalytic reactions beyond limitations of thermodynamic and kinetic equilibrium to decarbonize the US chemical industry.”

Said Sholl, “We envision a future where we use renewable electricity to provide heat and produce chemicals without greenhouse gas emissions.”

DROPLETS Earthshot

David Flaherty, a professor in Georgia Tech’s School of Chemical and Biomolecular Engineering, is co-principal investigator of another Energy Earthshot Energy Research Center called Harnessing Electrostatics for the Conversion of Organics, Water and Air: Driving Redox on Particulate Liquids Earthshot (DROPLETS).

The overall objective of DROPLETS is to explore an unconventional, straightforward, and underutilized approach based on microdroplet-enabled redox reactions (which involve the transfer of electrons between substances) towards H2 production (a clean and renewable energy source), CO2 activation (which can help mitigate greenhouse gas emissions), and the synthesis of redox species for long-duration energy storage (LDES).

DROPLETS strives to achieve simplicity and lower the energy input and reactor cost for complex chemical reactions, a key advantage to simultaneously achieve multiple Energy Earthshots, including the Hydrogen Shot, the Long Duration Storage Shot, and the Carbon Negative Shot.

DROPLETS is led by Professor Joaquin Rodriguez Lopez of the University of Illinois, Urbana-Champaign.

David Flaherty, a professor in Georgia Tech's School of Chemical and Biomolecular Engineering

Brad Dixon, braddixon@gatech.edu

New Polymer Membranes, AI Predictions Could Dramatically Reduce Energy, Water Use in Oil Refining

Oct 16, 2023 — Atlanta, GA

A sample of a DUCKY polymer membrane researchers created to perform the initial separation of crude oils using significantly less energy. (Photo: Candler Hobbs)

A new kind of polymer membrane created by researchers at Georgia Tech could reshape how refineries process crude oil, dramatically reducing the energy and water required while extracting even more useful materials.

The so-called DUCKY polymers — more on the unusual name in a minute — are reported Oct. 16 in Nature Materials. And they’re just the beginning for the team of Georgia Tech chemists, chemical engineers, and materials scientists. They also have created artificial intelligence tools to predict the performance of these kinds of polymer membranes, which could accelerate development of new ones.

The implications are stark: the initial separation of crude oil components is responsible for roughly 1% of energy used across the globe. What’s more, the membrane separation technology the researchers are developing could have several uses, from biofuels and biodegradable plastics to pulp and paper products.

“We're establishing concepts here that we can then use with different molecules or polymers, but we apply them to crude oil because that's the most challenging target right now,” said M.G. Finn, professor and James A. Carlos Family Chair in the School of Chemistry and Biochemistry.

Joshua Stewart

College of Engineering

Georgia Tech Interdisciplinary Research Institutes Create Faculty Advisory Council

Oct 02, 2023 — Atlanta, GA

Research faculty at the Georgia Institute of Technology now have their own advocacy group. Since 2022, the Research Faculty Advisory Council (RFAC) has increased research faculty engagement and addressed concerns from researchers in the Interdisciplinary Research Institutes (IRIs), joining similar organizations that address such needs in other colleges.

The group addresses issues such as retention, professional development, recognition, and compensation. Julia Kubanek, vice president for Interdisciplinary Research (VPIR), formed the group after hearing feedback from research faculty and modeled it after a similar council in the College of Sciences.

“This advisory council has helped clarify how we can improve both the status and experience of research faculty on campus,” Kubanek said. “The recommendations they’ve provided and the initiatives they’ve launched are already making a difference.”

The 12 members are nominated from across the IRIs, plus two other interdisciplinary research units supported by the VPIR. These members include:

- Vishwadeep Ahluwalia (Center for Advanced Brain Imaging)

- Michael Chang (Brook Byers Institute for Sustainable Systems)

- Sriram Chockalingam (Institite for Data Engineering and Science)

- Christine Conwell (Strategic Energy Institute)

- Andrew Dugenske (Georgia Tech Manufacturing Institute)

- Ulrika Egertsdotter (Renewable Bioproducts Institute)

- Evan Goldberg (Global Center for Medical Innovation )

- Walter Henderson (Institute for Materials)

- Johannes Leisen (Parker H. Petit Institute for Bioengineering and Bioscience)

- Paul Joseph (Institute for Electronics and Nanotechnology)

- Leanne West (Pediatric Technology Center)

- Clint Zeagler (Institute for People and Technology)

In its first year, RFAC had two co-leads: Andrew Dugenske, the director of the Factory Information Systems Center and a principal research engineer at the Georgia Tech Manufacturing Institute, and Paul Joseph, a principal research scientist and director of External User Programs for Southeastern Nanotechnology Infrastructure Corridor.

“Although the research faculty contribute significantly to the overall growth of Georgia Tech, we remain largely underrepresented, unrecognized, and underemployed because of the lack of suitable platforms to talk about the challenges faced by research faculty colleagues,” Joseph said. “It was not a surprise that the same concerns surfaced and were discovered by the council when we collected input from the research faculty throughout the IRIs on issues that concern and are important to research faculty.”

Although Joseph and Dugenske have completed their terms in their leadership roles, they are satisfied with RFAC’s initial success in creating awareness of research faculty challenges on campus, and initiatives that include a mentorship program with the Research Next team, a Research Faculty Mentoring Network, and efforts in RFAC bylaws creation. Leanne West and Walter Henderson now serve as co-leads.

“It was great for the administration to recognize the many contributions that research faculty make to the Institute and establish a way to improve research faculty job satisfaction and engagement,” Dugenske said. “During the first year of the RFAC, the committee did a great job of gathering issues of importance to research faculty and presenting clear and actionable recommendations to decision-makers.”

Tess Malone, Senior Research Writer/Editor

tess.malone@gatech.edu

Stingelin Elected to European Academy of Sciences

Sep 13, 2023 — Atlanta, GA

Natalie Stingelin, chair of Georgia Tech’s School of Materials Science and Engineering, has been elected to the European Academy of Sciences (EURASC). The honor is bestowed upon the most distinguished European scholars and engineers for their research and contributing to the development of advanced technologies. Each honoree also displays a strong commitment to promoting science and technology in Europe.

Stingelin is recognized for her significant contributions in the broader areas of polymer physics, functional macromolecular materials, and organic electronics and photonics as well as her strong devotion and conviction to generating a notable impact on the wider engineering field as a role model for women in STEM.

Jason Maderer

College of Engineering

MSE Professor Blair Brettmann and CHBE student Alexa Dobbs Spend Summer at LLNL Exploring Materials Processing and Manufacturing

Sep 21, 2023 — Atlanta, GA

MSE professor Blair Brettmann (left) and CHBE doctoral student Alexa Dobbs (right) spent the summer at LLNL, collaborating with LLNL experts to explore techniques that can help them with their materials science research. Photo: Garry McLeod/LLNL.

MSE Professor Blair Brettmann and CHBE doctoral student Alexa Dobbs decided to spend a summer at Lawrence Livermore National Laboratory (LLNL) to collaborate with the Lab’s materials science experts and learn more about LLNL’s experimental resources. During Brettmann’s faculty mini-sabbatical, she collaborated with researchers from LLNL’s Energetic Materials Center to refine material manufacturing techniques.

According to LLNL materials scientist Kyle Sullivan, who sponsored Brettmann’s mini-sabbatical, she helped his team take a fresh look at their methodology, enabling them to identify ways to streamline a highly complex process.

“Many of our material development activities start with multi-faceted problems,” Sullivan said. “We were eager to draw from Blair’s experience in pharmaceutical manufacturing to help us identify an efficient methodology to apply to our research.”

Brettmann’s research focuses on material processing, including how a material’s properties influence the optimal processing approach, as well as how novel processing techniques can be used to develop materials with the features needed for specific applications. Her goal is to better understand options for real-time monitoring of material processing, including effective data collection tools, as well as knowing which experimental data would be beneficial to analyze. As she heads back to Georgia Tech to start another academic year, Brettmann is hoping that the insight she gained during her mini-sabbatical will help her research team as they test new analytical techniques for their material formulation experiments.

Dobbs spent her summer at LLNL investigating material formulation techniques. She helped design and conduct experiments that explored ways to optimize material mixing and she developed a new process for analyzing experimental data. During her internship, Dobbs met with LLNL experts in materials processing and advanced manufacturing, who helped her frame her experiments.

“It was great to expand my understanding of the entire manufacturing process and learn about key challenges in the field," Dobbs said. “The opportunity to spend time with energetics experts was one of the highlights of my internship experience.”

2023 RBI Seed Funding Lunch and Learn

2023 RBI Seed Funding Lunch and Learn - A great opportunity for Georgia Tech Faculty

Please join the Renewable Bioproducts Institute for lunch, meet our recently expanded industrial members, and learn about changes to the RBI fellowship funding program. Faculty will learn how to apply for seed grants, and can discuss potential project ideas, connect with potential collaborators, and gain valuable feedback from industry and RBI leadership.

2023 RBI Spring Workshop Experience From a Student's Perspective - Part 3

Sep 21, 2023 — Atlanta, GA

Erin Phillips at the 2033 RBI Spring Workshop

This is part three of the student experiences series. Erin Phillips, rising fourth-year Ph.D. candidate in chemistry and biochemisty shares her experience from the 2023 RBI Spring Workshop on "Innovations in Packaging and Circular Economy."

Tell us about yourself.

My name is Erin Phillips, and I am a rising fourth-year Ph.D. student here at Georgia Tech. I graduated with my bachelor's from Christopher Newport University in Newport News, Virginia, in 2020. I am a student in the School of Chemistry and Biochemistry, but I am co-advised by Carsten Sievers in the School of Chemical and Biomolecular Engineering and Marta Hatzell in the George W. Woodruff School of Mechanical Engineering. The title for my thesis project is "Mechanochemical Depolymerization of Lignin and Lignin Model Compounds." I am currently writing a JACS Communication about the cleavage of the lignin model compound benzyl phenyl ether, which represents the B-O-4 bond found within lignin.

How was your experience at the RBI workshop?

I thought the workshop was fantastic! I really enjoyed the interdisciplinary focus of the event, which allowed for greater networking opportunities between departments.

What was your main takeaway from the poster session?

During the poster session, it was great to see what other PSE (Paper Science and Engineering) fellows were currently working on. We often all take classes together and pass each other in RBI, but it was nice to actually see everyone's work laid out and visually represented. I also enjoyed talking with a few people from the industry about their expectations in terms of hiring after graduate school and what a realistic position in an industry setting would entail.

What more would you like to see in future events at the Renewable Bioproducts Institute?

I think the greatest thing RBI can do is to continue to allow for PSE fellows to build contacts that we may not normally have access to during our day-to-day lives in RBI. Many of us want to continue in our field of research after leaving Georgia Tech, so events like the RBI workshop are a great experience to connect with others who share our interest and could help provide opportunities after completing the program.

Priya Devarajan || RBI Communications Program Manager