2023 Southeast Regional Clinical and Translational Science Conference

Registration Required - Click HERE

Join the Georgia CTSA at Callaway Resort and Gardens as they bring together researchers from across the region to present the best new health-related preclinical, clinical, implementation, and population-based research and build collaborative relationships. Hosted by the Georgia CTSA, with participation from:

Materials Characterization Facility Open House

Materials Characterization Facility Open House

Monday, November 14

10:00 a.m. - 1:00 p.m. - Electron Microscopy

2:00 p.m. - 5:00 p.m. - X-Ray analysis

Tuesday, November 15

10:00 a.m. - 1:00 p.m. - Optical & X-ray Spectroscopy

2:00 p.m. - 5:00 p.m. - Open session

Vapor Cells for Quantum Sensors

Vapor cells for quantum sensors

Blowin' in the Wind

Oct 19, 2022 — Atlanta, GA

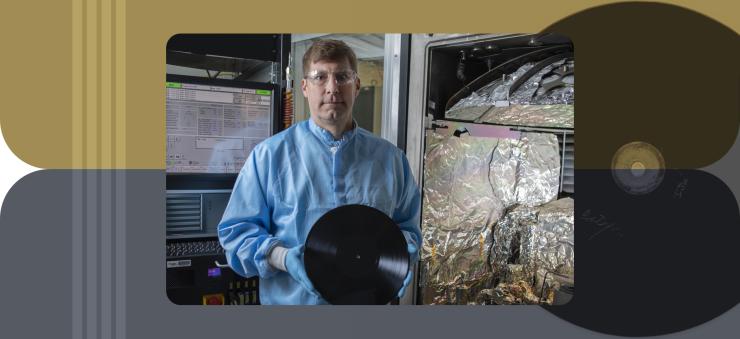

Jud Ready, a GTRI principal research engineer, worked with a team of artists and recording engineers to boost the quality of analog music reproduction through a new surface coating that both improves sound quality and prevents wear. Credit: Christopher Moore

As music distribution technology shifted from analog vinyl records to digital compact discs (CDs) and then to streaming files, the sound quality took a substantial hit – along with the monetary value of the musical consumer product.

Now, as the vinyl format is enjoying a comeback, materials scientists at the Georgia Tech Research Institute (GTRI) have worked with a team of artists and recording engineers to boost the quality of analog music reproduction through a new surface coating that both improves sound quality and prevents wear. The patented technology led to the creation of a one-of-a-kind Bob Dylan record that recently brought $1.8 million at a Christie’s auction.

A First for a New Generation of Discs

The studio recording of Dylan’s 1963 classic “Blowin’ in the Wind” is the first of a new generation of unique archival records with spectacular sound quality and the capacity for a thousand plays (or more) without deterioration. For musician and producer T Bone Burnett, the goal of the effort was to provide musical artists with a new medium – and an opportunity to set the value of their work themselves.

“Recording artists have had the value of what we do determined for us under the shorter and shorter-term technologies of mass production and distribution by organizations, governments, distributors, streamers, and others, but we have not had a way to find the value of an individual work of art,” said Burnett, a long-time Dylan collaborator who played guitar on the recording. “If we are able to help establish a music space in the fine arts through the making of these archival discs, musicians will be able to find real value for their work.”

Nanometer-Scale Coatings Improve Quality

The new record format, which Burnett has dubbed an “Ionic Original,” was made possible by a unique coating of sapphire and quartz applied to a layer of nitrocellulose on an aluminum disc. The coating was developed with help from GTRI materials scientists Jud Ready and Brent Wagner.

“We helped them develop a way to put a hard oxide coating on top of the nitrocellulose lacquer to protect it during play,” said Ready, a GTRI principal research engineer and deputy director of Georgia Tech’s Institute for Materials. “That includes silica (SiO2), better known as quartz, and alumina (Al2O3), which is known as sapphire. With other ingredients and variables, it’s a gradient designed to produce the best sound quality and resist the wear that would otherwise happen to the nitrocellulose acetate.”

A hard coating is needed because the stylus “needle” used to play the record on a conventional turntable can be made of diamond, which is even harder than quartz or sapphire. Playing a traditional vinyl record causes abrasion in the much softer grooves where the music is stored, causing wear that degrades the sound quality over time and also creates annoying pops and noise – issues that led to adoption of compact discs which are played with a non-contact optical reader.

The Analog Advantage

But digital formats – CDs and streaming files – provide listeners a digitally sampled version of the original analog sound rather than more fully reproducing what was created by the musicians. Though most consumers won’t notice, the difference can be heard – which helps account for the renaissance of analog records.

“Analog music travels in actual waves – not sampled and simulated – and sounds more resonant, deeper, and truer,” Burnett explained. “Analog records more atmosphere. It is closer to the human. An Ionic Original is the equivalent of a painting, hand-made and retouched by the artist. A digital stream is the equivalent of seeing a copy of a photograph of a painting.”

Subjecting the Research to the Turntable Test

In 2013, Ready and Wagner worked with Burnett and recording engineer Barak Moffitt to develop the coating technique, which was patented. The patent is now owned by Ionic Recording Company LLC, which bought it from Georgia Tech. Separate from the original work that led to the patent, Ready more recently worked as a private consultant with Ionic to support refining the new process and identifying a company that could coat the record.

“The issues were in the thin film coatings – the time, the density of the coating, the ratio between the two elements – and the pre-cleaning process before the coating was put down,” Ready explained.

Ahead of the quartz-sapphire coating process, production of the record proceeded much like any other analog record. Dylan recorded the song in 2021; it was mixed in Los Angeles and Nashville, and finally mastered in Memphis by Jeff Powell, one of the world’s top vinyl cutting experts.

“When an artist like Bob Dylan, a producer like T Bone Burnett and a recording engineer like Mike Piersante went into a project like this, they knew the desired result was a pristine vinyl master lacquer that would go through the Ionic coating process and sound as good or better than any vinyl record ever made even after 1,000 plays,” said Powell.

Several 10-inch-diameter discs were made and compared by Piersante, who graded them all on a scale of zero to 10. The best one was sent to Virginia-based Blue Ridge Optics for application of the thin-film coating. After that, the disc flew by private jet to California, where it was analyzed acoustically and presented to the media. Finally, it went on to London for the Christie’s auction.

An Eye-Opening Experience for a Materials Engineer

Ready’s bread-and-butter research involves thin-film coatings, but this is his first foray into the entertainment industry.

“We would normally put these down for optical coatings and to protect microelectronic devices,” Ready explained. “It’s a hundred nanometers or so of silica and alumina – a nanometer is a billionth of a meter – to create the scratch-resistant coating. At GTRI, we apply these coatings with a commercial-scale tool that is commonly used to put anti-reflective coatings on eyeglasses and on equipment used in space.”

Working as a consultant, Ready visited Burnett’s studio to compare the sound of the same song played from magnetic tape, vinyl, CD and finally, streaming files.

“The amount of resolution that goes away is incredible,” he said. “Whole instruments disappear. You could hear the faintest of different sounds on the tape and vinyl – but they were gone. There are ways that the CD recording is taking the sinusoidal analog waves and breaking them into lots of little rectangles. No matter how skinny you make the rectangle, you are always going to be losing some sound or adding noise.”

“Blowin’ in the Wind” Could Make New Waves

The 2021 Bob Dylan recording of “Blowin’ in the Wind” was just the second ever to be made in the studio. Written by the artist in 1962 and released on The Freewheelin’ Bob Dylan in 1963, it is a protest song that asks a series of questions about peace, war, and freedom. The song has been inducted into the Grammy Hall of Fame and, in 2004, was ranked 14th on Rolling Stone magazine's list of the "500 Greatest Songs of All Time."

What’s next for the process? Burnett believes the technique may generate interest among music archivists who may want to store recordings protected from wear. He promises there will be more one-of-a-kind records, including “several” additional Dylan cuts.

“We are speaking with interested people about private sales, and with other artists about making further Ionic discs,” he said. “Perhaps there will be other auctions. We remain open to seeing where this path leads.”

Writer: John Toon

GTRI Communications

Georgia Tech Research Institute

Atlanta, Georgia USA

About GTRI: The Georgia Tech Research Institute (GTRI) is the nonprofit, applied research division of the Georgia Institute of Technology (Georgia Tech). Founded in 1934 as the Engineering Experiment Station, GTRI has grown to more than 2,800 employees, supporting eight laboratories in over 20 locations around the country and performing more than $700 million of problem-solving research annually for government and industry. GTRI's renowned researchers combine science, engineering, economics, policy, and technical expertise to solve complex problems for the U.S. federal government, the state, and industry. For more information, please visit www.gtri.gatech.edu.

GTRI researchers used this equipment to apply wear-resistant coatings. Shown is Jud Ready holding an acetate of the type used in the research. Credit: Christopher Moore

(Interim) Director of Communications

Michelle Gowdy

Michelle.Gowdy@gtri.gatech.edu

404-407-8060

Datta Receives VLSI Technology and Circuits Test of Time Award

Oct 18, 2022 — Atlanta, GA

Suman Datta, Joseph M. Pettit Chair and a Georgia Research Alliance (GRA) Eminent Scholar

Suman Datta has received the Test of Time Award at the 2022 IEEE Symposium on VLSI Technology and Circuits. Datta is the Joseph M. Pettit Chair in Advanced Computing in the Georgia Tech School of Electrical and Computer Engineering (ECE) and a Georgia Research Alliance Eminent Scholar.

Datta, who holds a joint appointment with the School of Materials Science and Engineering, was honored this year along with his co-authors and former colleagues at Intel Corporation for his 2006 research, “Tri-Gate Transistor Architecture with High-k Gate Dielectrics, Metal Gates and Strain Engineering.” True to its name, the Test of Time Award recognizes papers that have established their significance in history by standing the test of time. The goal of the award is to honor impactful papers and promote their recognition in the Symposia’s community.

As transistor gets smaller, it gets harder to switch off the transistor effectively. In response, Datta and his former Intel colleagues formulated the Tri-Gate transistor technology that was first introduced commercially at the 22-nm technology node. The transistor architecture has scaled to the 5-nm node and remains the workhorse of all leading-edge logic technology.

The research was the first experimental demonstration of high-performance NMOS and PMOS Tri-gate transistors in which the channel strain, high-k gate dielectric, gate electrode work functions, epitaxial source-drain regions were co-optimized together with the fin dimensions (width and height) and the fin shape (trapezoidal versus rectangular). The paper illustrated how to combine the electrostatic benefit of the fully-depleted nonplanar transistor structure with high-permittivity gate dielectric, work-function engineered metal gate electrodes and high- strain-engineered high-mobility channel to demonstrate high-performance CMOS transistors.

In addition to receiving the Test of Time Award at the symposium, Datta organized a short course on Monolithic and Heterogenous Integration and Advances in Application-Specific Computing Systems and Technologies. His research group presented three papers at the symposium on A Thousand State Superlattice Ferroelectric Field Effect Transistor Analog Weight Cell (with Professor Shimeng Yu); BEOL Compatible Ferroelectric Routers for Run-time Reconfigurable Compute-in-Memory Accelerators (with Professor Shimeng Yu) and Multi-bit per-cell 1T SiGe Floating Body RAM for Cache Memory in Cryogenic Computing (with Professor Arijit Raychowdhury).

Now in it’s 42nd year, the IEEE Symposium on VLSI Technology and Circuits is known as the microelectronics industry’s premiere international conference integrating technology, circuits, and systems. The 2022 symposium convened this year in Honolulu, Hawaii.

Dan Watson

dwatson@ece.gatech.edu

Engel Recognized for Semiconductor Research at ICMBE

Oct 13, 2022 — Atlanta, GA

Zachary, a Ph.D. candidate in the Georgia Tech School of Electrical and Computer Engineering

Zachary Engel has won the Best Student Oral Prize at the 2022 International Conference on Molecular Beam Epitaxy (ICMBE). Engel is a Ph.D. candidate in the Georgia Tech School of Electrical and Computer Engineering (ECE) and is part of ECE’s Advanced Semiconductor Technology Facility (ASTF) directed by Professor Alan Doolittle.

ICMBE recognized Engel for the quality of his work and presentation excellence on "Demonstration of Sc0.2Al0.8N HEMT structures with a sheet resistance of 150 Ω/□ and a sheet charge of 5.9x1013 cm-2 with phase pure, metal rich growth.”

The research presents new semiconductor chemistries that allow for improved semiconductor quality as demonstrated by a record sheet charge and channel resistance in a next generation replacement for the current champion of power and RF transistors, AlGaN/GaN transistors. This new device will allow 2.5 times higher current than present technologies. In principle, it can be integrated with ASTF’s groundbreaking aluminum nitride-based semiconductor, which previous demonstrations have shown to be the largest voltage semiconductor ever created.

This year’s ICMBE was held in Sheffield, United Kingdom from September 4-9. The conference began in 1978 in Paris, France and provides a prominent international forum for reporting new developments in the areas of fundamental and applied molecular beam epitaxy research, including advances in the technique, synthesis of new materials, discovery of new physical properties, formation of novel heterostructures, and the development of innovative devices.

Dan Watson

dwatson@ece.gatech.edu

ECE Panel Discussion - Hardware Research and Education

Hardware Research and Education

Date: Thursday, October 20, 2022

Time: 2:30 p.m. - 4:00 p.m.

Location: Marcus Nanotechnology Building - Atrium

Featuring:

-

Roland Sperlich

Vice President and General Manager for Interface Products

Texas Instruments -

Todd Younkin

President and CEO

Semiconductor Research Corporation

Moderated by Dr. Muhannad Bakir, Dan Fielder Professor

UpNano NanoOne Seminar

UpNano NanoOne Seminar

Join us to learn about the NanoOne, the fastest high-resolution 3D printing system on the market.

UpNano manufactures and sells high resolution 3D printers under the NanoOne platform which are capable of printing parts with a wide range of volumes (100 – 1012 mm3) at unmatched speed.

Kwong using NIH Director's Pioneer Award to Develop Living Biosensors

Oct 05, 2022 — Atlanta, GA

Gabe Kwong won the NIH Director's Pioneer Award.

Some cancers have a long and deadly memory. Years or decades after the disease has been beaten into remission, cancer cells that weren’t killed by initial treatment may be lying dormant at metastatic sites, like the bone marrow, until they reawaken with malignant intent.

Gabe Kwong wants to build living sentinels to detect those dormant and potentially deadly disseminated tumor cells (DTCs) before the cancer can recur. It’s an ambitious and groundbreaking idea from a researcher whose lab has developed a reputation for innovative work, and it’s earned Kwong a 2022 Director’s Pioneer Award from the National Institutes of Health (NIH).

“I’m extremely humbled, and grateful for what this means for the lab,” said Kwong, associate professor in the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory University. “This is a peer-reviewed honor, and it tells us that the field recognizes that our work over the past 10 years has been impactful and worth investing in.”

The Pioneer Awards support highly creative researchers with potentially transformative ideas. The largest grant in the NIH’s High-Risk, High-Reward Research program, the award will provide Kwong $5.5 million over the next five years. This is the first time a Georgia Tech or Emory research has received funding through the program. And it’s Kwong’s second high-risk project funded: He won the NIH Director’s New Innovator Award for early career scientists in 2016.

According to the NIH, proposed pioneering work must be high-impact and “reflect ideas that are substantially different” from the researcher’s current program. Kwong’s lab has been focused on engineering synthetic sensors until now. With this project, he’s shifting to reengineering living cells.

“For years, we’ve been designing ultra-sensitive sensors to detect cancer or the response to immunotherapy drugs. They function as sentinels and report on sites of disease by producing a signal that can be detected from a biofluid such as urine,” he said. “They’ve been inorganic probes that don’t have a memory or know how to think. Our goal is to develop a living sensor — immune cells that can traffic through the body and act as a long-lived pool of sentinels.”

Kwong is driven by the potential threat of cancer dormancy. Many cells leave the primary tumor and enter the body’s circulation. Called circulation tumor cells, or CTCs, they are typically short-lived and don’t lead to metastasis. Sometimes, however, a few of these cells may find their way to a distant organ and hide there, despite seemingly successful cancer treatment. These cells can wait for years, or even decades, before reawakening. So, patients with no evidence of disease could harbor dormant cancer and remain at risk of metastatic relapse for the rest of their lives.

“Currently, there is no good way to monitor these dormant cells or their reawakening,” Kwong said. “But we are living in an entirely new era of medicine and cancer immunotherapy where we can design T cells as living medicines. We see this as an opportunity to not only build a future where immune cells are engineered as therapies, but also as living sensors.”

The idea is to use the same T cells that are grafted into a patient as cancer-fighters as lifelong sensors that are continuously on the lookout for future disease. If Kwong and his team are successful, he said the technological breakthroughs could lead to new about how and when dormant cells reawaken.

“Once we figure out how to engineer these cells, we’ll likely transition to a phase where we’re talking more about earlier detection and preventative medicine,” he said. “Our new drugs are already working much, much better than before. Imagine if we can keep the cancer from coming back for years and years and intervene at the earliest stages of recurrence. That’s the high reward.”

Enabling Miniaturization with Micro 3D Printing

The trend of miniaturization is gaining momentum, as the demand for smaller and smaller parts for consumer electronics, medical devices, robotics, and life sciences grows. One of the new frontiers in Additive Manufacturing (AM) is the production of high-resolution, high-accuracy microstructures for industrial applications. These parts are not only difficult to prototype using existing 3D printers, but they are also often much more expensive and complicated to manufacture.