Neu's research involves the understanding and prediction of the fatigue behavior of materials and closely related topics, typically when the material must resist degradation and failure in harsh environments. Specifically, he has published in areas involving thermomechanical fatigue, fretting fatigue, creep and environmental effects, viscoplastic deformation and damage development, and related constitutive and finite-element modeling with a particular emphasis on the role of the materials microstructure on the physical deformation and degradation processes. He has investigated a broad range of structural materials including steels, titanium alloys, nickel-base superalloys, metal matrix composites, molybdenum alloys, high entropy alloys, medical device materials, and solder alloys used in electronic packaging. His research has widespread applications in aerospace, surface transportation, power generation, machinery components, medical devices, and electronic packaging. His work involves the prediction of the long-term reliability of components operating in extreme environments such as the hot section of a gas turbine system for propulsion or energy generation. His research is funded by some of these industries as well as government funding agencies.

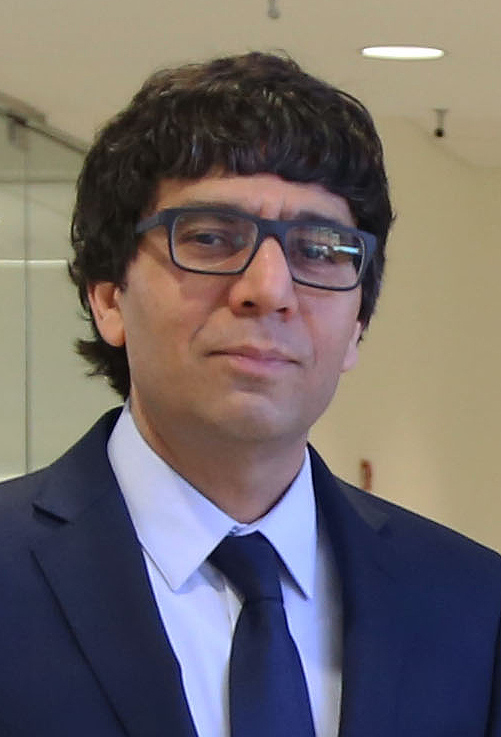

Professor, School of Materials Science and Engineering, Woodruff School of Mechanical Engineering

Additional Research

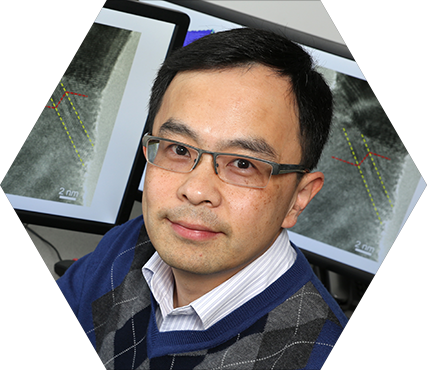

Nanomaterials; micro and nanomechanics; Thermoelectric Materials; fracture and fatigue