Researchers 3D Print First High-Performance Nanostructured Alloy That’s Both Ultrastrong and Ductile

Aug 03, 2022 — Atlanta, GA

A strong and ductile high-entropy alloy is made from additive manufacturing, and it exhibits a hierarchical microstructure over a wide range of length scales. (Image credit: Thomas Voisin).

A team of researchers at the University of Massachusetts Amherst and the Georgia Institute of Technology has 3D printed a dual-phase, nanostructured high-entropy alloy that exceeds the strength and ductility of other state-of-the-art additively manufactured materials, which could lead to higher-performance components for applications in aerospace, medicine, energy and transportation. The research, led by Wen Chen, assistant professor of mechanical and industrial engineering at UMass, and Ting Zhu, professor of mechanical engineering at Georgia Tech, was published in the August issue of the journal Nature.

Over the past 15 years, high entropy alloys (HEAs) have become increasingly popular as a new paradigm in materials science. Comprised of five or more elements in near-equal proportions, they offer the ability to create a near-infinite number of unique combinations for alloy design. Traditional alloys, such as brass, carbon steel, stainless steel and bronze, contain a primary element combined with one or more trace elements.

Additive manufacturing, also called 3D printing, has recently emerged as a powerful approach of material development. The laser-based 3D printing can produce large temperature gradients and high cooling rates that are not readily accessible by conventional routes. However, “the potential of harnessing the combined benefits of additive manufacturing and HEAs for achieving novel properties remains largely unexplored,” says Zhu.

Chen and his team in the Multiscale Materials and Manufacturing Laboratory combined an HEA with a state-of-the-art 3D printing technique called laser powder bed fusion to develop new materials with unprecedented properties. Because the process causes materials to melt and solidify very rapidly as compared to traditional metallurgy, “you get a very different microstructure that is far-from-equilibrium” on the components created, Chen says. This microstructure looks like a net and is made of alternating layers known as face-centered cubic (FCC) and body-centered cubic (BCC) nanolamellar structures embedded in microscale eutectic colonies with random orientations. The hierarchical nanostructured HEA enables co-operative deformation of the two phases.

“This unusual microstructure’s atomic rearrangement gives rise to ultrahigh strength as well as enhanced ductility, which is uncommon, because usually strong materials tend to be brittle,” Chen says. Compared to conventional metal casting, “we got almost triple the strength and not only didn’t lose ductility, but actually increased it simultaneously,” he says. “For many applications, a combination of strength and ductility is key. Our findings are original and exciting for materials science and engineering alike.”

“The ability to produce strong and ductile HEAs means that these 3D printed materials are more robust in resisting applied deformation, which is important for lightweight structural design for enhanced mechanical efficiency and energy saving,” says Jie Ren, Chen’s Ph.D. student and first author of the paper.

Zhu’s group at Georgia Tech led the computational modeling for the research. He developed dual-phase crystal plasticity computational models to understand the mechanistic roles played by both the FCC and BCC nanolamellae and how they work together to give the material added strength and ductility.

“Our simulation results show the surprisingly high strength yet high hardening responses in the BCC nanolamellae, which are pivotal for achieving the outstanding strength-ductility synergy of our alloy. This mechanistic understanding provides an important basis for guiding the future development of 3D printed HEAs with exceptional mechanical properties,” Zhu says.

In addition, 3D printing offers a powerful tool to make geometrically complex and customized parts. In the future, harnessing 3D printing technology and the vast alloy design space of HEAs opens ample opportunities for the direct production of end-use components for biomedical and aerospace applications.

Additional research partners on the paper include Texas A&M University, the University of California Los Angeles, Rice University, and Oak Ridge and Lawrence Livermore national laboratories.

Story by Melinda Rose, Associate News Editor at UMass Amherst.

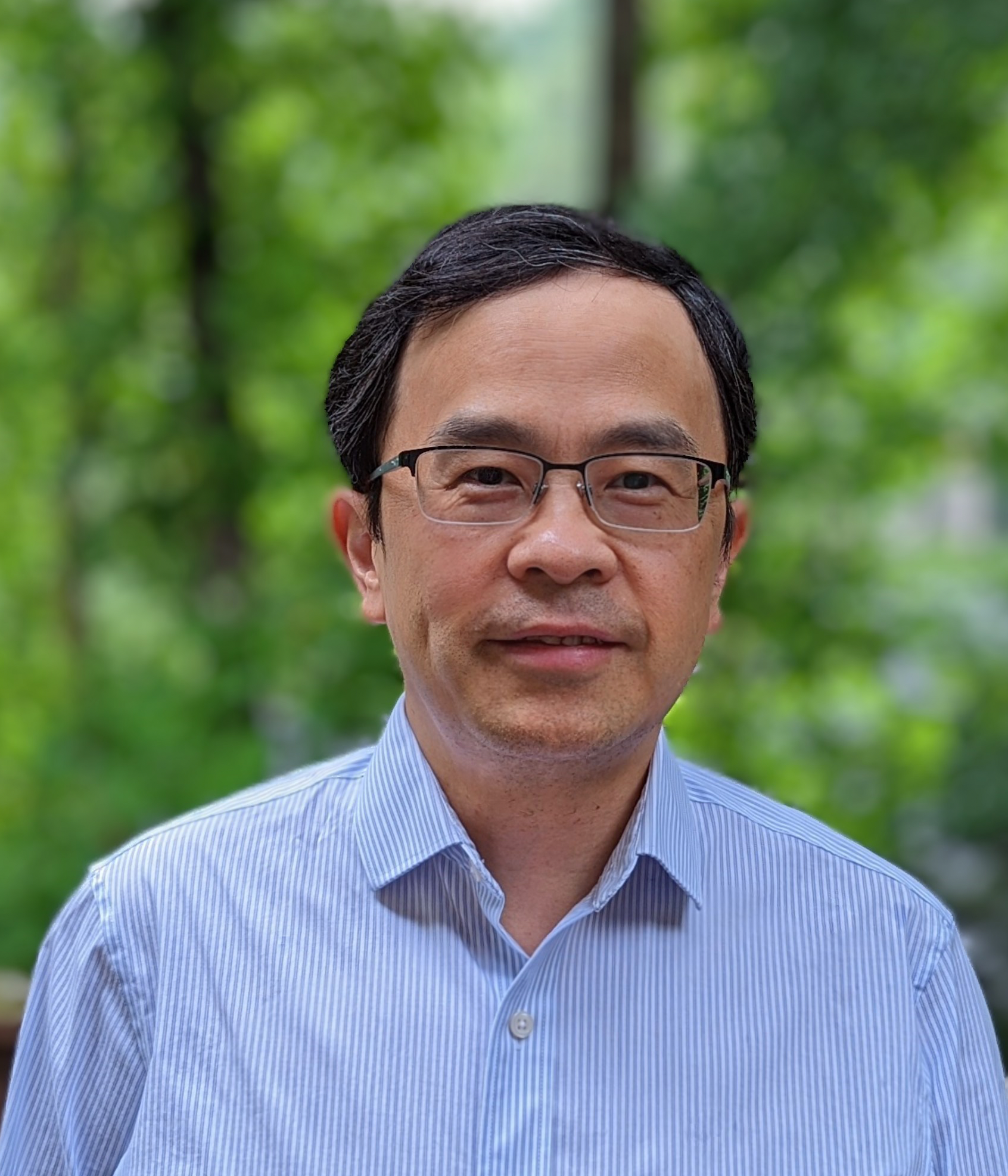

Ting Zhu, Woodruff Professor in the George W. Woodruff School of Mechanical Engineering, Georgia Institute of Technology

Catherine Barzler, Senior Research Writer/Editor

Georgia Tech Faculty and Students Win Awards, Present Research at Design Automation Conference

Jul 26, 2022 — Atlanta, GA

Members of the Georgia Tech School of Electrical and Computer were well-represented at the 59th Design Automation Conference (DAC), a premier event devoted to the design and design automation of electronic chips and systems, was held in San Francisco on July 10-14.

The 59th Design Automation Conference (DAC), a premier event devoted to the design and design automation of electronic chips and systems, was held in San Francisco on July 10-14. The conference offers training, education, exhibits, and networking opportunities for designers, researchers, tool developers and vendors. It is sponsored by the Association for Computing Machinery (ACM) and the Institute of Electrical and Electronics Engineers (IEEE), and is supported by ACM's Special Interest Group on Design Automation (SIGDA) and IEEE's Council on Electronic Design Automation (CEDA).

In the span of five days, DAC provided over 300 technical presentations and sessions that were selected by a committee of electronic design and university research experts offering information on recent developments and trends, management practices and new products, methodologies, and technologies in the electronics industry.

“DAC brings together researchers across the computing stack — technology, circuits, design-automation and computer architecture — enabling a confluence of ideas and cross-stack research," said associate professor Tushar Krishna in the Georgia Tech School of Electrical and Computer Engineering. “It provides a multitude of opportunities for researchers, students, and industry experts to collaborate and influence tomorrow’s innovations, making it a highly exciting and effective conference.”

Faculty members and students in ECE were presented with multiple awards and participated in research talks and technical sessions. ECE’s DAC awards and contributions are listed below:

Awards:

- Professor Sung Kyu Lim and his students Bon Woong Ku (currently at Synopsys) and Kyungwook Chang (currently at Sungkyunkwan University) received the 2022 Donald O. Pederson Best Paper Award for their paper “Compact-2D: A Physical Design Methodology to Build Two-Tier Gate-Level 3D ICs” published in IEEE TCAD.”

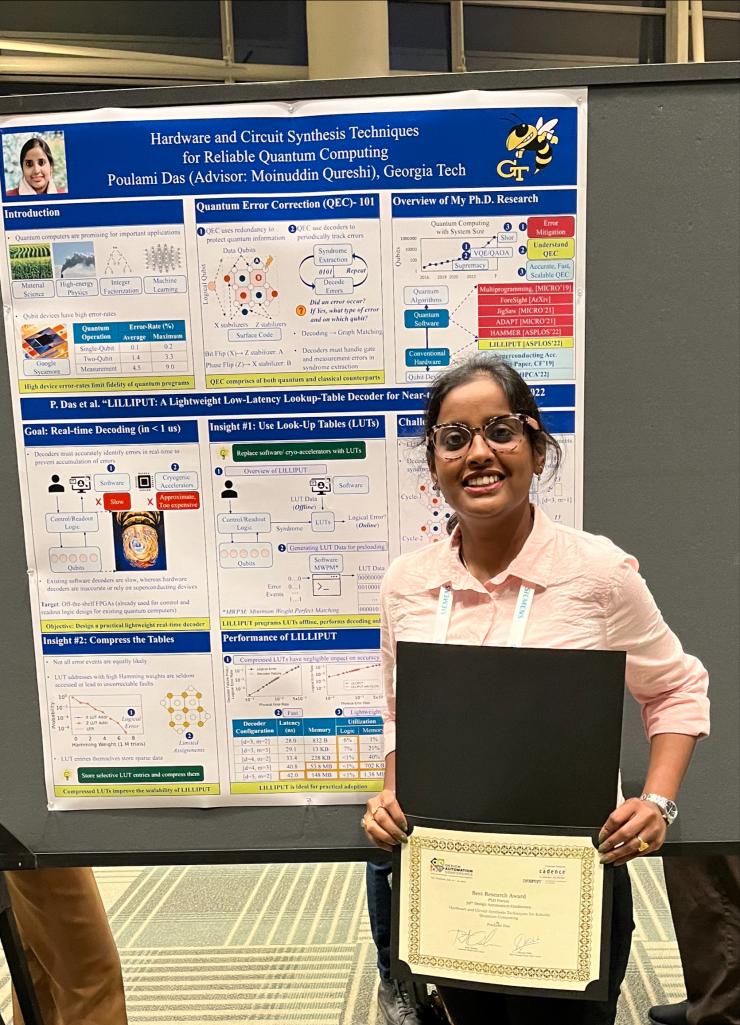

- Ph.D. candidate Poulami Das (supervised by professor Moin Qureshi) won the “Best Research Award” during the Ph.D. Forum.

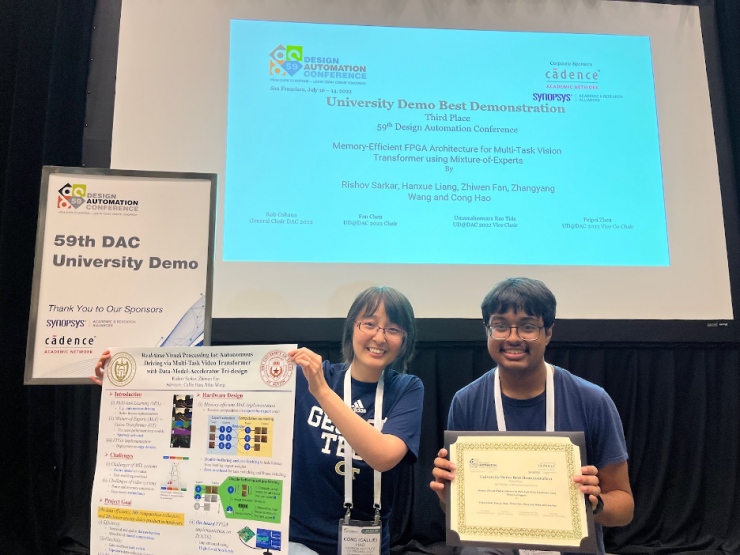

- Ph.D. candidate Rishov Sarkar (supervised by assistant professor Callie Hao) won the third place in the “University Demo Best Demonstration.”

- Ph.D. candidates Foroozan Karimzadeh (supervised by ECE chair Arijit Raychowdhury), Zishen Wan (supervised by Raychowdhury), and Anurag Kar (supervised by professor Hyesoon Kim in Tech’s School of Computer Science) were named 2022 DAC Young Fellows and presented on their respective research during the DAC Young Fellows Program workshop.

Engineering Talks, Tutorials, Workshops, Panels

- Hao gave an invited talk entitled, “3U-EdgeAI: Ultra-Low Memory Training, Ultra-Low Bitwidth Quantization, and Ultra-Low Latency Acceleration” during the Fifth International Workshop on Design Automation for Cyber-Physical Systems (DACPS).”

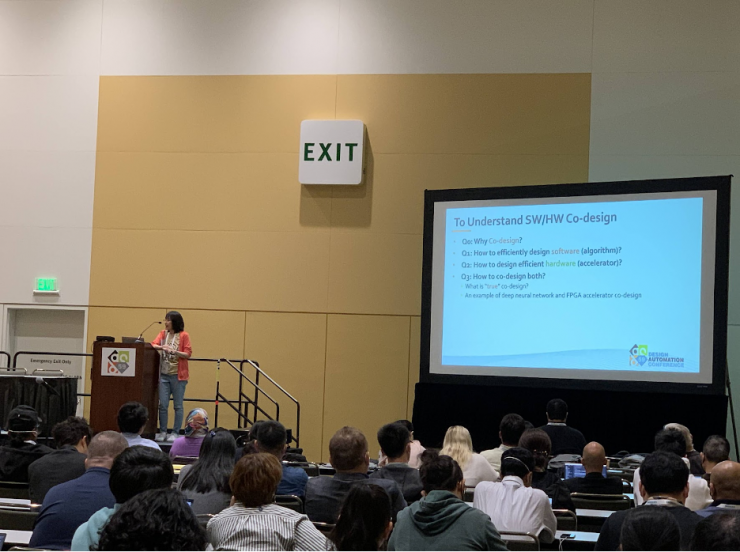

Hao, along with Hyoukun Kwon (a recent Ph.D. graduate supervised by Krishna and now at Meta), presented the tutorial “A Journey to SW/HW Co-design in Machine Learning: Fundamental, Advancement, and Application.” They presented twice on the same day due to tutorial’s popularity.

Hao was also the co-organizer of the Early Career Workshop for junior faculty and senior Ph.D. students interested in academia.

- Krishna presented an invited talk entitled, “Formalizing Design-space Exploration for Flexible AI Accelerators” during the Silicon Integration Initiative Low-Power Forum.”

- Lim presented at the engineering track Machine Learning and EDA: The Productivity Cycle and organized the research panel “Heterogeneous 3D or Monolithic 3D, Which Direction to Go?”

Technical Sessions

- Ananda Samajdar (recent Ph.D. graduate supervised by Krishna and now at IBM) presented his work “Self-Adaptive Reconfigurable Arrays (SARA): Learning Flexible GEMM Accelerator Configuration and Mapping-space using ML.”

- Ph.D. candidate Brian Crafton (supervised by Raychowdhury) presented his work “Improving Compute In-Memory ECC Reliability with Successive Correction”.

- Hao presented her work “H2H: Heterogeneous Model to Heterogeneous System Mapping with Computation and Communication Awareness”.

Learn more about the Design Automation Conference

L-R: Zishen Wan (Ph.D. candidate), Callie Hao (assistant professor), Rishov Sarkar (Ph.D. candidate), Poulami Das (Ph.D. candidate), and Anurag Kar (Ph.D. candidate) all won awards at DAC.

Ph.D. candidate Rishov Sarkar (right) won third place in “University Demo Best Demonstration.” He is supervised by ECE assistant professor Callie Hao (left).

ECE assistant professor Callie Hao presenting the popular tutorial “A Journey to SW/HW Co-design in Machine Learning: Fundamental, Advancement, and Application.”

Professor Sung Kyu Lim (right) and his former student Bon Woong Ku (middle) receiving the 2022 Donald O. Pederson Best Paper Award for their paper “Compact-2D: A Physical Design Methodology to Build Two-Tier Gate-Level 3D ICs” published in IEEE TCAD.”

Ph.D. candidate Poulami Das won the “Best Research Award” during the Ph.D. Forum at DAC.

Dan Watson

dwatson@ece.gatech.edu

IEN Networking Lunch

Calling all researchers!

All Georgia Tech faculty and researchers are invited to join leaders from the Institute for Electronics and Nanotechnology (IEN) and their colleagues from across campus for an informal, no-host networking lunch. This is a great opportunity to learn more about IEN, its research areas, and potential partnership opportunities.

IEN Networking Lunch

Calling all researchers!

All Georgia Tech faculty and researchers are invited to join leaders from the Institute for Electronics and Nanotechnology (IEN) and their colleagues from across campus for informal, no-host networking lunches. These are a great opportunity to learn more about IEN, its research areas, and potential partnership opportunities.

IEN Networking Lunch

Calling all researchers!

All Georgia Tech faculty and researchers are invited to join leaders from the Institute for Electronics and Nanotechnology (IEN) and their colleagues from across campus for informal, no-host networking lunches. These are a great opportunity to learn more about IEN, its research areas, and potential partnership opportunities.

Large-area Flexible Organic Photodiodes Can Compete With Silicon Devices

Spontaneous Formation of Nanoscale Hollow Structures Could Boost Battery Storage

Baking and Boiling Botnets Could Drive Energy Market Swings and Damage

Nanoscale "worms" provide new route to nano-necklace structures

NNCI Webinar: Education and Computation

Virtual Immersive Worlds for Experiential Learning of Quantum and Semiconductor Physics

Featuring Professor Azad Naeemi | School of Electrical and Computer Engineering at Georgia Tech.