Georgia Tech is taking a multi-disciplinary approach to the research and development of many of the “colors” of hydrogen production. Our range of investigations, technologies, and demonstrations involve various feedstocks, such as water and natural gas, and methods of production, like electrolysis.

Green

Hydrogen produced by electrolysis of water, using electricity from renewable sources like wind or solar. Zero CO2 emissions are produced.

Blue

Hydrogen produced from fossil fuels (i.e., grey, black, or brown hydrogen) where Co2 is captured and either stored or repurposed.

Grey

Hydrogen extracted from natural gas using steam-methane reforming. This is the most common form of hydrogen production in the world today.

Purple/Pink/Red

Hydrogen produced with nuclear energy.

Purple: Chemo-thermal hybrid electrolysis

Pink: Electrolysis

Red: High-temp catalytic H20 splitting

Turquoise

Hydrogen produced by thermal splitting of methane (methane pyrolysis). Instead of CO2, solid carbon is produced.

Black/Brown

Hydrogen extracted from coal using gasification.

Yellow

Hydrogen produced by electrolysis using grid electricity from various sources (i.e., renewable and fossil fuels).

White

Hydrogen produced as a byproduct of industrial processes. Also refers to hydrogen occurring in its (rare) natural form.

Research Highlight

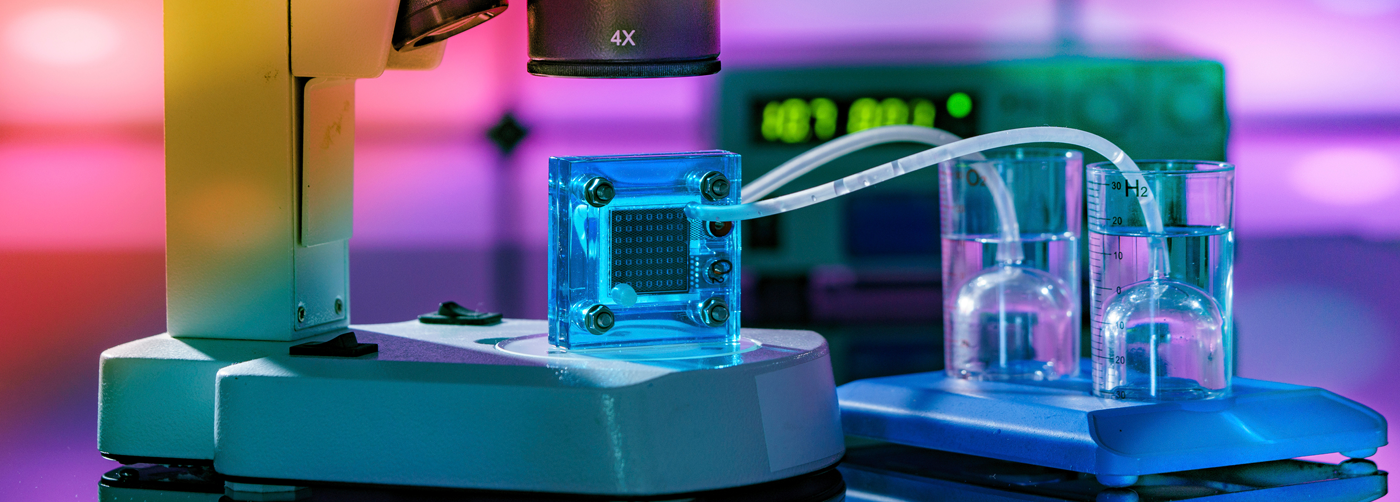

Advancing “Green” H2 through High-Efficiency Reversible Solid Oxide Cells (rSOCs)

Reversible solid oxide cells (rSOCs) are one of the cleanest and most efficient options for energy storage and conversion via high-efficiency electrolysis of water to hydrogen and oxygen. They are considered an enabler for the implementation of intermittent renewable energy technologies. For example, they are ideally suited for load leveling to bridge the gap between the production and the use of electricity. The commercialization of these systems, however, hinges on rational design of novel materials with exceptional functionalities across an expanded domain of temperatures. This will dramatically reduce the cost while enhancing performance and durability. Under the support of the US Department of Energy (DE-EE0008439, DE-FE0031975, and DE-FE0032115) and Phillips 66, Georgia Tech (via the leadership of Regents Professor and Hightower Chair Meilin Liu, School of Materials Science and Engineering) is conducting frontier research and development of advanced rSOC technology based on proton conductors, which has potential to dramatically reduce the cost while enhancing the performance and durability of the system. Current research focuses upon the development of novel proton-conducting electrolytes, mixed-conducting electrodes, and highly-active and durable catalysts for a new generation of rSOCs. They have the potential to be transformative and disruptive in advancing hydrogen production technology. Further, the scientific knowledge acquired can also advance other membrane reactor technologies for electrolysis of CO2 or production of ammonia and other hydrocarbon fuels.

Figure 1. (a) Schematic illustration of a proton-conducting electrolyte-based reversible solid oxide cell, (b) achieved peak power densities in the fuel cell mode (left) and current densities at 1.3 V in the electrolysis mode at 600 °C, (c) duration of stability test and degradation rate (mV h−1) comparison.

Researchers Active in Hydrogen Production

Faisal Alamgir - MSE

Ron Chance - ChBE

Yongsheng Chen - CEE

David Citrin - ECE

Andrei Fedorov - ME

Marta Hatzell - ME

Comas Haynes - GTRI

Seung Soon Jang - MSE

Paul Kohl - ChBE

Bill Koros - ChBE

Dan Kotlyar - ME/NRE

Seung Woo Lee - ME

Meilin Liu - MSE

Nian Liu - ChBE

Ryan Lively - ChBE

Matt McDowell - ME/MSE

Andrew Medford - ChBE

Sankar Nair - ChBE

Jinho Park - GTRI

Bojan Petrovic - ME-NRE

Carsten Sievers - ChBE

Vigor Yang - AE