Saad Bhamla Named 2025 Schmidt Polymath

Sep 16, 2025 —

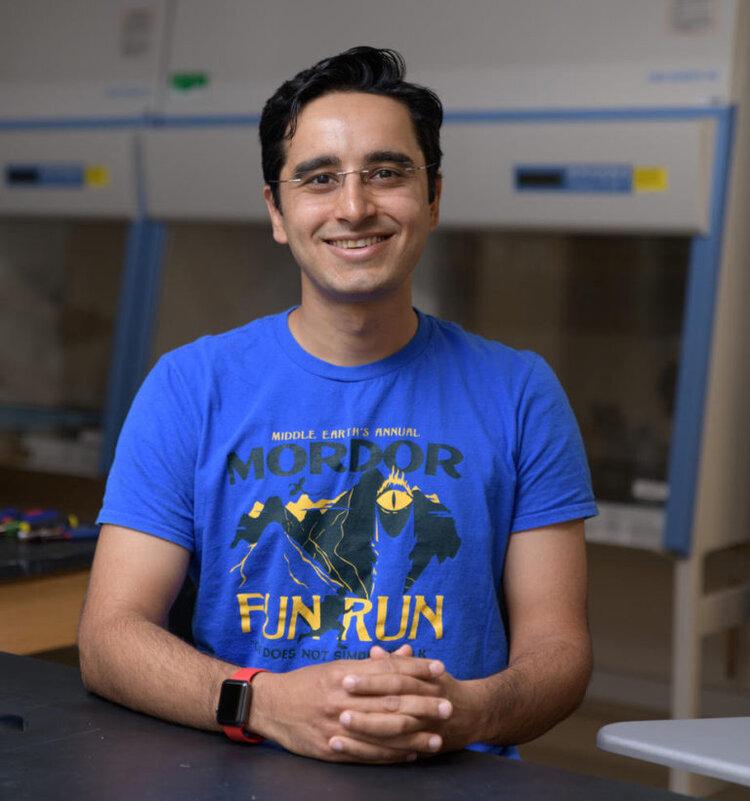

Saad Bhamla, associate professor in Georgia Tech's School of Chemical and Biomolecular Engineering

Saad Bhamla of Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE) is a member of a global cohort of eight scientists and engineers who were named Schmidt Polymaths. They will each receive up to $2.5 million over five years to pursue research in new disciplines or using new methodologies, Schmidt Sciences announced today.

As Schmidt Polymaths, the researchers pursue new approaches compared to previous work. The new cohort of polymaths will answer questions like how to expand access to healthcare with low-cost technologies, what happens to our chromosomes when we age and how to create more accurate computer simulations of climate.

Bhamla, associate professor in ChBE@GT, will develop low-cost technologies to tackle planetary-scale challenges, including AI-enabled point-of-care diagnostics in low-resource environments. He will also engineer autonomous morphing machines that adapt, evolve and learn like living systems.

The eight selected scientists represent the fifth cohort of the highly selective Schmidt Polymaths program. Awardees must have been tenured—or achieved similar status—within the previous three years. Previous cohorts have used the award to design new sensor devices, perform experiments at atomic resolutions, analyze trees of life with faster and more efficient algorithms, discover new mathematical formulas assisted by AI, and more.

Drawn from universities worldwide and selected through a competitive application process, Schmidt Polymaths are required to demonstrate past ability and future potential to pursue early-stage, novel research that would otherwise be challenging to fund—even without the current dramatic declines in U.S. funding for science.

“Our world is one deeply interconnected system---but to study it more deeply, we’ve divided it into increasingly narrow categories,” said Wendy Schmidt, who co-founded Schmidt Sciences with her husband Eric. “Schmidt Polymaths see the bigger picture, pursue answers beyond boundaries and expand the edges of what’s possible. Their work can help steer us all toward a healthier future, for people and the planet.”

About Schmidt Sciences

Schmidt Sciences is a nonprofit organization founded in 2024 by Eric and Wendy Schmidt that works to accelerate scientific knowledge and breakthroughs with the most promising, advanced tools to support a thriving planet. The organization prioritizes research in areas poised for impact including AI and advanced computing, astrophysics, biosciences, climate, and space—as well as supporting researchers in a variety of disciplines through its science systems program.

RELATED: Forbes featured Bhamla in the article: Saad Bhamla Is A Polymath

Brad Dixon, braddixon@gatech.edu

Lauren Steimle Named as New Pillar 1 Co-Lead in Children’s Healthcare of Atlanta Pediatric Technology Center (PTC)

Sep 16, 2025 —

We’re pleased to share that Lauren Steimle, the Harold R. and Mary Anne Nash Early Career Professor and Assistant Professor in the H. Milton Stewart School of Industrial and Systems Engineering (ISyE), has been named co-lead of the Data Science, Machine Learning, and Artificial Intelligence (Pillar 1) initiative within the Children’s Healthcare of Atlanta Pediatric Technology Center (PTC) at Georgia Tech.

Steimle’s work applies operations research and machine learning to improve medical decision-making and advance population health, with a focus on maternal and child health. Her recent projects explore maternal healthcare access, prevention of severe maternal morbidity from cardiovascular conditions, and strategies to prevent and control poliovirus outbreaks.

Read the full story here.

A Nexus of Ideas

Sep 11, 2025 —

Graphic Representation of networked system: Adobe Stock

The recently awarded $20mil NSF Nexus Supercomputer grant to Georgia Tech and partner institutes promises to bring incredible computing power to the CODA building. But what makes this supercomputer different and how will it impact research in labs on campus, across disciplinary units, and across institutions?

Purpose Built for AI Discovery

Nexus is Georgia Tech’s next-generation supercomputer, replacing the HIVE. Most operational high-performance computing systems utilized for research were designed before the explosion in Machine Learning and AI. This revolution has already shown successes for scientific research and data analysis in many domains, but the compute power, complex connectivity, and data storage needs for these systems have limited their access to the academic research community. The Nexus supercomputer design process retained a robust HPC system as a base while integrating artificial intelligence, machine learning and large-scale data science analysis from the ground up.

Expert Support for Faculty and Researchers

The Institute for Data Engineering and Science (IDEaS) and the College of Computing house the Center for Artificial Intelligence in Science and Engineering (ARTISAN) group. This team has collective experience in working with national computational, cloud, commercial and institutional resources for computational activities, and decades of experience in scientific tools that aid in assisting both teaching and research faculty. Nexus is the next logical step, bringing together everything they’ve learned to build a national resource optimized for the future of AI-driven science.

Principal Research Scientist for the ARTISAN Team, Suresh Marru, highlighted the need for this new resource, “AI is a core part of the Nexus vision. Today, researchers often spend more time setting up experiments, managing data, or figuring out how to run jobs on remote clusters than doing science. With Nexus, we’re flipping that script. By embedding AI into the platform, we help automate routine tasks, suggest optimal ways to run simulations, and even assist in generating input or analyzing results. This means researchers can move faster from question to insight. Instead of wrestling with infrastructure, they can focus on discovery.”

An Accessible AI Resource for GT & US Scientific Research

90% of Nexus capacity will be made available to the national research community through the NSF Advanced Computing Systems & Services (ACSS) program. Researchers from across the country, at universities, labs, and institutions of all sizes, will have access to this next-generation AI-ready supercomputer. For Georgia Tech research faculty and staff, the new system has multiple benefits:

- 10% of the time on the machine will be available for use by Georgia Tech researchers

- Nexus will allow GT researchers a chance to try out the latest hardware for AI computing

- Thanks to cyberinfrastructure tools from the ARTISAN group, Nexus will be easier to access than previous NSF supercomputers

David Sherrill, Interim Executive Director of IDEaS notes, "Nexus brings Georgia Tech's leadership in research computing to a whole new level. It will be the first NSF Category I Supercomputer hosted on Georgia Tech's campus. The Nexus hardware and software will boost research in the foundations of AI, and applications of AI in science and engineering."

Psychological Fallout: DARPA-Backed Project Addresses Societal Toll of Cyberattacks

Sep 10, 2025 —

The United States has prepared for decades to defend itself from every conceivable military conflict on its shores, but it turns out psychological warfare, not missiles, might pose the greatest threat to national security.

This is a challenge Assistant Professor Ryan Shandler will spend the next two years exploring as a recipient of the Young Faculty Award from the Defense Advanced Research Projects Agency (DARPA).

DARPA uses this award to recognize up-and-coming early-career faculty it hopes to continue working with in the future.

Currently, DARPA is concerned with cyberattacks from foreign countries aimed at provoking social unrest and eroding public trust in democratic institutions. In a study released last year by Microsoft, it was estimated that 600 million cyberattacks were launched everyday by criminals and nation-state actors from July 2023 to July 2024.

Tools built by cybersecurity engineers help mitigate the attacks made by criminals and in some cases even help track down stolen money. However, nation-state actors don’t launch cyberattacks to score a payday.

Instead, they attack things like power plants or voting precincts as a show of strength. Exposing these vulnerabilities shows how unsafe life could be, and these actors want nothing more than to cause total panic.

So now instead looking only to hardware and software for the solution to this problem, DARPA is investing in the human dimension of cybersecurity.

This area has long been a focus of Shandler’s research, making him uniquely qualified to confront this previously overlooked vulnerability. His past experiments have already shown how cyberattacks generate severe public anxiety and prompt calls for physical military retaliation.

For this new project, he will track a controlled population of several thousand people by exposing them to simulated cyberattacks. At no point will the participants be made to think the attacks are real. Shandler and his team will then interview the participants to gauge how their experience impacted their perception of security.

“We are looking to see which groups are more susceptible to this kind of cumulative threat. Once we model the risk, the next step will be building countermeasures to defend against it,” he said.

However, creating a defense system that promotes societal resilience will be as challenging as it is revolutionary.

"I'm fortunate to be conducting this research in an interdisciplinary unit like the School of Cybersecurity and Privacy. Tackling a challenge of this scale requires computer scientists and social scientists working side by side,” Shandler said.

“Alone, neither field stands a chance—but together, we stand a real chance of success."

Shandler is jointly appointed with the School of Cybersecurity and Privacy and the Sam Nunn School of International Affairs.

John Popham Communications Officer II | School of Cybersecurity and Privacy

Georgia Tech Team Designing Robot Guide Dog to Assist the Visually Impaired

Sep 10, 2025 —

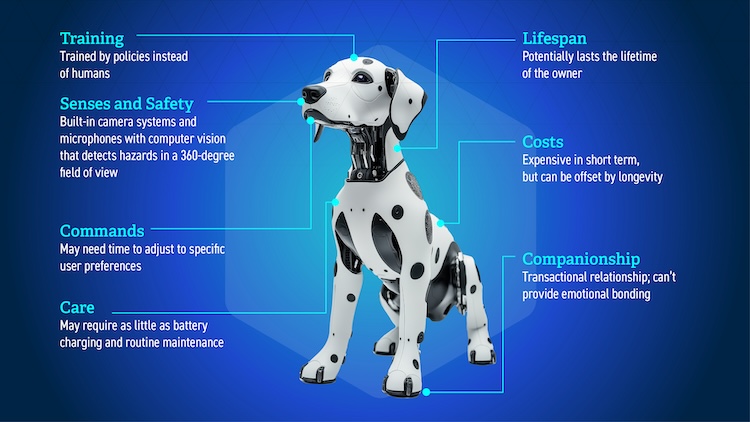

People who are visually impaired and cannot afford or care for service animals might have a practical alternative in a robotic guide dog being developed at Georgia Tech.

Before launching its prototype, a research team within Georgia Tech’s School of Interactive Computing, led by Professor Bruce Walker and Assistant Professor Sehoon Ha, is working to improve its methods and designs based on research within blind and visually impaired (BVI) communities.

“There’s been research on the technical aspects and functionality of robotic guide dogs, but not a lot of emphasis on the aesthetics or form factors,” said Avery Gong, a recent master’s graduate who worked in Walker’s lab. “We wanted to fill this gap.”

With training a guide dog costing up to $50,000, few BVI individuals can afford one, and even fewer can afford to care for and feed it. The dog also has fewer than 10 working years before it needs replacement.

Gong co-authored a paper on the design implications of the robotic guide dog that was presented at the 2025 International Conference on Robotics and Automation (ICRA) in Atlanta in May.

The consensus among the study’s participants indicates they prefer a robotic guide dog that:

- resembles a real dog and appears approachable

- has a clear identifier of being a guide dog, such as a vest

- has built-in GPS and Bluetooth connectivity

- has control options such as voice command

- has soft textures without feeling furry

- has long battery life and self-charging capability

“A lot of people said they didn’t want the dog to look too cute or appealing because it would draw too much attention,” said Aviv Cohav, another lead author of the paper and recent master’s graduate.

“Many people have issues with taking their guide dog to places, whether it’s little kids wanting to play with the dog or people not liking dogs or people being scared of them, and that reflects on the owners themselves. We wanted to look at what would be a good balance between having a functional robot that wouldn’t scare people away or be a distraction.”

The researchers also had to consider the perspectives of sighted individuals and how society at large might view a robotic guide dog.

An example of this is the amount of noise the dog makes while walking. The owner needs to hear the dog is active, but the clanky sound many off-the-shelf robots make could create disturbances in indoor spaces that amplify sounds. To offset the noise, the team developed algorithms that allow the robot to move more quietly.

Walker and his lab have examined similar scenarios that must take public perception into account.

“We like to think of Georgia Tech as going the extra mile,” Walker said. “Let’s not just make a robot, but a robot that’s going to fit into society.

“To have impact, the technologies we produce must be produced with society in mind. This is a holistic design that considers the users and all the people with whom the users interact.”

Taery Kim, a computer science Ph.D. student, began working on the concept of a robotic guide dog when she came to Georgia Tech in 2022. She and Ha, her advisor, have authored papers on building the robot’s navigation and safety components.

“When I started, I thought it would be as simple as giving the guide dog a command to take me to Starbucks or the grocery store, and it would just take me,” Kim said. “But the user must give waypoint directions — ‘go left here,’ ‘turn right,’ ‘go forward,’ ‘stop.’ Detailed commands must be delivered to the dog.”

While a real dog has naturally enhanced senses of hearing and smell that can’t be replicated, technology can provide interconnected safety features during an emergency. The researchers envision a camera system equipped with a 360-degree field of view, computer vision algorithms that detect obstacles or hazards, and voice recognition that recognizes calls for help. An SOS function could automatically call 911 at the owner’s request or if the owner is unresponsive.

Kim said the robot should also have explainability features to enhance communication with the owner. For example, if the robot suddenly stops or ignores an owner’s commands, it should tell the owner that it’s detecting a hazard in their path.

Manufacturing a robot at scale would initially be expensive, but the researchers believe the cost would eventually be offset because of its longevity. BVI individuals may only need to purchase one during their lifetime.

To introduce a prototype, the multidisciplinary research team recognizes that it needs to enlist experts from other fields to adequately address the various implications and research gaps inherent in the project.

Walker said the teams welcome additional partners who are keen to tackle challenges ranging from design and engineering to battery life to human-robot interaction.

Nathan Deen, Communications Officer

School of Interactive Computing

nathan.deen@cc.gatech.edu

Georgia Tech Researchers Named Finalists for Prestigious Blavatnik Science Awards

Sep 09, 2025 — Atlanta, GA

Headshots of Matthew McDowell and Ryan Lively

Two Georgia Tech researchers in the College of Engineering have been named finalists for the 2025 Blavatnik National Awards for Young Scientists. Their discoveries, which could create cleaner industrial processes and safer, more reliable batteries, have important potential impacts for daily life.

The Blavatnik Awards are presented by the Blavatnik Family Foundation and are administered by the New York Academy of Sciences. They honor the most promising early-career researchers in the U.S., across life sciences, chemistry, and physical sciences, and engineering. The awards are among the most prestigious and competitive in science.

This dual recognition underscores Georgia Tech’s growing national leadership in high-impact, interdisciplinary research.

Ryan Lively, Thomas C. DeLoach Jr. Endowed Professor in the School of Chemical and Biomolecular Engineering, is recognized in the Chemical Sciences category for pioneering scalable technologies that will reduce industrial carbon emissions and energy use. He develops new materials that can capture carbon and separate chemicals, using much less energy than conventional methods. His innovations could make industry cleaner and play a key role in addressing climate change.

Matthew McDowell, Carter N. Paden Jr. Distinguished Chair in the George W. Woodruff School of Mechanical Engineering holds a joint appointment in the School of Materials Science and Engineering. Recognized in the Physical Sciences and Engineering category for groundbreaking battery research, he and his team develop new materials to make batteries last longer and store more energy. He has discovered ways to visualize how battery materials change during use — insights that help improve the performance and safety of future energy technologies.

This year’s 18 finalists were selected from 310 nominees. On Oct. 7, 2025, three laureates will be announced at a gala at New York City’s American Museum of Natural History. Each laureate will receive $250,000, the largest unrestricted scientific prize for early-career researchers in the U.S.

Shelley Wunder-Smith

AI’s Ballooning Energy Consumption Puts Spotlight On Data Center Efficiency

Sep 03, 2025 —

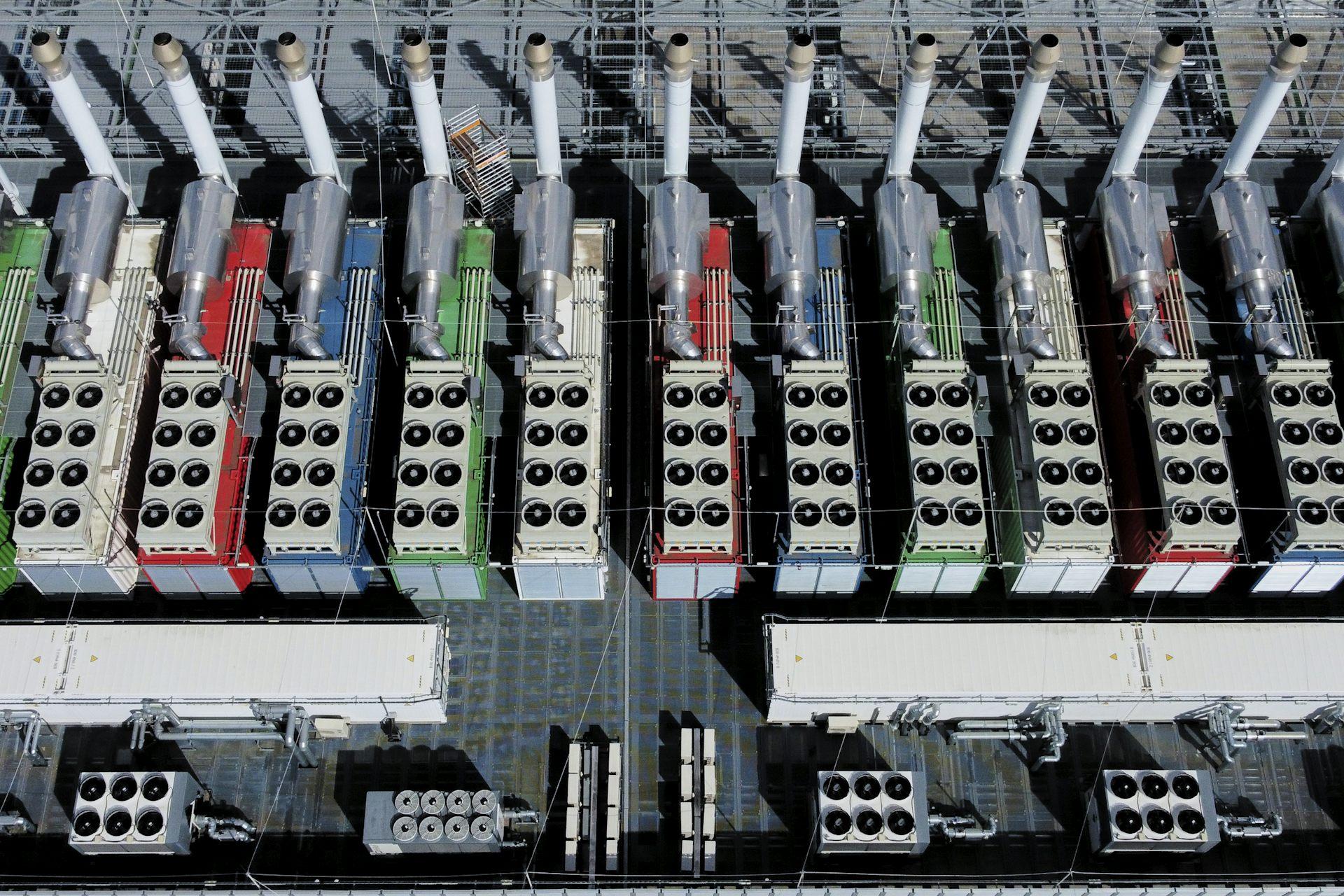

These ‘chillers’ on the roof of a data center in Germany, seen from above, work to cool the equipment inside the building. AP Photo/Michael Probst

Artificial intelligence is growing fast, and so are the number of computers that power it. Behind the scenes, this rapid growth is putting a huge strain on the data centers that run AI models. These facilities are using more energy than ever.

AI models are getting larger and more complex. Today’s most advanced systems have billions of parameters, the numerical values derived from training data, and run across thousands of computer chips. To keep up, companies have responded by adding more hardware, more chips, more memory and more powerful networks. This brute force approach has helped AI make big leaps, but it’s also created a new challenge: Data centers are becoming energy-hungry giants.

Some tech companies are responding by looking to power data centers on their own with fossil fuel and nuclear power plants. AI energy demand has also spurred efforts to make more efficient computer chips.

I’m a computer engineer and a professor at Georgia Tech who specializes in high-performance computing. I see another path to curbing AI’s energy appetite: Make data centers more resource aware and efficient.

Energy and Heat

Modern AI data centers can use as much electricity as a small city. And it’s not just the computing that eats up power. Memory and cooling systems are major contributors, too. As AI models grow, they need more storage and faster access to data, which generates more heat. Also, as the chips become more powerful, removing heat becomes a central challenge.

Data centers house thousands of interconnected computers. Alberto Ortega/Europa Press via Getty Images

Cooling isn’t just a technical detail; it’s a major part of the energy bill. Traditional cooling is done with specialized air conditioning systems that remove heat from server racks. New methods like liquid cooling are helping, but they also require careful planning and water management. Without smarter solutions, the energy requirements and costs of AI could become unsustainable.

Even with all this advanced equipment, many data centers aren’t running efficiently. That’s because different parts of the system don’t always talk to each other. For example, scheduling software might not know that a chip is overheating or that a network connection is clogged. As a result, some servers sit idle while others struggle to keep up. This lack of coordination can lead to wasted energy and underused resources.

A Smarter Way Forward

Addressing this challenge requires rethinking how to design and manage the systems that support AI. That means moving away from brute-force scaling and toward smarter, more specialized infrastructure.

Here are three key ideas:

Address variability in hardware. Not all chips are the same. Even within the same generation, chips vary in how fast they operate and how much heat they can tolerate, leading to heterogeneity in both performance and energy efficiency. Computer systems in data centers should recognize differences among chips in performance, heat tolerance and energy use, and adjust accordingly.

Adapt to changing conditions. AI workloads vary over time. For instance, thermal hotspots on chips can trigger the chips to slow down, fluctuating grid supply can cap the peak power that centers can draw, and bursts of data between chips can create congestion in the network that connects them. Systems should be designed to respond in real time to things like temperature, power availability and data traffic.

Break down silos. Engineers who design chips, software and data centers should work together. When these teams collaborate, they can find new ways to save energy and improve performance. To that end, my colleagues, students and I at Georgia Tech’s AI Makerspace, a high-performance AI data center, are exploring these challenges hands-on. We’re working across disciplines, from hardware to software to energy systems, to build and test AI systems that are efficient, scalable and sustainable.

Scaling With Intelligence

AI has the potential to transform science, medicine, education and more, but risks hitting limits on performance, energy and cost. The future of AI depends not only on better models, but also on better infrastructure.

To keep AI growing in a way that benefits society, I believe it’s important to shift from scaling by force to scaling with intelligence.![]()

This article is republished from The Conversation under a Creative Commons license. Read the original article.

Author:

Divya Mahajan, assistant professor of Computer Engineering, Georgia Institute of Technology

Media Contact:

Shelley Wunder-Smith

shelley.wunder-smith@research.gatech.edu

How a Veteran Gained Invaluable Skills in AI Manufacturing at Georgia Tech

Aug 01, 2025 —

Air Force veteran Michael Trigger completed an internship at Georgia Tech's Advanced Manufacturing Pilot Facility.

Michael Trigger, an Air Force veteran in his late 50s, found an unexpected opportunity at Georgia Tech. After driving a truck for several years, he was ready to learn some new skills.

Trigger’s interest in artificial intelligence (AI) led him to a manufacturing course at the Veterans Education Career Transition Resource Center in Warner Robins, Georgia. With support from the Georgia Tech-led Georgia Artificial Intelligence in Manufacturing program (Georgia AIM), the center trains veterans in robotics using cutting-edge AI manufacturing technologies.

Digital Dashboard Helps Everyone Find Accessible Climate Solutions in Georgia

Sep 04, 2025 —

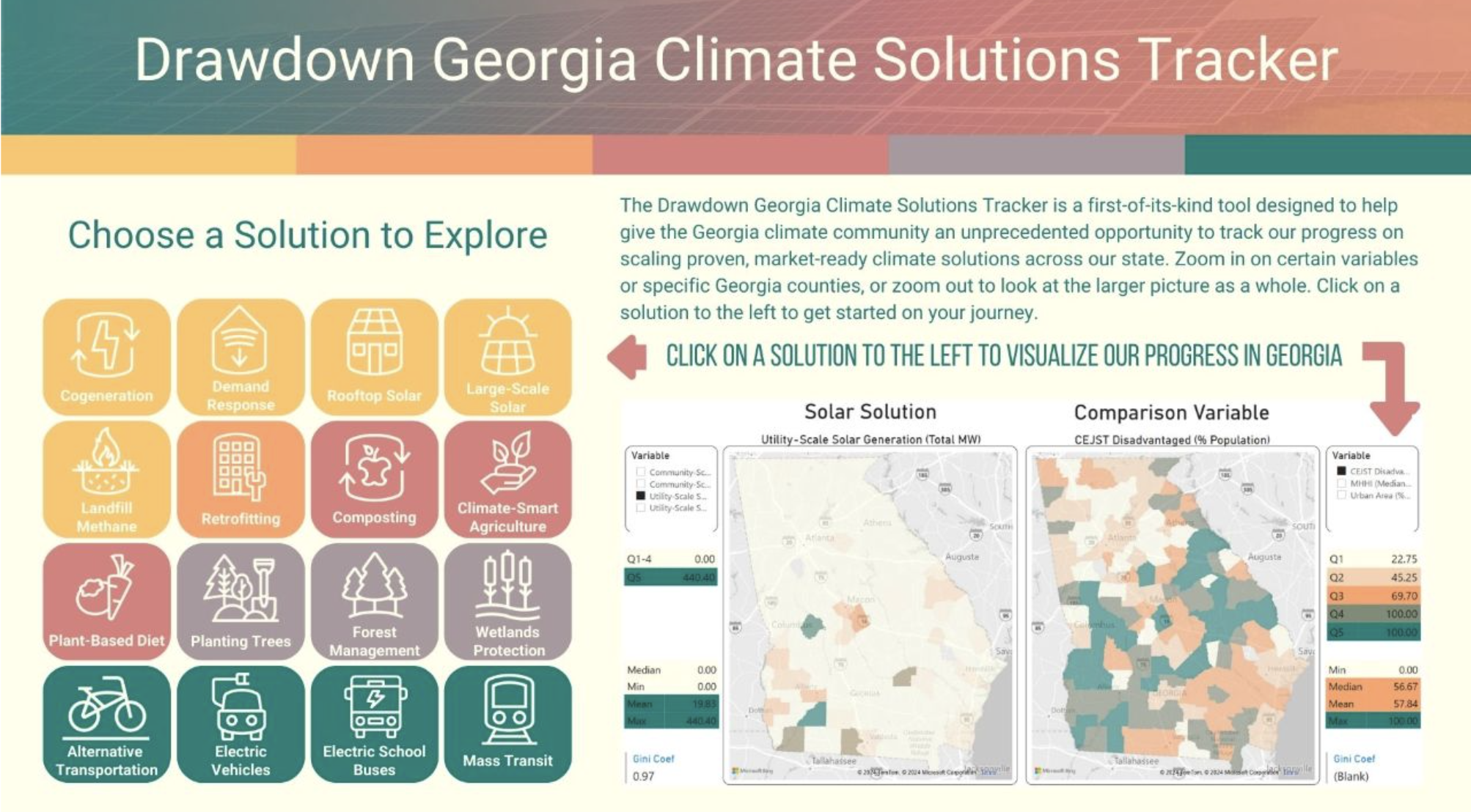

Electric vehicles. Rooftop solar. Cycling to work. Knowing where to start when reducing your personal carbon footprint can be daunting. But a new tool from Georgia Tech makes it easier for anyone to figure out how they can help address climate change.

The Drawdown Georgia Solutions Tracker is a digital dashboard that enables everyday Georgians to see how effective various technologies could be for each county. The tracker analyzes public data for 16 solutions — from planting trees to public transit — that can lower greenhouse gas emissions. The tracker is equally essential for policymakers and business leaders, enabling them to identify opportunities to propose legislation or adjust operations to reduce carbon emissions.

To use the tracker, viewers click on a solution to see its impact. Then, they specify a particular county, and the data is tailored to the most relevant metric. For example, if someone picks “plant-based diet” as a solution, they can see how many vegan restaurants are already in their county. The tracker also contrasts the climate solution with a relevant area that might benefit if the solution is implemented. For the plant-based example, the tracker compares it to urban density.

This tracker is one of the many initiatives of Drawdown Georgia, one of the Ray C. Anderson Foundation’s key funding initiatives based on research conducted by Georgia Tech, Georgia State University, the University of Georgia, and Emory University. Drawdown Georgia's goal is to reduce Georgia’s carbon impact by 57% by 2030 and to accelerate Georgia’s progress toward net-zero greenhouse emissions.

Drawdown Georgia also developed a carbon emissions tracker that shows carbon emission levels by county. The dashboard was a success, but the Drawdown Georgia team wanted to create a more proactive tool. The Solutions Tracker was designed so that anyone could make smalldaily changes to improve the climate — not just track it.

“We began the Drawdown Georgia project with the goal of cutting state pollution significantly,” said Marilyn Brown, Regents' Professor and the Brook Byers Professor of Sustainable Systems in the Jimmy and Rosalynn Carter School of Public Policy. "To get Georgians involved, we decided to focus on local and regional opportunities to reduce emissions.”

Drawdown Data

The data combines federal and state sources from the U.S. Energy Information Administration, the National Renewable Energy Laboratory, and the Department of Agriculture. Some solutions may seem obvious, like planting trees, but others are more niche. For example, decomposing trash often produces methane gas, which means that landfills contribute to greenhouse gas emissions — important information for policymakers to consider when developing carbon reduction strategies.

The researchers hope everyone will use the tracker. Politicians and policymakers can find new ideas for legislation or the adoption of these solutions. Business leaders can find opportunities to hit their decarbonization goals. Georgians can use the tracker to figure out which solutions are most sustainable for their lives. Even scientists can learn which methods to home in on for their research. Since the tracker is available via Creative Commons, anyone can use the data to build their own tools or models.

The tracker is already having a real-world impact. Brown and the Drawdown Georgia team have collaborated with the state of Georgia and the 29-county metro Atlanta area on their carbon action plans. They’ve also partnered with 75 businesses on carbon action plans and other solutions through the Drawdown Georgia Business Compact, managed by the Ray C. Anderson Center for Sustainable Business in the Scheller College of Business. As these stakeholders ask questions about different climate solution impacts, the team has expanded the tracker accordingly. They’ve also recently redesigned the user interface to make it even more accessible for everyday users.

From improved public health to business opportunities, the state requires reduced greenhouse gases, and Georgia Tech is not only tracking emissions but helping to fix the problem, too.

Tess Malone, Senior Research Writer/Editor

tess.malone@gatech.edu