New Interdisciplinary Research Institute to Launch This Summer

Nov 17, 2023 —

The Institute for Electronics and Nanotechnology (IEN) and the Institute for Materials (IMat) have announced they will combine to form a new Interdisciplinary Research Institute (IRI) set to begin operations on July 1, 2024.

The new IRI, which has yet to be named, will explore the vast scientific, technological, societal, and economic impacts of innovative materials and devices, as well as foster their incorporation into systems that improve the human condition in areas such as information and communication technologies, the built environment, and human well-being and performance.

“The new IRI will not only combine the strengths of IEN and IMat, but will also allow us to further expand faculty representation from across the Institute,” said Julia Kubanek, vice president of Interdisciplinary Research at Georgia Tech. “As we look at the future of research in these areas, expanding inclusivity of researchers from the liberal arts, design, business, and basic sciences will allow us to better meet the education, workforce development, and innovation needs of Georgia, the U.S., and the world.”

The new IRI will strengthen Georgia Tech’s role in national focus areas such as the National Nanotechnology Initiative, the Materials Genome Initiative, and the CHIPS and Science Act, as well as identify and shape future priorities.

Core competencies of the new IRI will include:

- Fundamental science to comprehend and control matter from the nanoscale to the mesoscale.

- The synthesis, processing, and characterization of materials to achieve desired properties.

- The design and fabrication of novel devices and components with enhanced capabilities.

- The integration of materials, devices, and components into larger systems.

- Computing, modeling, simulation, and big data to advance progress at all length scales.

- Integration into all stages of research, from conceptualization to impact assessment, of economic, business, and social factors to ensure sustainable and evenly distributed benefits.

“IEN and IMat have worked closely together for years, and there is overlap in the research areas we cover,” said Eric Vogel, IMat’s executive director. “This is an opportunity for us to build on IEN and IMat’s individual successes and our strong record of collaboration to create something even more exceptional.”

The new IRI will strengthen the state-of-the-art core cleanroom and characterization facilities, providing researchers with the tools and resources necessary for cutting-edge interdisciplinary research. These facilities will continue to serve both Georgia Tech and, through its leadership within the NSF National Nanotechnology Coordinated Infrastructure, the nation. Recognizing the importance of nurturing talent, it will champion education and outreach programs to inspire the next generation and equip the workforce with the skills necessary to collaborate and communicate across multiple disciplines.

“This is an exciting time to look to the future,” said Michael Filler, interim executive director of IEN. “We highly value the dedication and hard work of our staff and research faculty, who have been crucial to the success of IEN and IMat and will be the backbone of this new organization. We look forward to creating something exceptional in the coming months.”

Laurie Haigh

laurie.haigh@research.gatech.edu

Birdwatchers with Lauren Wilson from Wild Nest Bird Rehab & Zoo Atlanta

General Meeting for Birdwatchers @ GT! We will be hosting speaker Lauren Wilson.

Georgia Tech Leads Department of Energy’s Earthshots Funding with Seven Projects

Nov 09, 2023 — Atlanta, GA

Projects address basic research challenges facing the Energy Earthshots Initiative to mitigate climate change and reach a net-zero carbon economy.

Georgia Tech faculty and researchers are involved in five university-led projects and two new Energy Earthshot Research Centers that are part of a $264 million grant from the U.S. Department of Energy (DOE). The funding includes establishing 11 new Energy Earthshot Research Centers (EERC) led by DOE’s national labs and 18 university research teams addressing one or more of DOE’s Energy Earthshots initiatives focused on industrial decarbonization, carbon storage and removal, offshore wind, and more.

University Projects

University research teams will conduct crosscutting, fundamental research to address knowledge gaps that limit achievement of the Energy Earthshots goals. These teams are focused on scientific challenges spanning the Office of Science research portfolio and complement work done by the EERCs.

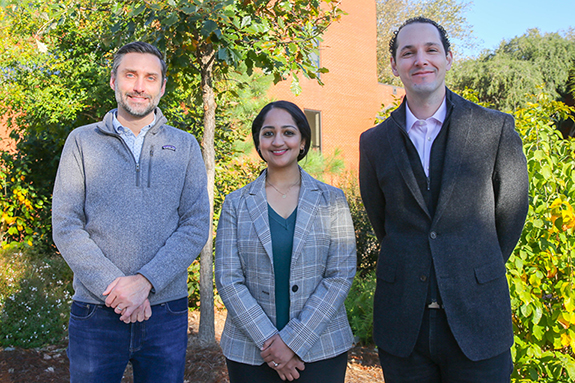

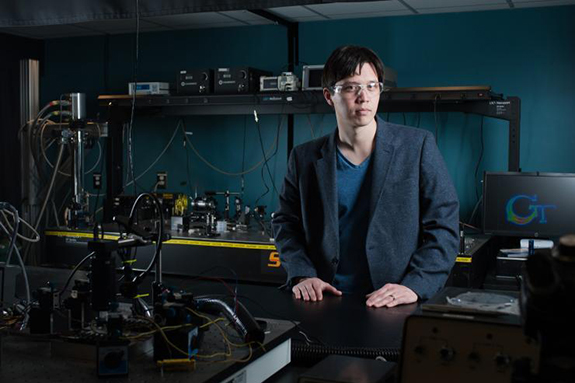

Matthew McDowell, Akanksha Menon, and Claudio Di Leo

Akanksha Menon, assistant professor in the George W. Woodruff School of Mechanical Engineering, has been awarded $3 million in funding to lead a university project titled “Understanding Thermo-Chemo-Mechanical Transformations in Thermal Energy Storage Materials and Composites.” The project will bring together Matthew McDowell, associate professor in the Woodruff School; Claudio Di Leo, assistant professor in the Daniel Guggenheim School of Aerospace Engineering; and Jeff Urban from the Lawrence Berkeley National Laboratory to provide a fundamental understanding of the coupled thermo-chemo-mechanical phenomena in thermal energy storage materials that will enable low-cost and stable storage.

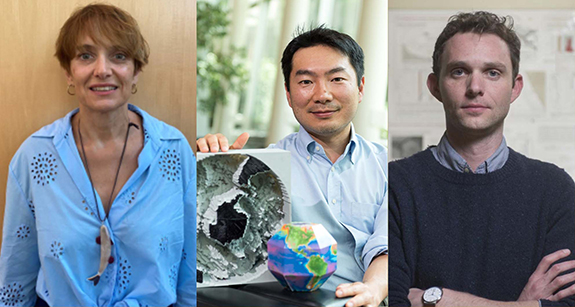

Annalisa Bracco, Taka Ito, and Chris Reinhard

Annalisa Bracco, professor and associate chair; Taka Ito, professor; and Chris Reinhard, Georgia Power Chair and associate professor — all from the School of Earth and Atmospheric Sciences — will join colleagues from Princeton, Texas A&M, and Yale University for an $8 million Earthshot project that will build an “end-to-end framework” for studying the impact of carbon dioxide (CO2) removal efforts. The project, titled “Carbon dioxide removal and high-performance computing: Planetary Boundaries of Earth Shots,” includes creating computer models to measure how well CO2 removal techniques work on land, rivers, and oceans.

Elizabeth Qian, assistant professor in the Guggenheim School and the School of Computational Science and Engineering, will join colleagues from New York University, Los Alamos National Lab, and National Renewable Energy Lab for an Earthshot project titled “Learning reduced models under extreme data conditions for design and rapid decision-making in complex systems (ROME).” The project will develop mathematical foundations and computational methods to support the design and operation of complex systems for carbon removal and renewable energy generation that will be used for simulation, design, and decision-making of the Floating Offshore Wind Shot and the Carbon Negative Shot EERCs.

David Flaherty, professor in the School of Chemical and Biomolecular Engineering will join colleagues from the University of Illinois Urbana-Champaign, Northern Arizona University, Texas State University, and Argonne National Lab to co-lead a project titled “Harnessing Electrostatics for the Conversion of Organics, Water and Air: Driving Redox on Particulate Liquids Earthshot (DROPLETS).” The overall objective of DROPLETS is to explore an approach based on microdroplet-enabled redox reactions (which involve the transfer of electrons between substances) toward H2 production (a clean and renewable energy source), CO2 activation (which can help mitigate greenhouse gas emissions), and the synthesis of redox species for long-duration energy storage.

Guoxiang (Emma) Hu, assistant professor in the School of Materials Science and Engineering, joins colleagues from Georgia State University, Carnegie Melon University, Oak Ridge National Lab, and the University of Utah on a project titled “Atomic Level Compositional Complexity for Electrocatalysis (Atomic-C2E).” Atomic-C2E will integrate fundamental electrochemistry, quantum chemical and multiscale simulations, and materials chemistry to develop an understanding of electrocatalysts that aid in the conversion of CO2 into value-added chemical fuels and hydrogen production via water electrolysis — and address technological bottlenecks challenging them.

National Lab Centers

The DOE national lab EERCs will bring together multi-institutional, multidisciplinary teams to perform energy-relevant research with a scope and complexity beyond what is possible in standard single-investigator or small-group awards. Addressing key research challenges relevant to the Energy Earthshots, the 11 new centers will be housed at eight DOE national laboratories and will receive a combined $195 million over four years.

Of the 11 lab centers, the DEGradation Reactions in Electrothermal Energy Storage (DEGREES) center led by the National Renewable Energy Laboratory consists of Professor Akanksha Menon and Associate Professor Shannon Yee from the Woodruff School. DEGREES is an EERC that will provide fundamental understanding of the science behind complex degradation mechanisms and instabilities that affect the performance of thermal energy storage.

Non-Equilibrium Energy Transfer for Efficient Reactions (NEETER) is the second EERC that will be housed at the Department of Energy's Oak Ridge National Laboratory (ORNL) and involves Georgia Tech. Led by David Sholl, director of ORNL’s transformational decarbonization initiative and professor in the School of Chemical and Biomolecular Engineering, NEETER is focused on developing chemical processes that use sustainable methods instead of burning fossil fuels to radically reduce industrial greenhouse gas emissions to stem climate change and limit the crisis of a rapidly warming planet.

About DOE’s Energy Earthshots Initiative

The Department of Energy launched the Energy Earthshots Initiative to spur decarbonization efforts that will help the United States meet climate and clean energy goals. The initiative connects DOE’s basic science and energy technology offices to accelerate innovations toward more abundant, affordable, and reliable clean energy solutions; seeks to revolutionize many sectors across the United States; and will rely on fundamental science and innovative technology to be successful.

Professor Elizabeth Qian will Serve as Co-PI on DoE Energy Earthshots Project

Qian will develop computing methods to support design and operation of complex systems for carbon removal and renewable energy generation.

Three Earth and Atmospheric Sciences Researchers Awarded DOE Earthshot Funding for Carbon Removal Strategies

Bracco, Ito, and Reinhard will create computer models to measure how well CO2 removal techniques work on land, rivers, and oceans, as part of $264 million in grants.

Assistant Professor Akanksha Menon Awarded $3 Million for Research as part of DOE's Energy Earthshots Initiative

Menon and her team will address two Energy Earthshots to help achieve net-zero carbon by 2050, combat climate crisis.

Professor David Sholl Leading New Energy Earthshot Research Center to Stem Climate Change

The Department of Energy also selected David Flaherty to co-lead a second project designed to lower energy input and reactor cost for complex chemical reactions.

Writer and Media Contact:

Priya Devarajan | priya.devarajan@research.gatech.edu

Eleven Appointed as BBISS Faculty Fellows

Oct 31, 2023 —

L to R: Omar Asensio; Christos Athanasiou; Fani Boukouvala; Peng Chen; Kelly Comfort; Constance Crozier; Ashutosh Dhekne; Jennifer Kaiser; Neha Kumar; Jian Luo; Akanksha Menon

Eleven new Faculty Fellows were appointed to the Brook Byers Institute for Sustainable Systems (BBISS). In addition to their own work, BBISS Fellows serve as a board of advisors to the BBISS; foster the culture and community of sustainability researchers, educators, and students at Georgia Tech; and communicate broadly the vision, mission, values, and objectives of the BBISS. Fellows will work with the BBISS for three years, with the potential for a renewed term.

The BBISS Faculty Fellows program has been in place since 2014. Fellows are drawn from across all 6 colleges and GTRI at Georgia Tech. BBISS Interim Executive Director Beril Toktay says, "I’m delighted with the diversity of backgrounds and disciplines among the fellows and look forward to seeing the strengthening ties and growing collaborations in the sustainability community."

The new BBISS Faculty Fellows are:

- Omar Asensio - Associate Professor, School of Public Policy

- Christos Athanasiou - Assistant Professor, Daniel Guggenheim School of Aerospace Engineering

- Fani Boukouvala - Associate Professor, School of Chemical and Biomolecular Engineering

- Peng Chen - Assistant Professor, School of Computational Science and Engineering

- Kelly Comfort - Professor, School of Modern Languages

- Constance Crozier - Assistant Professor, H. Milton Stewart School of Industrial and Systems Engineering

- Ashutosh Dhekne - Assistant Professor, School of Computer Science

- Jennifer Kaiser - Assistant Professor, Civil and Environmental Engineering and Earth and Atmospheric Sciences

- Neha Kumar - Associate Professor, Sam Nunn School of International Affairs and the School of Interactive Computing

- Jian Luo – Professor, School of Civil and Environmental Engineering

- Akanksha Menon - Assistant Professor, George W. Woodruff School of Mechanical Engineering

These faculty members will join the current roster of Faculty Fellows:

- Baabak Ashuri - Associate Professor, School of Building Construction

- Joe Bozeman – Assistant Professor, School of Civil and Environmental Engineering

- Dylan Brewer - Assistant Professor, School of Economics

- Kate Pride Brown- Associate Professor, School of History and Sociology

- Andre Calmon – Assistant Professor, Scheller College of Business

- Kevin Caravati – Principal Research Scientist, Georgia Tech Research Institute

- Ellen Dunham-Jones – Professor, School of Architecture

- Brian Gunter - Associate Professor, Daniel Guggenheim School of Aerospace Engineering

- Daniel Matisoff - Associate Professor, School of Public Policy

- Jenny McGuire – Assistant Professor, School of Earth and Atmospheric Sciences

- Jessica Roberts – Assistant Professor, College of Computing

- Ilan Stern – Senior Research Scientist, Georgia Tech Research Institute

- Yuanzhi Tang - Associate Professor, School of Earth and Atmospheric Sciences

- Anjali Thomas> - Associate Professor, Sam Nunn School of International Affairs

- Zhaohui Tong - Associate Professor, School of Chemical & Biomolecular Engineering

- Perry Yang – Professor, School of City and Regional Planning

More information can be found on the BBISS website.

Brent Verrill, Research Communications Program Manager, BBISS

Janelle Dunlap Turns Beekeeping Into Art

Oct 30, 2023 —

The Urban Honey Bee Project’s new beekeeper in residence is creating art and educating the public with her practice.

Hundreds of thousands of honeybees make their home atop The Kendeda Building for Innovative Sustainable Design, and it's up to Janelle Dunlap to make sure the hives thrive.

Dunlap was hired earlier this year as the Urban Honey Bee Project's (UHBP) first-ever beekeeper in residence. Throughout her residency, she'll conduct research into the pollinator's place in our ecosystem and how beekeeping may offer relief to veterans dealing with post-traumatic stress disorder (PTSD), while connecting with the bees through art.

Dunlap had been gardening for over a decade, but in 2016, when she got the urge to find new ways to engage with nature, she recalled a powerful piece of imagery that shaped her childhood — Wu-Tang Clan's music video for “Triumph” and its depiction of the group's members as a powerful swarm of Africanized killer bees.

"The political messaging and tying Africanized killer bees in with the stereotypes and the tropes of African Americans in the media, and the way that that was so poetically tied in, visually stuck with me,” she said. “It was the first time I recognized a political message being articulated through art. For that reason, it stuck with me that bees were a form of strong symbolism tied to resilience."

Living in Charlotte, North Carolina, Dunlap became a certified beekeeper under the Mecklenburg County Beekeepers Association in 2017. She continued practicing as she moved around the country, with stops in Chicago and Denver, eventually landing in Atlanta in 2021. Looking for a way to connect to the local beekeeping community, she attended an April presentation by UHBP Director Jennifer Leavey, who offered Dunlap a chance to get involved at Georgia Tech.

She now handles the inspection of the hives on The Kendeda Building roof, where she monitors for pests and ensures the bees have proper nutrition to sustain their population through the seasons. The UHBP began in 2012 with the goal of educating the Tech community on the importance of these pollinators within the Atlanta ecosystem and beyond — a charge that Dunlap carries on.

Over the next year, she will continue working on her sound art project that examines the frequency at which bees “buzz” and how it, along with the responsibilities of beekeeping, is being used by VA hospitals and programs to ease the effects of PTSD. While the science behind the connection is still being explored, beekeeping was recommended more than a century ago — to soldiers returning home from World War I — according to a CNBC profile of Bees4Vets, a nonprofit based in Nevada.

From the Hive to the Canvas

Whether it was baking sourdough bread or learning a new language, many people, including Dunlap, took the early days of the Covid-19 pandemic to pick up a new hobby. She began a master's program at the School of the Art Institute of Chicago with the goal of using beeswax in encaustic painting, which uses hot wax mixed with pigments. The use of natural materials collected through her beekeeping practice connects Dunlap to her work.

“It's a way of tapping into another level of consciousness. It's a way of articulating the noncommunicable relationship between me and the bees. When there's a language gap between people, we try to fill it in with translation, but without a direct way to translate the language or the sensation that I feel from the bees, this allows me to document my practice in an abstract form,” she said.

By layering the wax and applying heat throughout the process, Dunlap watches the pieces take shape, often with the unpredictability of an active hive, as she says the art “can create itself.” She collects the wax in small amounts, knowing that she can only produce her art if the bees are healthy.

"It's an eco-conscious practice, making sure I don't use more than I need," she explained. “I love the landscape it creates, and it's all about me creating a direct relationship with my medium and knowing that I earned it by developing a relationship with the bees."

As Dunlap continues her year-long residency with the UHBP, she intends to help educate the community, both on campus and around the Atlanta area, in the hopes that more prospective beekeepers will explore their curiosity to unlock the full potential of the practice.

"It's been a practice that keeps unveiling itself to me," she said. "As you get more engaged, you learn there is so much more to it than just the day-to-day hive inspections. There is a lot of beauty to it as well."

Students at Tech have several ways to get involved with research and beekeeping, including the Living Building Science VIP team, the Beekeeping Club, and various classes and workshops hosted by the UHBP.

Janelle Dunlap conducts a hive inspection at The Kendeda Building for Innovative Sustainable Design. Photo by Allison Carter.

Steven Gagliano - Institute Communications

BBISS Seminar Series - Jean de Dieu Hakizimana

African Center of Excellence in Energy for Sustainable Development, and the Grid Innovation and Incubation Hub at the University of Rwanda: Current Projects and Prospects for the Future

Jean de Dieu Hakizimana, Ph.D., African Centre of Excellence in Energy for Sustainable Development, College of Science and Technology, University of Rwanda

Global Leadership Students SDGs Project Exhibition

An exhibition of innovative solutions to the UN SDG by Global Leadership students! As part of their Global Leadership course, students work in groups to study each of the seventeen sustainable development goals, understand the components and process of a grant proposal, develop their own solutions to a specific SDG and craft a compelling proposal.

Global Leadership Students SDGs Project Exhibition

An exhibition of innovative solutions to the UN SDG by Global Leadership students! As part of their Global Leadership course, students work in groups to study each of the seventeen sustainable development goals, understand the components and process of a grant proposal, develop their own solutions to a specific SDG and craft a compelling proposal.

Sustainable-X Hangout

Learn how to become a social and environmental entrepreneur and get resources for your project. This monthly event occurs on the 4th Tuesday of every month.

Register to attend here

IDEaS Awards 2023 Seed Grants to Seven Interdisciplinary Research Teams

Oct 20, 2023 —

The teams awarded will focus on strategic new initiatives in Artificial Intelligence.

The Institute for Data Engineering and Science, in conjunction with several Interdisciplinary Research Institutes (IRIs) at Georgia Tech, have awarded seven teams of researchers from across the Institute a total of $105,000 in seed funding geared to better position Georgia Tech to perform world-class interdisciplinary research in data science and artificial intelligence development and deployment.

The goals of the funded proposals include identifying prominent emerging research directions on the topic of AI, shaping IDEaS future strategy in the initiative area, building an inclusive and active community of Georgia Tech researchers in the field that potentially include external collaborators, and identifying and preparing groundwork for competing in large-scale grant opportunities in AI and its use in other research fields.

Below are the 2023 recipients and the co-sponsoring IRIs:

Proposal Title: "AI for Chemical and Materials Discovery" + “AI in Microscopy Thrust”

PI: Victor Fung, CSE | Vida Jamali, ChBE| Pan Li, ECE | Amirali Aghazadeh Mohandesi, ECE

Award: $20k (co-sponsored by IMat)

Overview: The goal of this initiative is to bring together expertise in machine learning/AI, high-throughput computing, computational chemistry, and experimental materials synthesis and characterization to accelerate material discovery. Computational chemistry and materials simulations are critical for developing new materials and understanding their behavior and performance, as well as aiding in experimental synthesis and characterization. Machine learning and AI play a pivotal role in accelerating material discovery through data-driven surrogate models, as well as high-throughput and automated synthesis and characterization.

Proposal Title: " AI + Quantum Materials”

PI: Zhigang JIang, Physics | Martin Mourigal, Physics

Award: $20k (Co-Sponsored by IMat)

Overview: Zhigang Jiang is currently leading an initiative within IMAT entitled “Quantum responses of topological and magnetic matter” to nurture multi-PI projects. By crosscutting the IMAT initiative with this IDEAS call, we propose to support and feature the applications of AI on predictive and inverse problems in quantum materials. Understanding the limit and capabilities of AI methodologies is a huge barrier of entry for Physics students, because researchers in that field already need heavy training in quantum mechanics, low-temperature physics and chemical synthesis. Our most pressing need is for our AI inclined quantum materials students to find a broader community to engage with and learn. This is the primary problem we aim to solve with this initiative.

PI: Jeffrey Skolnick, Bio Sci | Chao Zhang, CSE

Proposal Title: Harnessing Large Language Models for Targeted and Effective Small Molecule 4 Library Design in Challenging Disease Treatment

Award: $15k (co-sponsored by IBB)

Overview: Our objective is to use large language models (LLMs) in conjunction with AI algorithms to identify effective driver proteins, develop screening algorithms that target appropriate binding sites while avoiding deleterious ones, and consider bioavailability and drug resistance factors. LLMs can rapidly analyze vast amounts of information from literature and bioinformatics tools, generating hypotheses and suggesting molecular modifications. By bridging multiple disciplines such as biology, chemistry, and pharmacology, LLMs can provide valuable insights from diverse sources, assisting researchers in making informed decisions. Our aim is to establish a first-in-class, LLM driven research initiative at Georgia Tech that focuses on designing highly effective small molecule libraries to treat challenging diseases. This initiative will go beyond existing AI approaches to molecule generation, which often only consider simple properties like hydrogen bonding or rely on a limited set of proteins to train the LLM and therefore lack generalizability. As a result, this initiative is expected to consistently produce safe and effective disease-specific molecules.

PI: Yiyi He, School of City & Regional Plan | Jun Rentschler, World Bank

Proposal Title: “AI for Climate Resilient Energy Systems”

Award: $15k (co-sponsored by SEI)

Overview: We are committed to building a team of interdisciplinary & transdisciplinary researchers and practitioners with a shared goal: developing a new framework which model future climatic variations and the interconnected and interdependent energy infrastructure network as complex systems. To achieve this, we will harness the power of cutting-edge climate model outputs, sourced from the Coupled Model Intercomparison Project (CMIP), and integrate approaches from Machine Learning and Deep Learning models. This strategic amalgamation of data and techniques will enable us to gain profound insights into the intricate web of future climate-change-induced extreme weather conditions and their immediate and long-term ramifications on energy infrastructure networks. The seed grant from IDEaS stands as the crucial catalyst for kick-starting this ambitious endeavor. It will empower us to form a collaborative and inclusive community of GT researchers hailing from various domains, including City and Regional Planning, Earth and Atmospheric Science, Computer Science and Electrical Engineering, Civil and Environmental Engineering etc. By drawing upon the wealth of expertise and perspectives from these diverse fields, we aim to foster an environment where innovative ideas and solutions can flourish. In addition to our internal team, we also have plans to collaborate with external partners, including the World Bank, the Stanford Doerr School of Sustainability, and the Berkeley AI Research Initiative, who share our vision of addressing the complex challenges at the intersection of climate and energy infrastructure.

PI: Jian Luo, Civil & Environmental Eng | Yi Deng, EAS

Proposal Title: “Physics-informed Deep Learning for Real-time Forecasting of Urban Flooding”

Award: $15k (co-sponsored by BBISS)

Overview: Our research team envisions a significant trend in the exploration of AI applications for urban flooding hazard forecasting. Georgia Tech possesses a wealth of interdisciplinary expertise, positioning us to make a pioneering contribution to this burgeoning field. We aim to harness the combined strengths of Georgia Tech's experts in civil and environmental engineering, atmospheric and climate science, and data science to chart new territory in this emerging trend. Furthermore, we envision the potential extension of our research efforts towards the development of a real-time hazard forecasting application. This application would incorporate adaptation and mitigation strategies in collaboration with local government agencies, emergency management departments, and researchers in computer engineering and social science studies. Such a holistic approach would address the multifaceted challenges posed by urban flooding. To the best of our knowledge, Georgia Tech currently lacks a dedicated team focused on the fusion of AI and climate/flood research, making this initiative even more pioneering and impactful.

Proposal Title: “AI for Recycling and Circular Economy”

PI: Valerie Thomas, ISyE and PubPoly | Steven Balakirsky, GTRI

Award: $15k (co-sponsored by BBISS)

Overview: Most asset management and recycling-use technology has not changed for decades. The use of bar codes and RFID has provided some benefits, such as for retail returns management. Automated sorting of recyclables using magnets, eddy currents, and laser plastics identification has improved municipal recycling. Yet the overall field has been challenged by not-quite-easy-enough identification of products in use or at end of life. AI approaches, including computer vision, data fusion, and machine learning provide the additional capability to make asset management and product recycling easy enough to be nearly autonomous. Georgia Tech is well suited to lead in the development of this application. With its strength in machine learning, robotics, sustainable business, supply chains and logistics, and technology commercialization, Georgia Tech has the multi-disciplinary capability to make this concept a reality; in research and in commercial application.

Proposal Title: “Data-Driven Platform for Transforming Subjective Assessment into Objective Processes for Artistic Human Performance and Wellness”

PI: Milka Trajkova, Research Scientist/School of Literature, Media, Communication | Brian Magerko, School of Literature, Media, Communication

Award: $15k (co-sponsored by IPaT)

Overview: Artistic human movement at large, stands at the precipice of a data-driven renaissance. By leveraging novel tools, we can usher in a transparent, data-driven, and accessible training environment. The potential ramifications extend beyond dance. As sports analytics have reshaped our understanding of athletic prowess, a similar approach to dance could redefine our comprehension of human movement, with implications spanning healthcare, construction, rehabilitation, and active aging. Georgia Tech, with its prowess in AI, HCI, and biomechanics is primed to lead this exploration. To actualize this vision, we propose the following research questions with ballet as a prime example of one of the most complex types of artistic movements: 1) What kinds of data - real-time kinematic, kinetic, biomechanical, etc. captured through accessible off-the-shelf technologies, are essential for effective AI assessment in ballet education for young adults?; 2) How can we design and develop an end-to-end ML architecture that assesses artistic and technical performance?; 3) What feedback elements (combination of timing, communication mode, feedback nature, polarity, visualization) are most effective for AI- based dance assessment?; and 4) How does AI-assisted feedback enhance physical wellness, artistic performance, and the learning process in young athletes compared to traditional methods?

- Christa M. Ernst

Christa M. Ernst | Research Communications Program Manager

Robotics | Data Engineering | Neuroengineering

christa.ernst@research.gatech.edu