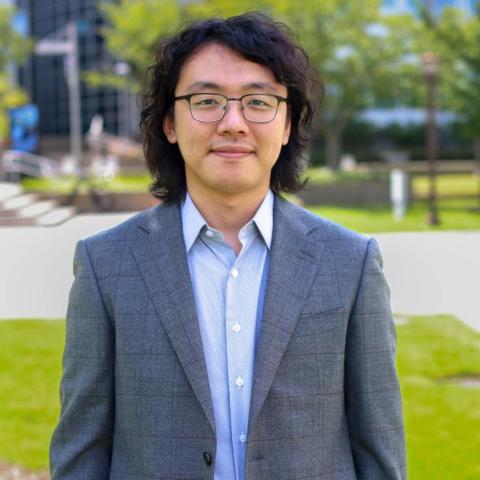

Dr. Yeo holds the titles of G.P. "Bud" Peterson and Valerie H. Peterson Endowed Professor, as well as Harris Saunders Jr. Endowed Professor, in the Woodruff School of Mechanical Engineering and the Coulter Department of Biomedical Engineering at Georgia Tech. He is also the director of the Wearable Intelligent Systems and Healthcare Center (WISH Center) and the KIAT-Georgia Tech Semiconductor Electronics Center (K-GTSEC). Dr. Yeo's research focuses on understanding the fundamentals of soft materials, deformable mechanics, interfacial physics, manufacturing, and the integration of hard and soft materials for the development of biomedical systems. He earned his Ph.D. in mechanical engineering and genome sciences from the University of Washington in Seattle and subsequently worked as a postdoctoral research fellow at the University of Illinois at Urbana-Champaign. With over 180 peer-reviewed publications, Dr. Yeo has contributed to many prestigious journals, including Nature Materials, Nature Machine Intelligence, Nature Communications, and Science Advances. He is an IEEE Senior Member and has received numerous awards, including the Visiting Professorship from the Institute Jean Lamour at the Université de Lorraine in France, the Lucy G. Moses Lectureship Award at the Mount Sinai School of Medicine, the NIH Trailblazer Young Investigator Award, the IEEE Outstanding Engineer Award, the Emory School of Medicine Research Award, the Imlay Innovation Award, the American Heart Association Innovative Project Award, the Sensors Young Investigator Award, the Med-X Young Investigator Award, and the Outstanding Service Award from the Korea Institute for Advancement of Technology, as well as the Outstanding Yonsei Scholar Award. Dr. Yeo is also the founder of two startup companies: Huxley Medical, Inc. and WisMedical, Inc.

Faculty, Wallace H. Coulter Department of Biomedical Engineering

Additional Research

Human-machine interface; hybrid materials; bio-MEMS; Soft robotics. Flexible Electronics; Human-machine interface; hybrid materials; Electronic Systems, Devices, Components, & Packaging; bio-MEMS; Soft robotics. Yeo's research in the field of biomedical science and bioengineering focuses on the fundamental and applied aspects of biomolecular interactions, soft materials, and nano-microfabrication for the development of nano-biosensors and soft bioelectronics.