Is the whole universe just a simulation? – Moumita B., age 13, Dhaka, Bangladesh

How do you know anything is real? Some things you can see directly, like your fingers. Other things, like your chin, you need a mirror or a camera to see. Other things can’t be seen, but you believe in them because a parent or a teacher told you, or you read it in a book.

As a physicist, I use sensitive scientific instruments and complicated math to try to figure out what’s real and what’s not. But none of these sources of information is entirely reliable: Scientific measurements can be wrong, my calculations can have errors, even your eyes can deceive you, like the dress that broke the internet because nobody could agree on what colors it was.

Because every source of information – even your teachers – can trick you some of the time, some people have always wondered whether we can ever trust any information.

If you can’t trust anything, are you sure you’re awake? Thousands of years ago, Chinese philosopher Zhuangzi dreamed he was a butterfly and realized that he might actually be a butterfly dreaming he was a human. Plato wondered whether all we see could just be shadows of true objects. Maybe the world we live in our whole lives inside isn’t the real one, maybe it’s more like a big video game, or the movie “The Matrix.”

The Simulation Hypothesis

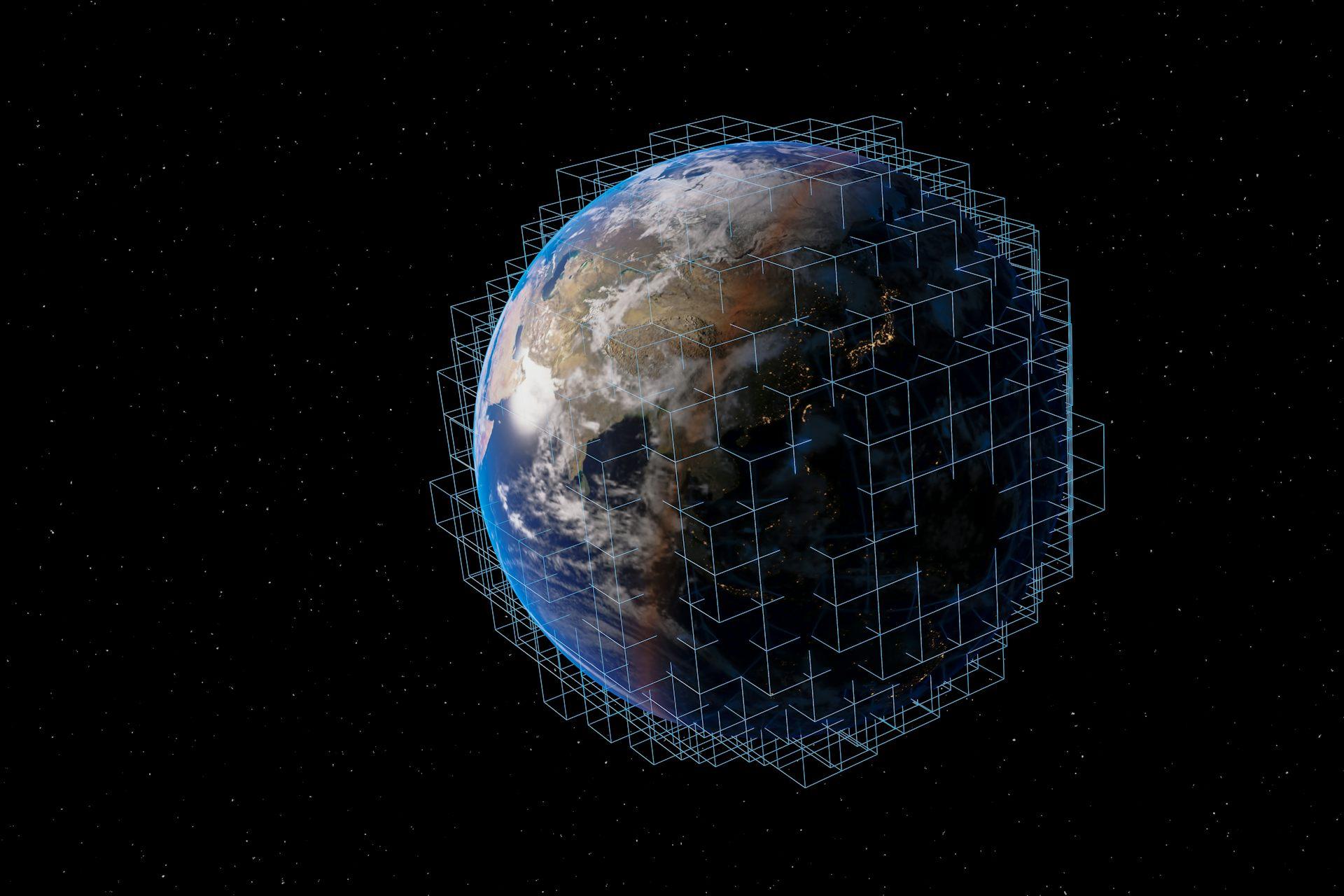

The simulation hypothesis is a modern attempt to use logic and observations about technology to finally answer these questions and prove that we’re probably living in something like a giant video game. Twenty years ago, a philosopher named Nick Bostrom made such an argument based on the fact that video games, virtual reality and artificial intelligence were improving rapidly. That trend has continued, so that today people can jump into immersive virtual reality or talk to seemingly conscious artificial beings.

Bostrom projected these technological trends into the future and imagined a world in which we’d be able to realistically simulate trillions of human beings. He also suggested that if someone could create a simulation of you that seemed just like you from the outside, it would feel just like you inside, with all of your thoughts and feelings.

Suppose that’s right. Suppose that sometime in, say, the 31st century, humanity will be able to simulate whatever they want. Some of them will probably be fans of the 21st century and will run many different simulations of our world so that they can learn about us, or just be amused.

Here’s Bostrom’s shocking logical argument: If the 21st century planet Earth only ever existed one time, but it will eventually get simulated trillions of times, and if the simulations are so good that the people in the simulation feel just like real people, then you’re probably living on one of the trillions of simulations of the Earth, not on the one original Earth.

This argument would be even more convincing if you actually could run powerful simulations today, but as long as you believe that people will run those simulations someday, then you logically should believe that you’re probably living in one today.

Signs We’re Living in a Simulation …Or Not

If we are living in a simulation, does that explain anything? Maybe the simulation has glitches, and that’s why your phone wasn’t where you were sure you left it, or how you knew something was going to happen before it did, or why that dress on the internet looked so weird.

There are more fundamental ways in which our world resembles a simulation. There is a particular length, much smaller than an atom, beyond which physicists’ theories about the universe break down. And we can’t see anything more than about 50 billion light-years away because the light hasn’t had time to reach us since the Big Bang. That sounds suspiciously like a computer game where you can’t see anything smaller than a pixel or anything beyond the edge of the screen.

Of course, there are other explanations for all of that stuff. Let’s face it: You might have misremembered where you put your phone. But Bostrom’s argument doesn’t require any scientific proof. It’s logically true as long as you really believe that many powerful simulations will exist in the future. That’s why famous scientists like Neil deGrasse Tyson and tech titans like Elon Musk have been convinced of it, though Tyson now puts the odds at 50-50.

Others of us are more skeptical. The technology required to run such large and realistic simulations is so powerful that Bostrom describes such simulators as godlike, and he admits that humanity may never get that good at simulations. Even though it is far from being resolved, the simulation hypothesis is an impressive logical and philosophical argument that has challenged our fundamental notions of reality and captured the imaginations of millions.

Hello, curious kids! Do you have a question you’d like an expert to answer? Ask an adult to send your question to CuriousKidsUS@theconversation.com. Please tell us your name, age and the city where you live.

And since curiosity has no age limit – adults, let us know what you’re wondering, too. We won’t be able to answer every question, but we will do our best.![]()

This article is republished from The Conversation under a Creative Commons license. Read the original article.