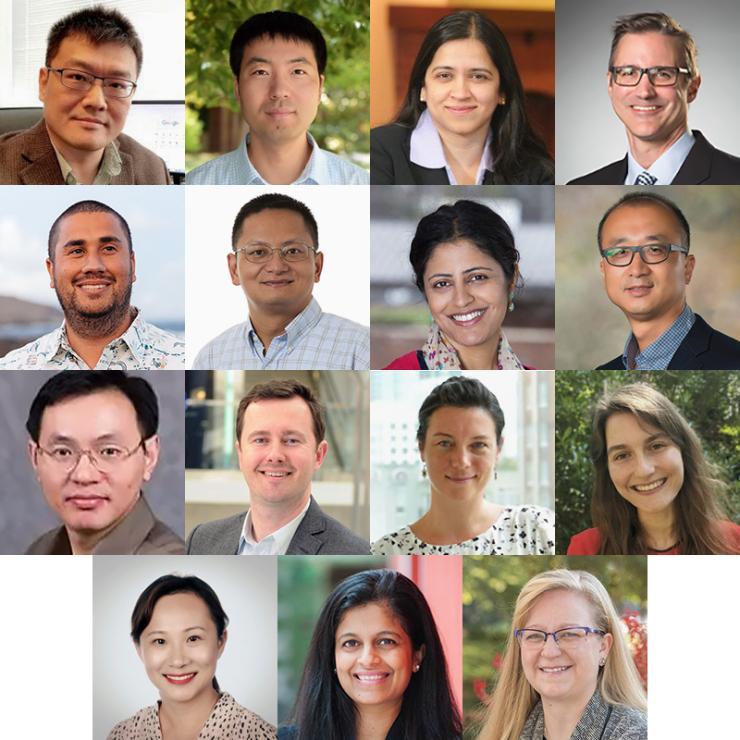

BBISS Initiative Leads Projects Selected

Feb 09, 2023 — Atlanta, GA

From L to R: Hailong Chen, Yi Deng, Shatakshee Dhongde, Michael Helms, Josiah Hester, Xiaoming Huo, Neha Kumar, Junshan Liu, Jian Luo, Alex Oettl, Dori Pap, Brigitte Stepanov, Yuanzhi Tang, Anjali Thomas, and Danielle Willkens.

Ten projects have been chosen for the Brook Byers Institute for Sustainable Systems (BBISS) Initiative Leads program. Project themes include climate adaptation and mitigation solutions, innovation and social impact, computation and design approaches to sustainability, sustainable development, and conservation. BBISS Initiative Leads receive $10,000 in discretionary funds to advance their project.

The projects chosen involve 15 faculty members hailing from all 6 of the colleges at Georgia Tech. Several of the projects are also joint initiatives with other Georgia Tech Interdisciplinary Research Institutes (IDEAS, IPAT, and SEI), the Ray C. Anderson Center for Sustainable Business, or the Office of Sustainability.

The Initiative Leads and projects are:

- Michael Helms - ME, “Nature’s Voice: Amplifying the Narrative of Biologically Inspired Sustainable Design at Georgia Tech”

- Josiah Hester - Interactive Computing, “Computational Sustainability”

- Co-Leads Xiaoming Huo - ISYE, and Yi Deng – EAS, “Microclimate Monitoring and Prediction at Georgia Tech”

- Jian Luo - CEE, “Coastal Urban Flooding in a Changing Climate”

- Brigitte Stepanov - Modern Languages, “Energy Today, Tomorrow: Illuminating the Effect of Energy Power Dynamics on the Environment”

- Co-Leads Anjali Thomas – INTA, and Shatakshee Dhongde - ECON, “SEEDS (Southeast Exchange of Development Studies) 2023 Conference at Georgia Tech”

- Co-Leads Danielle Willkens - Arch, and Junshan Liu – Auburn University, “Sustainable Tourism, Petra”

- Co-Leads Yuanzhi Tang - EAS, and Hailong Chen – ME, “Sustainable Resources for Clean Energy”

- Co-Leads Dori Pap - Institute for Leadership and Social Impact, and Neha Kumar – Interactive Computing/INTA, “Collaborative Social Impact”

- Alex Oettl - COB, “A Sustainability-Focused Stream of the Creative Destruction Lab”

The Initiative Leads program has several overarching goals. BBISS aims to cultivate promising topics for future large-scale collaborative sustainability research, research translation, and/or high-impact outreach; to provide (mostly mid-career) faculty with leadership and community building opportunities; and to broaden and strengthen the BBISS sustainability community as a whole.

Brent Verrill, Research Communications Program Manager, BBISS

Conversations with Cabrera: Climate Action

President Ángel Cabrera convenes a panel of faculty to discuss climate action as part of Sustainable Development Goals Action and Awareness Week. Joining him will be:

The Plants Seeking Refuge Across Our Dynamically Changing Planet

Feb 07, 2023 — Atlanta, GA

Along the highest peaks in North Carolina, an isolated spruce-fir boreal forest stands as a relict of the Pleistocene, contrasting with deciduous trees on the Southern Appalachians. (Photo: Mount Mitchell State Park by Jess Hunt-Ralston, Georgia Tech)

Plants, like animals and people, seek refuge from climate change. And when they move, they take entire ecosystems with them. To understand why and how plants have trekked across landscapes throughout time, researchers at the forefront of conservation are calling for a new framework. The key to protecting biodiversity in the future may be through understanding the past.

Jenny McGuire, assistant professor in the Schools of Biological Sciences and Earth and Atmospheric Sciences at Georgia Tech, spearheaded a special feature on the topic of biodiversity in The Proceedings of the National Academy of Sciences along with colleagues in Texas, Norway, and Argentina. In the special feature, “The Past as a Lens for Biodiversity Conservation on a Dynamically Changing Planet,” McGuire and her collaborators highlight the outstanding questions that must be addressed for successful future conservation efforts. The feature brings together conservation research that illuminates the complex and constantly evolving dynamics brought on by climate change and the ever-shifting ways humans use land. These factors, McGuire said, interact over time to create dynamic changes and illustrate the need to incorporate temporal perspectives into conservation strategies by looking deep into the past.

One example of this work highlighted in the journal is McGuire’s research about plants in North America, which investigates how and why they’ve moved across geography over time, where they’re heading, and why it’s important.

“Plants are shifting their geographic ranges, and this is happening whether we realize it or not,” McGuire said. “As seeds fall or are transported to distant places, the likelihood that the plant’s seed is going to be able to survive and grow is changing as climates are changing. Studying plants’ niche dynamics over thousands of years can help us understand how species adapt to climate change and can teach us how to protect and maintain biodiversity in the face of rapid climate change to come.”

Climate Fidelity: A New Metric for Understanding Vulnerability

The first step is to understand which type of plants exhibit what McGuire terms “climate fidelity,” and which do not. If a plant has climate fidelity, it means that the plant stays loyal to its preferred climatic niche, often migrating across geographies over thousands of years to keep up with its ideal habitat. Plants that don’t exhibit climate fidelity tend to adapt locally in the face of climate change. Being loyal to one’s climate, it turns out, doesn’t necessarily mean being loyal to a particular place.

To investigate the case of trees, McGuire and former Georgia Tech postdoctoral scholar Yue Wang (associate professor in the School of Ecology at Sun Yat-sen University in China) studied pollen data from the Neotoma Paleoecology Database, which contains pollen fossil data from sediment cores across North America. Each sediment core is sampled, layer by layer, producing a series of pollen data from different times throughout history. The data also contains breakdowns of the relative abundance of different types of plants represented by the pollen types – pine versus oak versus grass, for example – painting a picture of what types of plants were present in that location and when.

McGuire and Wang looked at data from 13,240 fossil pollen samples taken from 337 locations across the entirety of North America. For each of the 16 major plant taxa in North America, they divided the pollen data into six distinct chunks or “bins” of time of 4,000 years, starting from 18,000 years ago up to the present day. Wang used the data to identify all climate sites containing fossil pollen for any individual type of tree – such as oak, for example – for each period. Then, Wang looked at how each tree’s climate changed from one period to the next. Wang did this by comparing the locations of pollen types between adjacent time periods, which enabled the team to identify how and why each type of tree’s climate changed over time.

“This process allowed us to see the climate fidelity of these different plant taxa, showing that certain plants maintain very consistent climatic niches, even when climate is changing rapidly,” Wang said.

For example, their findings showed that when North American glaciers were retreating 18,000 years ago, spruce and alder trees moved northward to maintain the cool temperatures of their habitats.

Crucially, McGuire and Wang found that most plant species in North America have exhibited long-term climate fidelity over the past 18,000 years. They also found that plants that migrated farther did a better job of tracking climate during periods of change.

But some plants fared better than others. For example, the small seeds of willow trees can fly over long distances – enabling them to track their preferred climates very effectively. But the large seeds of ash trees, for example, can only be dispersed short distances from parent trees, hindering their ability to track climate. Habitat disruptions from humans could make it even more difficult for ash trees to be able to take hold in new regions. If there are no adjacent habitats for ash trees, their seeds are under pressure to move even farther – a particular challenge for ash, which slows their migration movements even more.

Protecting the Fabric of Life

On the bright side, by identifying which plants have historically been most sensitive to changing climates, McGuire and Wang’s research can help conservation organizations like The Nature Conservancy prioritize land where biodiversity is most vulnerable to climate change.

As a final step, McGuire and Wang identified “climate fidelity hotspots,” regions that have historically exhibited strong climate fidelity whose plants will most urgently need to move as their climates change. They compared these hotspots to climate-resilient regions identified by The Nature Conservancy that could serve as refuge areas for those plants. While plants in these resilient regions can initially adapt to impending climate change by shifting their distributions locally, the plants will likely face major challenges when a region’s climate change capacity is exceeded due to lack of connectivity and habitat disruptions from humans. Refining these priorities helps stakeholders identify efficient strategies for allowing the fabric of life to thrive.

“I think that understanding climate fidelity, while a new and different idea, will be very important going forward, especially when thinking about how to prioritize protecting different plants in the face of climate change,” McGuire said. “It is important to be able to see that some plants and animals are more vulnerable to climate change, and this information can help build stronger strategies for protecting the biodiversity on the planet.”

Citation: Yue Wang, Silvia Pineda-Munoz, and Jenny L. McGuire, "Plants maintain climate fidelity in the face of dynamic climate change." PNAS (2023).

DOI: doi.org/10.1073/pnas.2201946119

Georgia Tech assistant professor Jenny McGuire (right) and Dr. Yue Wang.

Catherine Barzler, Senior Research Writer/Editor

Sustainable-X Showcase

Come celebrate our entrepreneurs that are passionate about creating start ups with environmental and social impact. The showcase will provide participants the chance to show off their ideas. Top three submissions will win cash prizes and the chance to join the CREATE-X Startup Launch program in the summer.

Interested in presenting at the Showcase? The deadline to register is March 7, 2023. Finalists will be notified on March 10.

Atlanta Conference on Science and Innovation Policy

The 9th Biennial Atlanta Conference on Science and Innovation Policy will be held May 24 –26 at the Georgia Institute of Technology Global Learning Center in Atlanta.

Business, Environment, and Society Speaker Series: Environment, Social, Governance (ESG) - "Trends, Challenges, and Opportunities"

The Ray C. Anderson Center for Sustainable Business invites you to join us for our panel, "Environmental, Social, Governance (ESG): Trends, Challenges, and Opportunities" which will examine how the ESG Framework is creating innovation in companies and how it is being captured in their bottom line in the Business, Environment, and Society Speaker Series.

Speakers:

Sustainable Cities Minor Information Session

The minor in Sustainable Cities emphasizes sustainability, community engagement, and social justice. It provides students with a deep learning experience that integrates classroom learning and real-world, community-based project experience in creating sustainable communities, with a focus on the built urban environment.

The minor is affiliated with Serve-Learn-Sustain.

12th Annual Southeastern Pediatric Research Conference - “Optimizing Health across the Lifespan through Innovation, Discovery, and Equity”

Submit Abstracts Here (by April 1)

Parking and Transportation Services Launches New Hybrid Bus

Jan 23, 2023 — Atlanta, GA

The Division of Student Engagement and Well-Being is excited to welcome a new hybrid Stinger bus to campus. The EZ Rider II was unveiled this week and added to the Gold Route as Georgia Tech Parking and Transportation Services (PTS) takes another step toward decreasing its carbon footprint by reducing greenhouse gas emissions.

According to senior director of PTS, Sherry Davidson, “Our transportation team took a hard look at how we could build the future that we all wanted to see. The result was changing the way in which we operate. Moving to hybrid improves sustainability while maintaining fiscal responsibility.”

PTS is continually looking for ways to reduce its environmental impact, and this new bus is a significant step in that direction. One of the key advantages is its zero-emission electric mode, which allows the bus to operate fully electric for about 20% of the route. This not only helps to improve air quality but also reduces noise pollution.

“Hybrid” means that this new bus can switch between electric and gasoline power as needed, reducing emissions and increasing fuel efficiency. It also features advanced technologies such as regenerative braking, which captures energy normally lost during braking and uses it to recharge the bus's batteries. This not only improves fuel economy but also extends the life of the bus's braking system.

This new bus will also allow PTS to improve the customer experience and the efficiency of the overall transportation system. It also features automated passenger counters, automated stop announcements, and bike racks, and its low floor ramp will improve accessibility and ease of boarding for passengers.

This new addition to the Gold Route is the first of nine hybrid buses to come to the Georgia Tech campus. The remaining fleet will arrive in April.

Student Engagement and Well-Being

Alumni “Careers in Sustainability” Advisement Hour

Join Scheller Undergraduate and MBA sustainable business alumni and career advisors for this virtual drop-in event to chat about sustainability in your career field and ways to increase competitive advantage in the job market. The discussion is open to current students who are interested in infusing sustainability into their careers. Zoom link is available in the RSVP form.