Community Garden to Unveil Expansion Friday

Apr 19, 2023 —

Bird's eye view of the expanded Community Garden

As Georgia Tech continues to celebrate Earth Month, Friday's ribbon-cutting ceremony for the newly expanded Community Garden represents another step in the Institute's commitment to a sustainable future.

First opened in 2012 with six small planting beds, the garden has received a complete transformation over the past decade. With the latest project, which began in July 2022, essentially doubling its square footage, the garden now touts 21 fruit trees and nine large beds that are free and open to students. Two additional medium and nine small beds are available for lease for the Tech community. A new shed for gardening tools has been constructed alongside a brand-new demo kitchen to feature the garden's produce in healthy recipes. With the inclusion of slate-chip pathways and high-density mulch, the garden is now fully ADA accessible — a primary goal of the expansion effort.

Elias Winterscheidt was drawn to the garden while touring the Tech campus in 2019. With prior planting experience, he immediately got involved with Students Organizing for Sustainability (SOS), taking over as the Community Garden director in April 2021. Over the past three semesters before construction began, the garden donated 50 pounds of produce to Klemis Kitchen — Georgia Tech's on-campus food bank — in addition to the produce harvested by 500 volunteers during that time.

Winterscheidt anticipates the growth of the garden community continuing, with hopes of doubling both donations to Klemis Kitchen and the number of volunteers.

SOS got a head start on its goal at the outset of Earth Month, when Winterscheidt and a group of volunteers planted the first seeds in the expanded garden during a pair of community workdays. Sweet potatoes, tomatoes, strawberries, and various seeds are already in the ground, but plenty more fruits, vegetables, and herbs will be added soon.

In addition to a passion for gardening, Winterscheidt arrived at Tech at a time when many students were seeking ways to get outside during the pandemic. A lasting effect of the interruption has been an increase in the number of virtual events, but the garden provides the perfect opportunity to interact with nature and with other people.

"We're trying to get people to come outside. Our goal is to get Georgia Tech students away from their computers, away from their homework, and to de-stress and get their hands in the soil," he said, adding that the workdays give students a chance to interact with others from different majors and backgrounds. "Come for a few hours, chat with people, and after two hours, you feel refreshed. It's a kind of group therapy."

Community workdays in the garden are typically held on Saturday mornings, depending on the weather.

Beginning with summer programming, SOS will partner with the Wellness Empowerment Center to highlight the mental and physical health benefits of gardening. They will also be emphasizing sustainability. The Community Garden is entirely permaculture friendly, meaning it's a pesticide-free environment, and seeds are planted with purpose.

"We're mimicking nature in how we plant things," Winterscheidt explained. “Rather than spraying with pesticide, I can plant a basil plant that will deter hornworms from our tomatoes. Rather than spraying with herbicides, we can pluck all the weeds off individually. It takes a lot longer, but it's much better for our soil. Rather than growing for maximum output, we're growing in a way that benefits our soil the most."

While largely student-run, the garden does require constant upkeep, so in years past, the summer months could be challenging. However, with the expansion, Tamsin Leavy has been brought on as staff member to support the garden year-round.

"Like any garden or farm space, you don't want to lose all your hard work to the elements or other pests that can quickly annihilate a crop. We have put a lot of effort into this space and are looking forward to watching it grow. No pun intended," Leavy said. "It would be devastating to lose it to the harsh Georgia summer sun, so we will all be working together to keep our garden growing."

Volunteer opportunities remain plentiful over the summer, and in the absence of a large contingent of students, Malte Weiland, senior sustainability project manager for Campus Services, welcomes Tech faculty and staff to lend a hand. He encouraged all Tech employees to reach out to assist the team in maintaining the space and even urges entire departments to inquire about outings that can serve as wellness and team-building exercises.

For those looking to get involved with the garden or learn more about its expansion, Friday's ribbon-cutting ceremony will begin at 2 p.m.

“We all hope that the garden will continue to be a community gathering space where not just horticultural and agricultural education can happen, but anything adjacent to it — discussion on composting, urban gardens, or food justice issues. And day-to-day, for Tech students, I hope it can be a space where they are comfortable, where they can come to smell the flowers, put their hands in the dirt — even if it's just for a few minutes between classes to de-stress and reconnect to the earth," Leavy said.

The Community Market is another resource that brings sustainably sourced food to the Tech community every Wednesday from 10 a.m. to 2 p.m. along Tech Walkway. The Office of Sustainability will wrap up the spring semester market at the end of April, but selective summer dates will be announced soon. When the market returns in the fall, Weiland said that vendors and patrons can expect several updates, including a market map, and students will be able to make purchases using dining dollars on their BuzzCards.

Tomato plants in the new community garden.

Elias Winterscheidt waters trees in the Community Garden

Demo kitchen inside the Community Garden

The Community Garden prior to its expansion.

Steven Gagliano - Communications Officer

Institute Communications

School of Physics Public Lecture - Professor Steven Chu: Climate Change and innovative paths towards a more sustainable future

On behalf of the Georgia Tech College of Sciences and the School of Physics, we invite you to join us and our esteemed guest Professor Steven Chu, former U.S. Secretary of Energy and co-recipient of the 1997 Nobel Prize in Physics.

Speaker: Prof. Steven Chu

Host: Prof. Dan Goldman

Tool Helps Coastal Areas Find Ideal Spots for Water Level Sensors

Apr 13, 2023 —

An aerial view of the Tybee Island marina in Chatham County, Georgia.

As climate change leads to rising sea levels and more powerful storms, coastal communities increasingly are turning to networks of sensors to track water levels. The sensors — which are progressively getting cheaper and more capable — can help officials anticipate flood risks and respond in emergencies.

A tool developed by Georgia Tech researchers can help make the most of those networks, pinpointing the ideal locations for water level sensors to maximize the real-time data available to emergency managers.

In a test case in Chatham County, Georgia, the approach developed by civil engineer Iris Tien reduced 29,000 potential sensor locations to just 381. The idea, then, is that officials can use their local expertise and historical knowledge to pick where to install sensors among those spots.

Joshua Stewart

College of Engineering

Urban Air Quality in the Age of Climate Change: A IHE-LeaD Symposium and Workshop

Are you interested in expanding your communication and outreach skills? Is your research looking at environmental health? We have a wonderful event opportunity for you to engage in!

Workshop registration is now open for the IHE-LeaD symposium “Urban Air Quality in the Age of Climate Change," an interactive event connecting researchers, public leaders, and community advocates to discuss urban air quality and its consequences for human health, equity, and the environment.

Rising Temperatures Alter ‘Missing Link’ of Microbial Processes, Putting Northern Peatlands at Risk

Mar 31, 2023 —

An aerial view of the SPRUCE enclosure.

If you’re an avid gardener, you may have considered peat moss — decomposed Sphagnum moss that helps retain moisture in soil — to enhance your home soil mixture. And while the potting medium can help plants thrive, it’s also a key component of peatlands: wetlands characterized by a thick layer of water-saturated, carbon-rich peat beneath living Sphagnum moss, trees, and other plant life.

These ecosystems cover just 3% of Earth’s land area, but “peatlands store over one-third of all soil carbon on the planet,” explains Joel Kostka, professor and associate chair of Research in the School of Biological Sciences at Georgia Tech.

This carbon storage is supported in large part by microbes. Two microbial processes in particular — nitrogen fixation and methane oxidation — strike a delicate balance, working together to give Sphagnum mosses access to critical nutrients in nutrient-depleted peatlands.

The coupling of these two processes is often referred to as the “missing link” of nutrient cycling in peatlands. Yet, how these processes will respond to changing climates along northern latitudes is unclear.

“There are tropical peatlands — but the majority of peatlands are in northern environments.” notes Caitlin Petro, a research scientist who works with Kostka in Biological Sciences at Tech. “And those are going to be hit harder by climate change.”

Kostka and Petro recently led a collaborative study to investigate how this critical type of ecosystem (and the “missing link” of microbial processes that support it) may react to the increased temperature and carbon dioxide levels predicted to come with climate change. The team, which also includes researchers from the Oak Ridge National Laboratory (ORNL), Florida State University, and the University of Tennessee, Knoxville, just published their work in the scientific journal Global Change Biology.

By testing the effects of increasing temperature and carbon dioxide on the growth of Sphagnum moss, its associated microbiome, and overall ecosystem health, Kostka and Petro say computational models will be better equipped to predict the effects of climate change.

“Down the road,” Kostka added, “we hope the results can be used by environmental managers and governments to adaptively manage or geoengineer peatlands to thrive in a warmer world.”

Raising the heat

To see how northern peatlands will react to climate change, the team, which also included School of Earth and Atmospheric Sciences Associate Professor Jennifer Glass, turned to the ORNL Spruce and Peatland Responses Under Changing Environments (SPRUCE) experiment — a unique field lab in northern Minnesota where the team warms peat bogs and experimentally changes the amount of carbon dioxide in the atmosphere.

Starting in 2016, the team exposed different parts of SPRUCE’s experimental peatlands to a gradient of higher temperatures ranging from an increase of 0°C to 9°C, capturing the Intergovernmental Panel on Climate Change models’ predicted 4°C to 6°C increase in northern regions by 2100.

The moss’s reaction was significant. Although nearly 100% of the bog’s surface was covered in moss at the beginning of the experiment, moss coverage dropped with each increase in temperature, plummeting to less than 15% in the warmest conditions.

Critically, the two microbial processes that had previously been consistently linked fell out of sync at higher temperatures.

“Peatlands are extremely nutrient-poor and microbial nitrogen fixation represents a major nitrogen input to the ecosystem,” Kostka explained. Fixing nitrogen is the process of turning atmospheric nitrogen into an organic compound that the moss can use for photosynthesis, while methane oxidation allows the moss to use methane released from decomposing peat as energy. “Methane oxidation acts to fuel nitrogen fixation while scavenging a really important greenhouse gas before it is released to the atmosphere. This study shows that these two processes, which are catalyzed by the Sphagnum microbiome, become disconnected as the moss dies.”

“These processes occurring together are really important for the community,” Petro explained. Yet many microbes that are able to both fix nitrogen and oxidize methane were absent in the mosses collected from higher temperature enclosures. And while elevated carbon dioxide levels appeared to offset some of the changes in nitrogen cycling caused by warming, the decoupling of these processes remained.

“These treatments are altering a fairly well-defined and consistent plant microbiome that we find in many different environments, and that has this consistent function,” Petro explained. “It's like a complete functional shift in the community.”

Though it’s not clear which of these changes — the moss dying or the altered microbial activity — is driving the other, it is clear that with warmer temperatures and higher carbon dioxide levels comes a cascade of unpredictable outcomes for peat bogs.

“In addition to the direct effects of climate warming on ecosystem function,” Petro adds, “it will also introduce all of these off-shooting effects that will impact peatlands in ways that we didn't predict before.”

This work was supported by the National Science Foundation (DEB grant no. 1754756). The SPRUCE project is supported by the U.S. Department of Energy's Office of Science, Biological, and Environmental Research (DOE BER) and the USDA Forest Service.

DOI: https://doi.org/10.1111/gcb.16651

Citation: Petro, C., et al. Climate drivers alter nitrogen availability in surface peat and decouple N2 fixation from CH4 oxidation in the Sphagnum moss microbiome. Global Change Biology. (2023).

Aerial Photo: Hanson, P.J., M.B. Krassovski, and L.A. Hook. 2020. SPRUCE S1 Bog and SPRUCE Experiment Aerial Photographs. Oak Ridge National Laboratory, TES SFA, U.S. Department of Energy, Oak Ridge, Tennessee, U.S.A. https://doi.org/10.3334/CDIAC/spruce.012 (UAV image number 0050 collected on October 4, 2020).

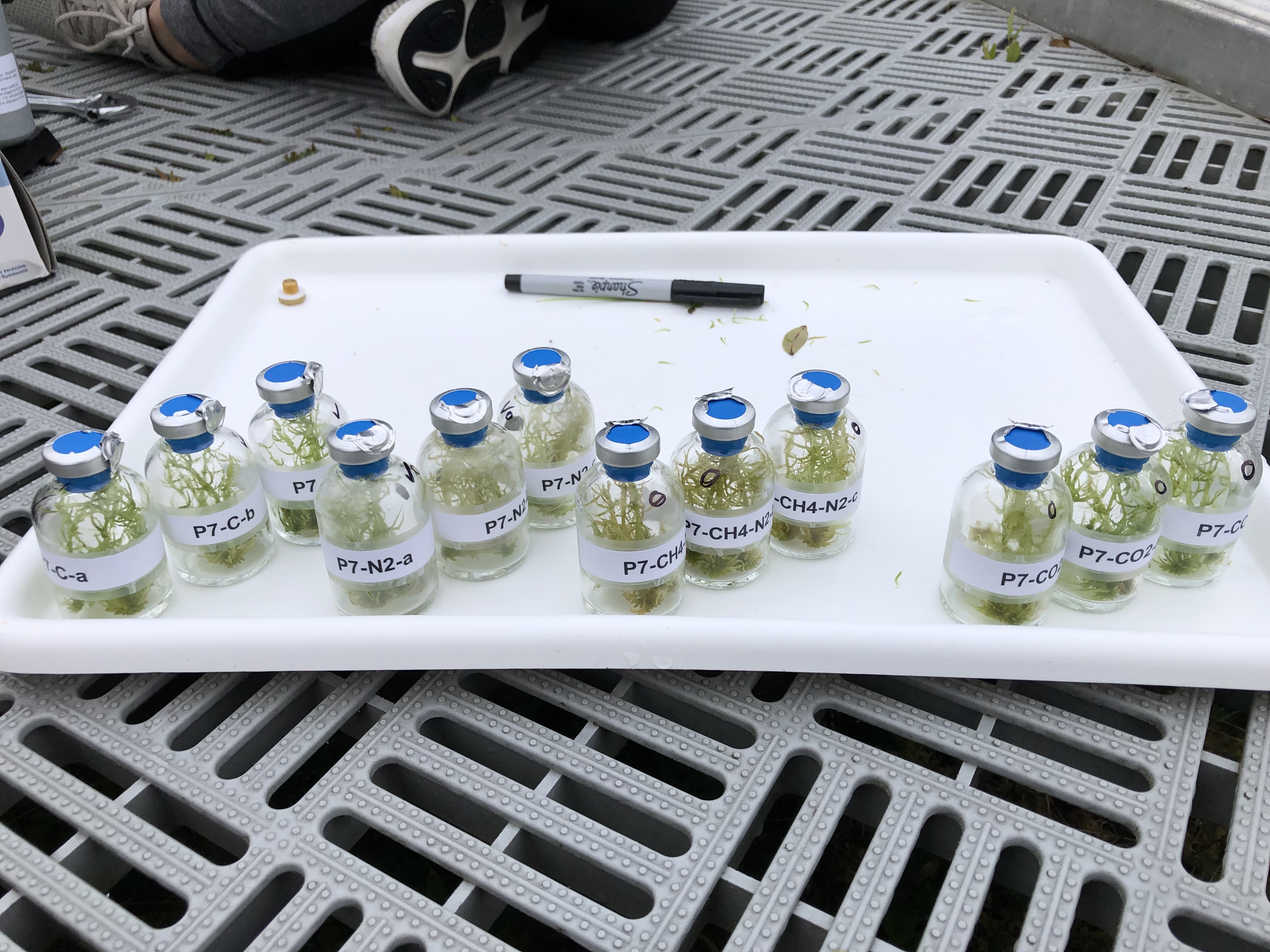

Sphagnum mosses were taken from different SPRUCE enclosures and incubated in glass jars for the study (Photo Jennifer Glass).

A closeup of a member of the research team holding Sphagnum moss, one of the key drivers of carbon sequestration in peatlands. (Photo Jennifer Glass).

Writer: Audra Davidson

Communications Officer II, College of Sciences

Editor: Jess Hunt-Ralston

Director of Communications, College of Sciences

Georgia Tech Earth Month Events to Mark on Your Calendar

Mar 30, 2023 —

On April 22, communities across the U.S. and countries around the globe will come together in observance of Earth Day. Georgia Tech takes the opportunity to educate and celebrate the importance of protecting the environment a step further with Earth Month.

Events throughout the month allow students, faculty, and staff to familiarize themselves with sustainability efforts being put forward by the Institute and practices they can incorporate into their daily routines.

The global theme for Earth Day 2023 — the 53rd iteration of the event — and Tech’s month-long rendition is “invest in our planet.”

“The Earth Month lineup highlights the numerous ways that community members can embrace this theme,’” said Abby Bower, sustainability program support coordinator. “Today, the planet faces daunting challenges, but we all have the opportunity to pitch in to solve them. Georgia Tech has many great organizations, departments, and individuals dedicating their time and resources to making a better world, and we are excited to highlight them all month long.”

During Earth Month, you can participate in service opportunities, attend educational events, weigh in on ways Georgia Tech can meet our climate goals, and more.

Tech Beautification Day

April 1, 8:30 a.m. – 12:30 p.m., The Kendeda Building for Innovative Sustainable Design

The kickoff event for Earth Month, organized by the undergraduate Student Government Association and Georgia Tech Greek Week, will see hundreds of volunteers completing projects all over campus. After a welcome breakfast, groups of eight to 10 will be assigned a task with the goal of keeping the Georgia Tech campus as picturesque as ever. With assistance from Georgia Tech Landscaping, projects include planting flowers, trees, and shrubs; pulling weeds; and spreading pine straw. A primary goal of this year’s event is to plant 200 native azaleas.

For registration and additional information, click here.

Earth Day Clothing Swap at The Kendeda Revolving Closet

April 3 -7, 9 a.m. – 4 p.m., Basement of The Kendeda Building

Sustainable fashion is a pillar of this year’s global event. According to earthday.org, 87% of the 150 billion garments produced by the fashion industry each year eventually end up in landfills, and just 1% of discarded clothing is recycled. This weeklong event is a chance to donate gently used, clean clothes and recycle torn clothes and textiles.

Earth Day Bird Walk

April 5, 8:30 a.m. – 10 a.m., The Kendeda Building

The 400-acre Tech campus is home to diverse wildlife populations, including many species of birds. Learn more about the region’s birds from an expert guide during the Bird Walk organized by The Kendeda Building and Georgia Audubon Society. The reintroduction of native plants around Kendeda has created a habitat for birds, and the adjoining EcoCommons is part of a wildlife sanctuary certified by the Georgia Audubon, making Tech the first main campus in the state to receive the designation.

For registration and additional information, click here.

Southern Energy Conference

April 7, 9:30 a.m. – 2 p.m., Bill Moore Student Success Center

With the theme of “building blocks for a zero-carbon future,” the Energy Club will host the conference featuring keynote speakers, company demos, and panels discussing the technology and economics behind the future of the energy sector. Students are invited to compete in the Energy Research Poster Competition with cash prizes on the line.

For registration and additional information, click here.

EcoReps Earth Month Celebration

April 11, 1 – 3 p.m., West Village Dining Commons

Hosted by the 2022-23 EcoReps, this event is a celebration of all things sustainability in Housing and Residence Life, highlighting recent successes such as the Energy Competition, the ECGO app, and its growing composting program.

For additional information, click here.

Earth Month Bike Ride

April 11, 4:30 – 6 p.m., Meet on the Front Lawn of the Campus Recreation Center (CRC)

Hosted by the CRC, the leisurely 7-mile, no-drop ride promotes an alternate form of transportation and a healthy lifestyle. The ride will begin with a welcome from noted bike enthusiast President Ángel Cabrera and provide an overview of infrastructure projects that are making campus increasingly rider-friendly from Institute Landscape Architect Jason Gregory.

Registration and completion of a waiver are required. Riders are strongly encouraged to wear a helmet. Tech students, faculty, and staff can get a free helmet by completing the online Ride Smart Bike/Scooter Safety class.

For registration information, click here.

Propel ATL City Cycling Class - Georgia Tech Community

April 13, 4 – 5 p.m.

Propel Atlanta invites the Georgia Tech community to learn the rules of cycling during this instructional group ride. Participants will practice skills in a safe and supportive environment.

After getting the hang of the basics with a few drills, the 45-minute ride of 3 to 4 gentle miles will begin. Riders will experience Atlanta’s existing bicycle facilities, such as two-directional protected and single-directional bike lanes and sharrows, and learn to ride safely on streets without bike lanes by exercising their legal right to “take the lane.”

For registration information, click here.

Brook Byers Institute for Sustainable Systems Seminar Series: Anjali Thomas

April 13, 3 – 4 p.m., Economic Development Building (BBISS Suite 118)/Online

In the first of two seminars in this series, Anjali Thomas, associate professor and director of the Nunn School Program in Global Development, explores how “bureaucratic hurdles and identity politics shape water access in urban India.”

For additional information, click here.

Earth Day Org Fair and Celebration

April 18, 11 a.m. – 1 p.m., The Kendeda Building

Student organizations, academic departments, and groups around Atlanta will have tables set up in The Kendeda Building atrium and patio to promote a sustainable and environmentally conscious community. Enjoy free King of Pops, and bring a t-shirt, tote bag, or other item to be screen-printed with Earth Day designs. The Office of Sustainability will also have recovered shirts that can be used.

For additional information, click here.

Climate Action Plan Student Engagement Workshop

April 20, 5 – 6 p.m., Room 102, Clough Undergraduate Learning Commons

With a goal of reaching carbon neutrality by 2050, Georgia Tech is developing and implementing a comprehensive, cross-cutting Climate Action Plan. Students are invited to learn more about the plan and offer their thoughts on how the Institute can meet its climate goals during this engaging workshop hosted by the Office of Sustainability.

For additional information, click here.

Community Garden Ribbon Cutting

April 21, 2 – 3 p.m., Community Garden (Instructional Center Lawn)

Located along the Experiential Walkway, this event invites the Georgia Tech community to check out the newly renovated Community Garden and learn how to get involved.

For additional information, click here.

Film Screening: Making Pandemics at the Global Media Fest

April 23, 2 – 5 p.m., John Lewis Student Center

The French department in the School of Modern Languages will host a screening of Making Pandemics, a film that “seeks to understand the causes of this epidemic of pandemics” over the past four decades. The screening is free and open to the public.

Following the film, a panel of guest speakers will discuss its findings.

For more information, click here.

Sustainable-X Hangout

April 26, 3 – 4 p.m., Center for Sustainable Business Suite/Online

A partnership between the Ray C. Anderson Center for Sustainable Business and CREATE-X, Sustainable-X is a Sustainability Next Institute Strategic Plan project. With events occurring on the fourth Wednesday of every month, this session will examine social and environmental entrepreneurship and how to access resources for projects.

Brook Byers Institute for Sustainable Systems: Jenny McGuire

April 27, 3 – 4 p.m., Economic Development Building (BBISS Suite 118)/Online

Continuing the series hosted by the Brook Byers Institute for Sustainable Systems, Jenny McGuire, an associate professor in the School of Earth and Atmospheric Sciences, will host a seminar focused on “conserving the fabric of life given the complexities of global change.”

For additional information, click here.

Explore the Earth Month calendar for a comprehensive event lineup and updates. Campus groups, departments, and organizations interested in adding their sustainability-focused event to the Earth Month Calendar can submit this form or email Abby Bower.

Steven Gagliano - Communications Officer

Institute Communications

Georgia Tech Community Garden Reopening Celebration

Come celebrate the newly renovated Community Garden, located along the Experiential Walkway next to Rising Roll. Attendees are welcome to attend and learn more about the new garden and how to get involved with this great community space!

Conversations With Cabrera: Climate Action

Mar 29, 2023 —

L to R: Ángel Cabrera, Marilyn Brown, Tim Lieuwen, Andre Calmon & Brian Stone

In the latest installment of his unscripted video series, President Cabrera led a panel of Georgia Tech faculty including Marilyn Brown, Regents' and Brook Byers Professor of Sustainable Systems in the School of Public Policy, Tim Lieuwen, Regents’ Professor and executive director of the Strategic Energy Institute, Andre Calmon, assistant professor at the Scheller College of Business, and Brian Stone, professor at the School of City & Regional Planning, in a discussion on the policies, technologies, and planning that can help us achieve the best quality of life while also maintaining a global climate that remains within healthy limits.

Brent Verrill, Research Communications Program Manager

Spring2023 RBI Workshop on Packaging Innovation & the Circular Economy

Join the Renewable Bioproducts Institute for a one-and-a-half-day in-person workshop on "Packaging Innovation and the Circular Economy.“ Attendees will learn about cutting-edge developments in the packaging industry and an opportunity to network with leading researchers and peers from the industry. This unique workshop features speakers from:

Driving Change: Georgia Tech Experts Lead in Electrification of America’s Roads

Mar 21, 2023 — Atlanta

Top: Rich Simmons, Marilyn Brown, Gleb Yushin; Bottom: Valerie Thomas, Hailong Chen, Tim Lieuwen

Idling at a crossroads no longer, the automotive industry is embracing electrification like never before. With more electric vehicles purchased in 2022 than any year prior, consumers are beginning to follow their lead. Yet, while opportunity abounds, new challenges will require an innovative approach to ensure a sustainable and accessible electric future for all.

With historic investments from major players in the EV space, including Rivian, Kia, and Hyundai, the state of Georgia is uniquely positioned to serve as a leader in this effort. As the state's leading research institute, Georgia Tech is on the cutting edge of the movement.

The transportation sector is the largest greenhouse gas emitter in the U.S. at nearly 30%, with passenger vehicles accounting for around 80% of the sector's total output1 as of 2019. Electric vehicles are widely regarded as a budding solution to reduce emissions, but even as both demand and production continue to increase, EVs currently account for around 1% of the cars on America's roadways.

From the supply chain to the infrastructure needed to support alternative-fuel vehicles alongside consumer hesitancy, achieving the goals set by both the public and private sectors — including the Biden Administration's target of EVs making up at least 50% of new car sales by 2030 — will not be easy. Through research and development, policy, and collaboration, Tech experts are working toward finding solutions that will serve as catalysts during this transitionary period for the environment and the way Americans drive.

Steven Gagliano - Communications Officer

Institute Communications