BBISS Seminar Series - Dylan Brewer

Dylan Brewer, Ph.D., Assistant Professor, School of Economics, Georgia Institute of Technology

October 19, 2023, 3 - 4 PM ET

Hybrid Event - Teams Link

BBISS Offices, 760 Spring Street, Suite 118

Refreshments will be served.

BBISS Seminar Series - Bert Bras - 9/21/2023

Integrating Electric Vehicles into Households – A Decade of Assessing Benefits

Bert Bras, Ph.D., Associate Chair for Administration, Brook Byers Professorship in Energy and Environmental Systems, George W. Woodruff School of Mechanical Engineering, Georgia Institute of Technology

CEE Researchers Awarded $2.1 Million Grant to Ensure Cleaner, Safer Drinking Water

Aug 28, 2023 —

Researchers from Georgia Tech's School of Civil and Environmental Engineering received a $2.1 million grant from the U.S. Environmental Protection Agency (EPA) to investigate contaminants in drinking water.

The EPA is funding the research on the occurrence and concentration of pathogens and disinfection by-products and the environmental conditions favorable to their growth in drinking water distribution systems.

Carlton S. Wilder Associate Professor Ameet Pinto, the project's principal investigator, said disinfection is used to kill microorganisms to make drinking water safe for consumption. Yet, disinfecting to kill microorganisms can also result in formation of harmful disinfection by-products.

“Our key project goal is to shine a light on when, where, and why pathogens and disinfection by-products occur and co-occur in drinking water systems across the country,” Pinto said. “This will help water utilities better navigate the tradeoff of managing microbiological and chemical risks in drinking water and thus enhance the reliability of safe drinking water supply to their consumers.”

According to the EPA, opportunistic pathogens such as Legionella pneumophila, nontuberculous mycobacteria, and Pseudomonas aeruginosa can grow in drinking water systems and pose potential risks to public health. The occurrence of these and other microbial pathogens is also associated with contaminated storage facilities and other problems in water distribution systems such as backflow and low-pressure incidents.

If left untreated, these contamination events can lead to outbreaks of gastrointestinal, respiratory, and other waterborne illnesses. The disinfectants used to control these pathogens can cause additional problems by reacting with natural organic matter, bromide, and other contaminants to form disinfectant by-products, which also have the potential to be harmful to human health.

Georgia Tech is one of four institutions selected by the EPA to receive nearly $8.5 million in grant funding, along with the University of Minnesota, Michigan State University, and the University of Texas. The Georgia Tech team includes Turnipseed Family Chair & Professor Ching-Hua Huang and Assistant Professor Katy Graham.

Melissa Fralick | melissa.fralick@ce.gatech.edu

Climate Action Plan Student Engagement Workshop

Students are invited to join the Office of Sustainability to learn about the strategies included in the Georgia Tech Climate Action Plan and share their input.

*RSVP Required*

Climate Action Plan Campus Townhall

The Office of Sustainability will host a virtual townhall on Wednesday, Oct. 4 to share progress on the development of Georgia Tech's Climate Action Plan. All members of the campus community are invited to attend and share their feedback on the plan. Topics covered will include:

- Georgia Tech's Greenhouse Gas Inventory

- Climate Mitigation & Adaptation Strategies for Georgia Tech

Please register here to join the Zoom meeting.

Sustainability Fellows/Ambassadors Informational Panel

Interested in the Sustainability Fellows or Ambassadors programs? We'll give an overview and answer all your questions about participation in this info session!

Meet with a panel of past Sustainability Fellows and Ambassadors to learn from their experience and ask questions!

OUR PANEL:

- Azell Francis

- Suhas Yalamarti

- Phil Johnston

- Brandon Bermudez

Learn About Georgia Tech’s Participation in The New York Climate Exchange

Earlier this year, Georgia Tech was chosen as a core partner of the New York Climate Exchange – a first-of-its-kind international center for the rapid development of urban climate solutions

Environmental Science (ENVS) Undergraduate Degree Launch Event

You're invited to the Environmental Science (ENVS) launch on Friday August 25th from 3-5 pm on the Kendeda Porch. See attached flier for more information.

Aluminum Materials Show Promising Performance for Safer, Cheaper, More Powerful Batteries

Jul 19, 2023 — Atlanta, GA

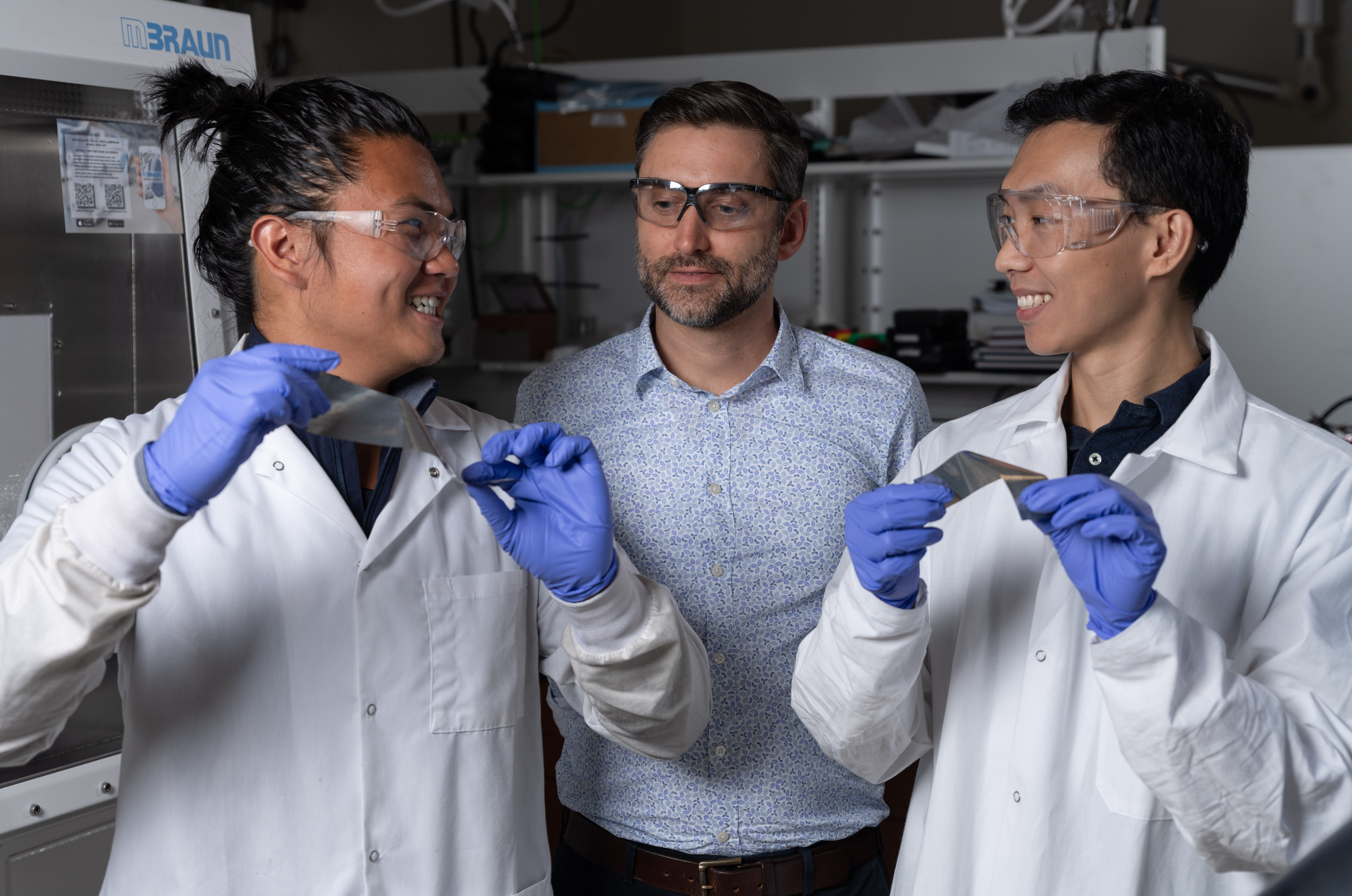

Graduate student researcher Yuhgene Liu holds an aluminum material for solid-state batteries.

A good battery needs two things: high energy density to power devices, and stability, so it can be safely and reliably recharged thousands of times. For the past three decades, lithium-ion batteries have reigned supreme — proving their performance in smartphones, laptops, and electric vehicles.

But battery researchers have begun to approach the limits of lithium-ion. As next-generation long-range vehicles and electric aircraft start to arrive on the market, the search for safer, cheaper, and more powerful battery systems that can outperform lithium-ion is ramping up.

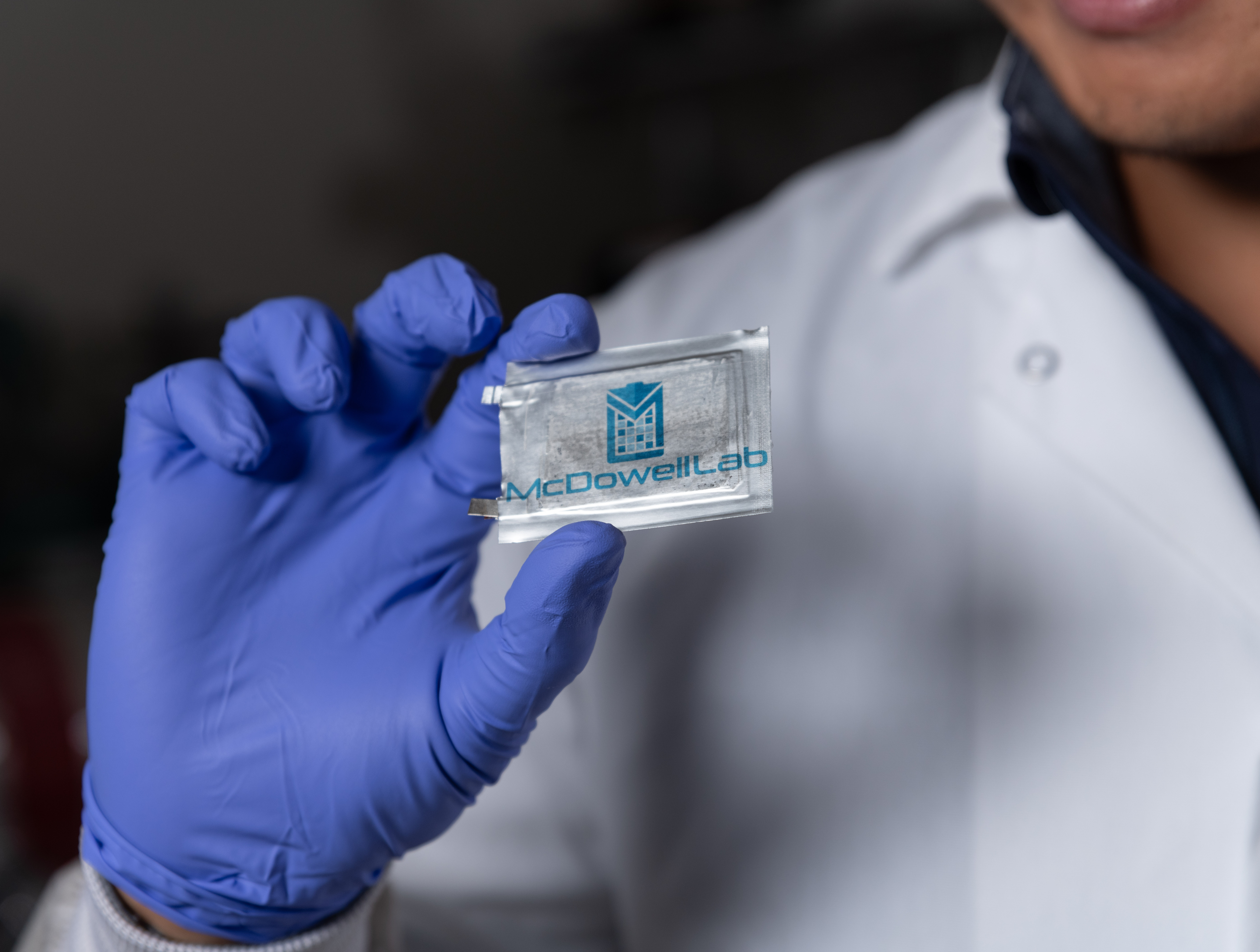

A team of researchers from the Georgia Institute of Technology, led by Matthew McDowell, associate professor in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering, is using aluminum foil to create batteries with higher energy density and greater stability. The team’s new battery system, detailed in Nature Communications, could enable electric vehicles to run longer on a single charge and would be cheaper to manufacture — all while having a positive impact on the environment.

“We are always looking for batteries with higher energy density, which would enable electric vehicles to drive for longer distances on a charge,” McDowell said. “It’s interesting that we can use aluminum as a battery material, because it’s cost-effective, highly recyclable, and easy to work with.”

The idea of making batteries with aluminum isn’t new. Researchers investigated its potential in the 1970s, but it didn’t work well.

When used in a conventional lithium-ion battery, aluminum fractures and fails within a few charge-discharge cycles, due to expansion and contraction as lithium travels in and out of the material. Developers concluded that aluminum wasn’t a viable battery material, and the idea was largely abandoned.

Now, solid-state batteries have entered the picture. While lithium-ion batteries contain a flammable liquid that can lead to fires, solid-state batteries contain a solid material that's not flammable and, therefore, likely safer. Solid-state batteries also enable the integration of new high-performance active materials, as shown in this research.

The project began as a collaboration between the Georgia Tech team and Novelis, a leading manufacturer of aluminum and the world’s largest aluminum recycler, as part of the Novelis Innovation Hub at Georgia Tech. The research team knew that aluminum would have energy, cost, and manufacturing benefits when used as a material in the battery’s anode — the negatively charged side of the battery that stores lithium to create energy — but pure aluminum foils were failing rapidly when tested in batteries.

The team decided to take a different approach. Instead of using pure aluminum in the foils, they added small amounts of other materials to the aluminum to create foils with particular “microstructures,” or arrangements of different materials. They tested over 100 different materials to understand how they would behave in batteries.

“We needed to incorporate a material that would address aluminum’s fundamental issues as a battery anode,” said Yuhgene Liu, a Ph.D. student in McDowell’s lab and first author on the paper. “Our new aluminum foil anode demonstrated markedly improved performance and stability when implemented in solid-state batteries, as opposed to conventional lithium-ion batteries.”

The team observed that the aluminum anode could store more lithium than conventional anode materials, and therefore more energy. In the end, they had created high energy density batteries that could potentially outperform lithium-ion batteries.

“One of the benefits of our aluminum anode that we're excited about is that it enables performance improvements, but it also can be very cost-effective,” McDowell said. “On top of that, when using a foil directly as a battery component, we actually remove a lot of the manufacturing steps that would normally be required to produce a battery material.”

Short-range electric aircraft are in development by several companies, but the limiting factor is batteries. Today’s batteries do not hold enough energy to power aircraft to fly distances greater than 150 miles or so. New battery chemistries are needed, and the McDowell team’s aluminum anode batteries could open the door to more powerful battery technologies.

“The initial success of these aluminum foil anodes presents a new direction for discovering other potential battery materials,” Liu said. "This hopefully opens pathways for reimagining a more energy-optimized and cost-effective battery cell architecture.”

The team is currently working to scale up the size of the batteries to understand how size influences the aluminum’s behavior. The group is also actively exploring other materials and microstructures with the goal of creating very cheap foils for battery systems.

“This is a story about a material that was known about for a long time, but was largely abandoned early on in battery development,” McDowell said. “But with new knowledge, combined with a new technology — the solid-state battery — we've figured out how we can rejuvenate the idea and achieve really promising performance.”

Citation: Liu, Y., Wang, C., Yoon, S.G. et al. Aluminum foil negative electrodes with multiphase microstructure for all-solid-state Li-ion batteries. Nat Commun 14, 3975 (2023).

DOI: https://doi.org/10.1038/s41467-023-39685-x

Funding: Support is acknowledged from Novelis, Inc. M.T.M. acknowledges support from a Sloan Research Fellowship in Chemistry from the Alfred P. Sloan Foundation. This work was performed in part at the Georgia Tech Institute for Electronics and Nanotechnology, a member of the National Nanotechnology Coordinated Infrastructure (NNCI), which is supported by the National Science Foundation (ECCS-2025462).

Writer: Catherine Barzler

Photography: Rob Felt

Ph.D. student Yuhgene Liu, associate professor Matthew McDowell, and postdoctoral researcher Congcheng Wang in McDowell's lab at Georgia Tech.

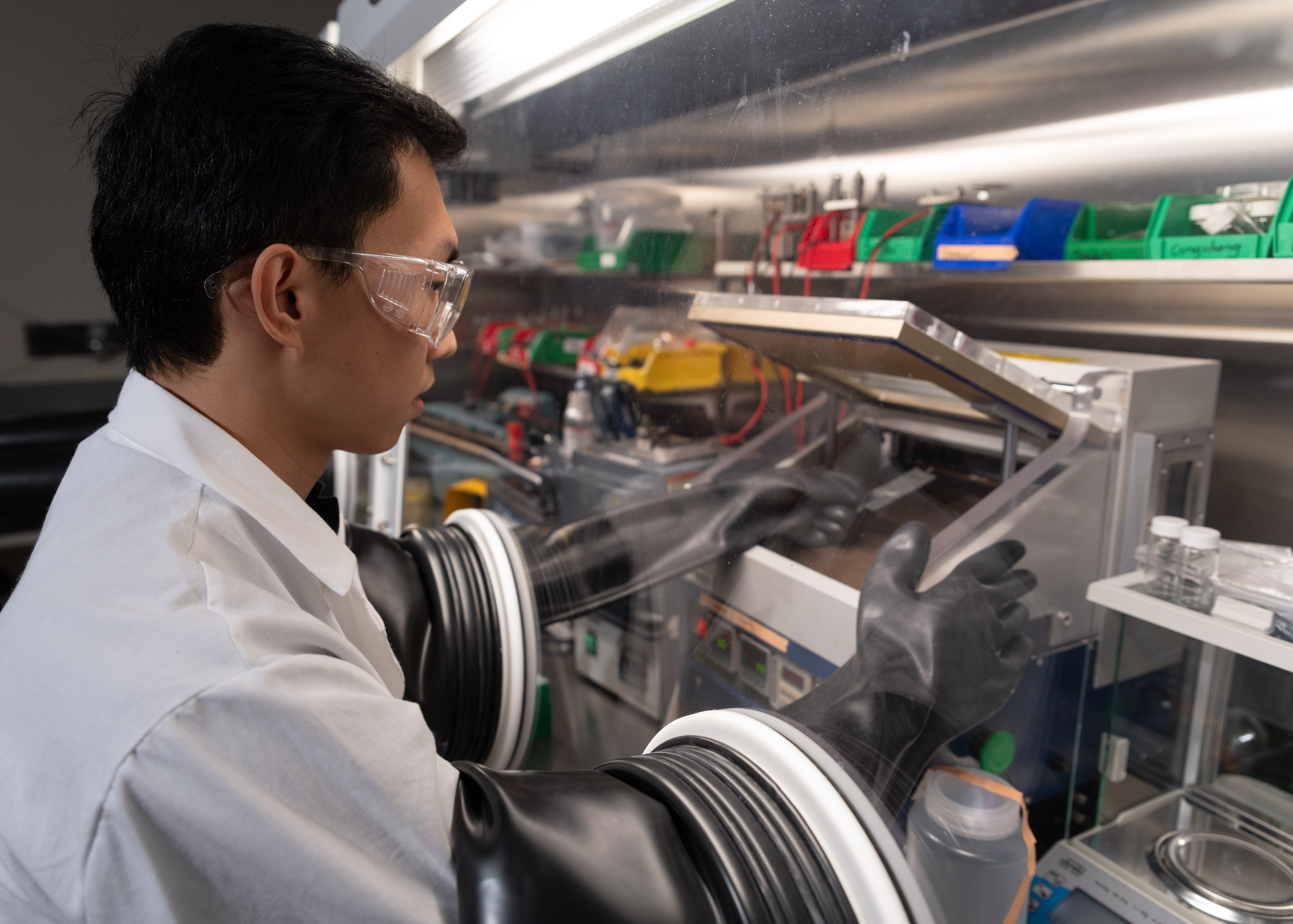

Postdoctoral researcher Congcheng Wang builds a battery cell.

A solid-state battery built in McDowell’s laboratory.

Catherine Barzler, Senior Research Writer/Editor

Institute Communications