From keeping warm in the winter to doing laundry, heat is crucial to daily life. But as the world grapples with climate change, buildings’ increasing energy consumption is a critical problem. Currently, heat is produced by burning fossil fuels like coal, oil, and gas, but that will need to change as the world shifts to clean energy.

Georgia Tech researchers in the George W. Woodruff School of Mechanical Engineering (ME) are developing more efficient heating systems that don’t rely on fossil fuels. They demonstrated that combining two commonly found salts could help store clean energy as heat; this can be used for heating buildings or integrated with a heat pump for cooling buildings.

The researchers presented their research in “Thermochemical Energy Storage Using Salt Mixtures With Improved Hydration Kinetics and Cycling Stability,” in the Journal of Energy Storage.

Reaction Redux

The fundamental mechanics of heat storage are simple and can be achieved through many methods. A basic reversible chemical reaction is the foundation for their approach: A forward reaction absorbs heat and then stores it, while a reverse reaction releases the heat, enabling a building to use it.

ME Assistant Professor Akanksha Menon has been interested in thermal energy storage since she began working on her Ph.D. When she arrived at Georgia Tech and started the Water-Energy Research Lab (WERL), she became involved in not only developing storage technology and materials but also figuring out how to integrate them within a building. She thought understanding the fundamental material challenges could translate into creating better storage.

“I realized there are so many things that we don't understand, at a scientific level, about how these thermo-chemical materials work between the forward and reverse reactions,” she said.

The Superior Salt

The reactions Menon works with use salt. Each salt molecule can hold a certain number of water molecules within its structure. To instigate the chemical reaction, the researchers dehydrate the salt with heat, so it expels water vapor as a gas. To reverse the reaction, they hydrate the salt with water, forcing the salt structure’s expansion to accommodate those water molecules.

It sounds like a simple process, but as this expansion/contraction process happens, the salt gets more stressed and will eventually mechanically fail, the same way lithium-ion batteries only have so many charge-discharge cycles.

“You can start with something that's a nice spherical particle, but after it goes through a few of these dehydration-hydration cycles, it just breaks apart into tiny particles and completely pulverizes or it overhydrates and agglomerates into a block,” Menon explained.

These changes aren’t necessarily catastrophic, but they do make the salt ineffective for long-term heat storage as the storage capacity decreases over time.

Menon and her student, Erik Barbosa, a Ph.D. student in ME, began combining salts that react with water in different ways. After testing six salts over two years, they found two that complemented each other well. Magnesium chloride often fails because it absorbs too much water, whereas strontium chloride is very slow to hydrate. Together, their respective limitations can mutually benefit each other and lead to improved heat storage.

“We didn't plan to mix salts; it was just one of the experiments we tried,” Menon said. “Then we saw this interactive behavior and spent a whole year trying to understand why this was happening and if it was something we could generalize to use for thermal energy storage.”

The Energy Storage of the Future

Menon is just beginning with this research, which was supported by a National Science Foundation (NSF) CAREER Award. Her next step is developing the structures capable of containing these salts for heat storage, which is the focus of an Energy Earthshots project funded by the U.S. Department of Energy’s (DOE) Office of Basic Energy Sciences.

A system-level demonstration is also planned, where one solution is filling a drum with salts in a packed bed reactor. Then hot air would flow across the salts, dehydrating them and effectively charging the drum like a battery. To release that stored energy, humid air would be blown over the salts to rehydrate the crystals. The subsequently released heat can be used in a building instead of fossil fuels. While initiating the reaction needs electricity, this could come from off-peak (excess renewable electricity) and the stored thermal energy could be deployed at peak times. This is the focus of another ongoing project in the lab that is funded by the DOE’s Building Technologies Office.

Ultimately, this technology could lead to climate-friendly energy solutions. Plus, unlike many alternatives like lithium batteries, salt is a widely available and cost-effective material, meaning its implementation could be swift. Salt-based thermal energy storage can help reduce carbon emissions, a vital strategy in the fight against climate change.

“Our research spans the range from fundamental science to applied engineering thanks to funding from the NSF and DOE,” Menon said. “This positions Georgia Tech to make a significant impact toward decarbonizing heat and enabling a renewable future.”

Erik Barbosa and Madeline Morrell (PhD students) analyze water vapor storage and release in salts. Photo by: Allison Carter

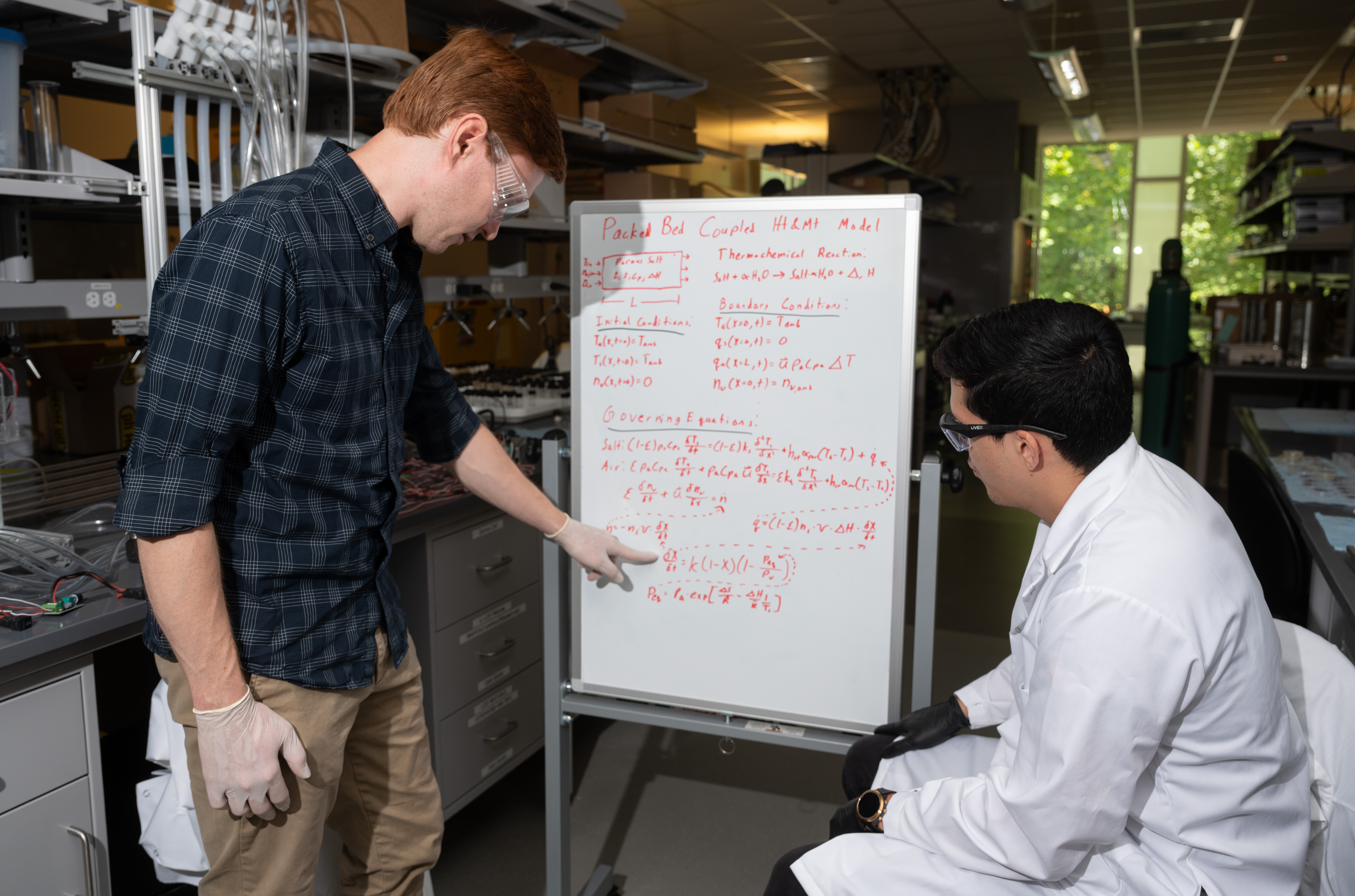

Michael Adams (postdoc) and Erik Barbosa discuss a heat and mass transfer model for a packed bed reactor of salts. Photo by: Allison Carter

The thermal energy storage team in Menon's lab. Photo by: Allison Carter